55

LASER MAINTENANCE

WARNING!

Do not watch directly into the laser ray. If you do, you risk serious injuries to your

eyes. Read and observe all safety rules about the laser.

Check that the laser is clean and wipe the dust if necessary.

1. Switch off the mitre saw and the laser. Disconnect the feeder cable.

2. Wipe the dust using a soft, clean mop

LUBRICATION

All bearings are permanently lubricated from factory; you don’t need to grease them.

WARNING!

Before any repair or maintenance disconnect the feeder cable.

INSPECTION AND REPLACEMENT OF MOTOR BUSHES

WARNING: before inspecting the brushes disconnect the feeder cable.

Brushes’ duration is variable. It depends on the amount of work done by the motor. Verify the

brushes after the first 20 hours of use of a new machine or after mounting new brushes.

After the first check, inspect them every 10 hours of work, until the replacement becomes

necessary.

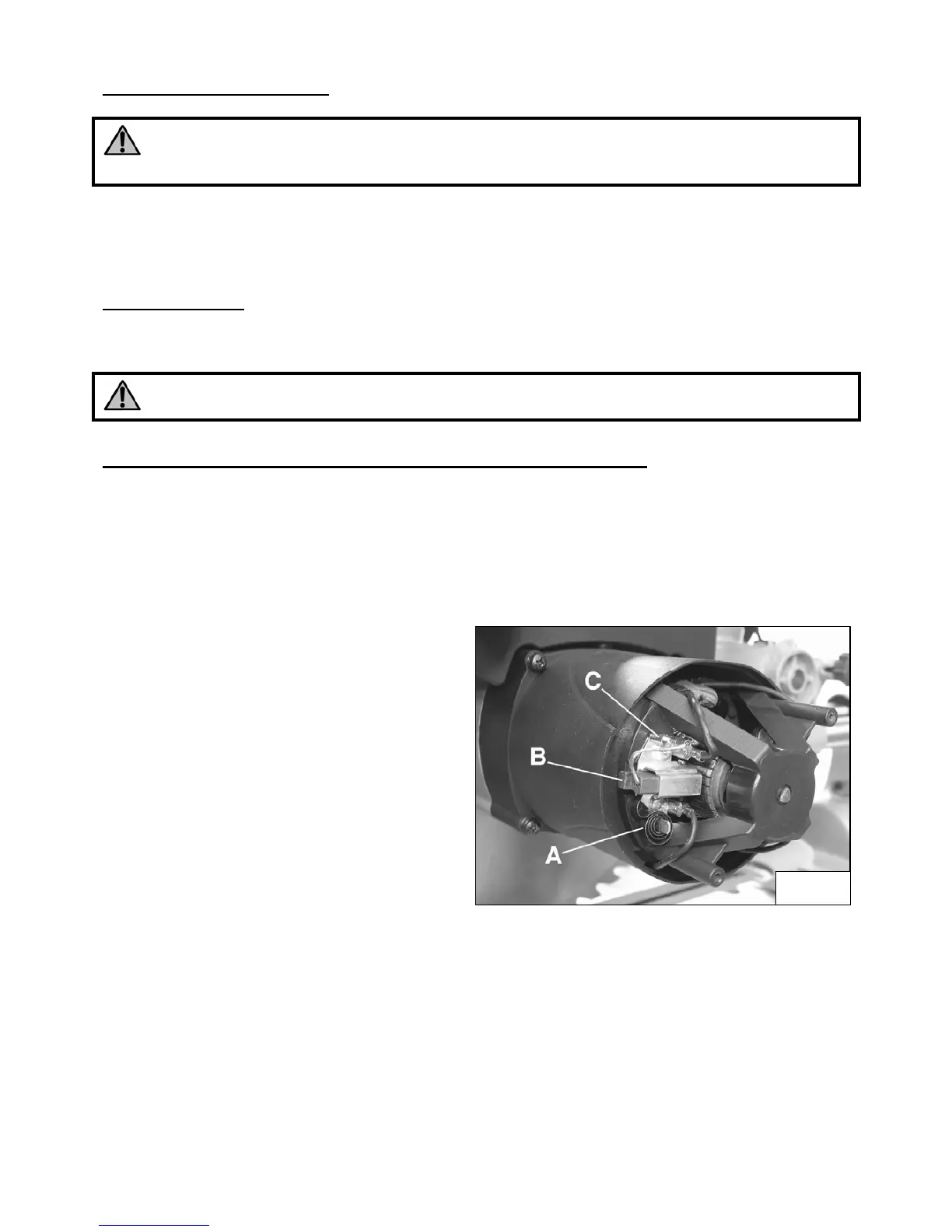

The brush-sockets Fig.18 are located inside

the motor carter. Replace each brush when

the carbon left is less than 5mm, or whenever

a spring or a wire are burned or damaged. If

the brushes are found usable at the

inspection, remount them in the same position

they were before.

Proceed as follows:

1. Open and unscrew the two screws fixing

the motor carter.

2. remove the carter and then the brushes

(B) fig.18. Press the spring (A) to release the brushes, disconnect the cable (C).

3. take off each brush (B) check it and replace it if necessary. Replace both brushes also if

only one is worn out.

Note : After controlling the brushes, if you do not replace them, make sure to reposition them in

the same position as before.

4. Position the brushes in the motor. Re-position the spring (A)

5. Run the machine for about 5 - 10 minutes to allow the brushes to adapt to their position. If

these are not correctly assembled the motor can be seriously damaged. While the brushes

adapt to their position you can notice sparks coming out of the motor: this is normal for new

brushes

Fig.18

Loading...

Loading...