•

Permit no smoking or other ignition sources in,

or within thirty feet of, a natural gas vehicle.

•

Have CO

2

fire extinguishers (ABC minimum)

located in a highly visible and easily accessible

location.

•

Use Purple-K powder (PKP) or a similar dry

powder to extinguish an LNG fire. Do not at-

tempt use water around an LNG fire.

•

Always purge the fuel lines before performing

maintenance or repairs on a natural gas fuel

system. Refer to the system manufacturer’s

service manual or the vehicle’s workshop

manuals for the proper purging procedure.

•

Always use a natural gas detector to test the

system for leaks, whether an odor is present or

not. Routinely inspect the fuel filtering and

regulating mechanisms, and the fuel lines. An

approved natural gas bubble solution can be

used to pinpoint the exact location of leaks. Do

not use soap and water. Soap and water can

cause premature failure of the O-rings in the

system.

•

Make sure black caps are always on the PRD

vent lines to reduce water build up in lines.

•

Do not store a natural gas vehicle indoors for

any extended period of time. Do not bring a

natural gas vehicle indoors unless the work-

shop is equipped with a methane detection and

ventilation system.

In Case of Emergency

If a vehicle has sustained damage or a leak has

been discovered:

1.

Turn the ignition switch off, and set the parking

brake.

2.

Exit the vehicle leaving as many doors and win-

dows open as possible. Get at least 30 feet from

the vehicle, and allow it to vent until it is safe to

do the steps below.

3.

Remove all ignition sources from the area sur-

rounding the vehicle.

4.

If it is safe to do so, close all fuel shutoff valves.

5.

Use a natural gas detector, or approved NG

bubble solution, to identify leaks in the fuel sys-

tem.

Natural Gas Fuel Tank Filling

Procedures

CNG Vehicle Fueling

CNG is moved from the fuel station storage tanks to

the vehicle cylinders through a metered dispenser.

During fueling, as pressure inside of the vehicle cyl-

inders increases, so does the temperature. The dis-

penser shuts off when it determines the CNG cylin-

ders are full.

CNG fuel cylinders cannot be filled to their full capac-

ity of 3600 psi (24 800 kPa) in cooler weather. Since

temperature change causes gas to expand and con-

tract, less pressure in the cylinders on a cold day is

equal to the same amount of gas at a higher pres-

sure on a warm day. The fuel station dispenser has a

temperature-pressure compensating device, which

accounts for ambient temperature during fueling. See

Table 25.1 for approximate full cylinder pressures at

various temperatures.

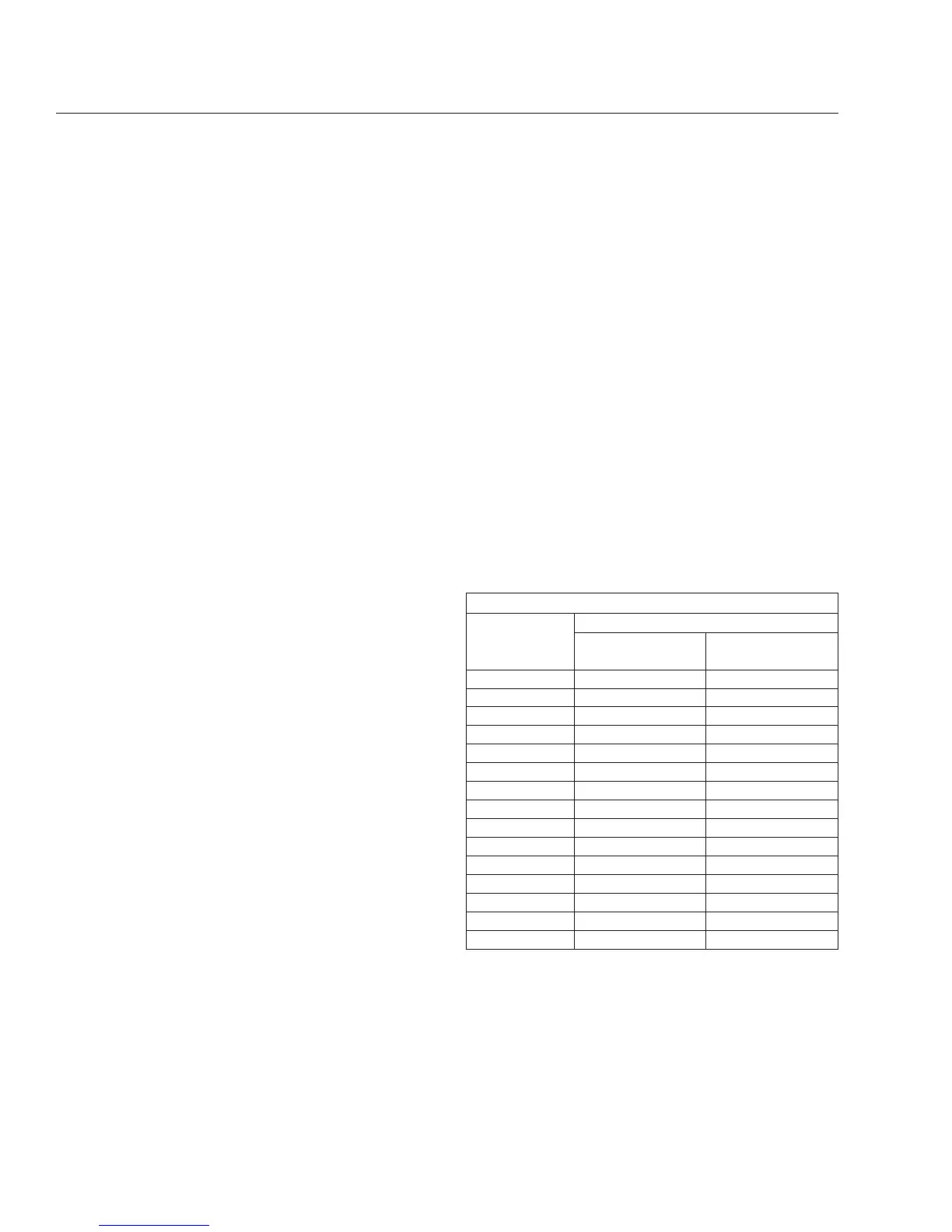

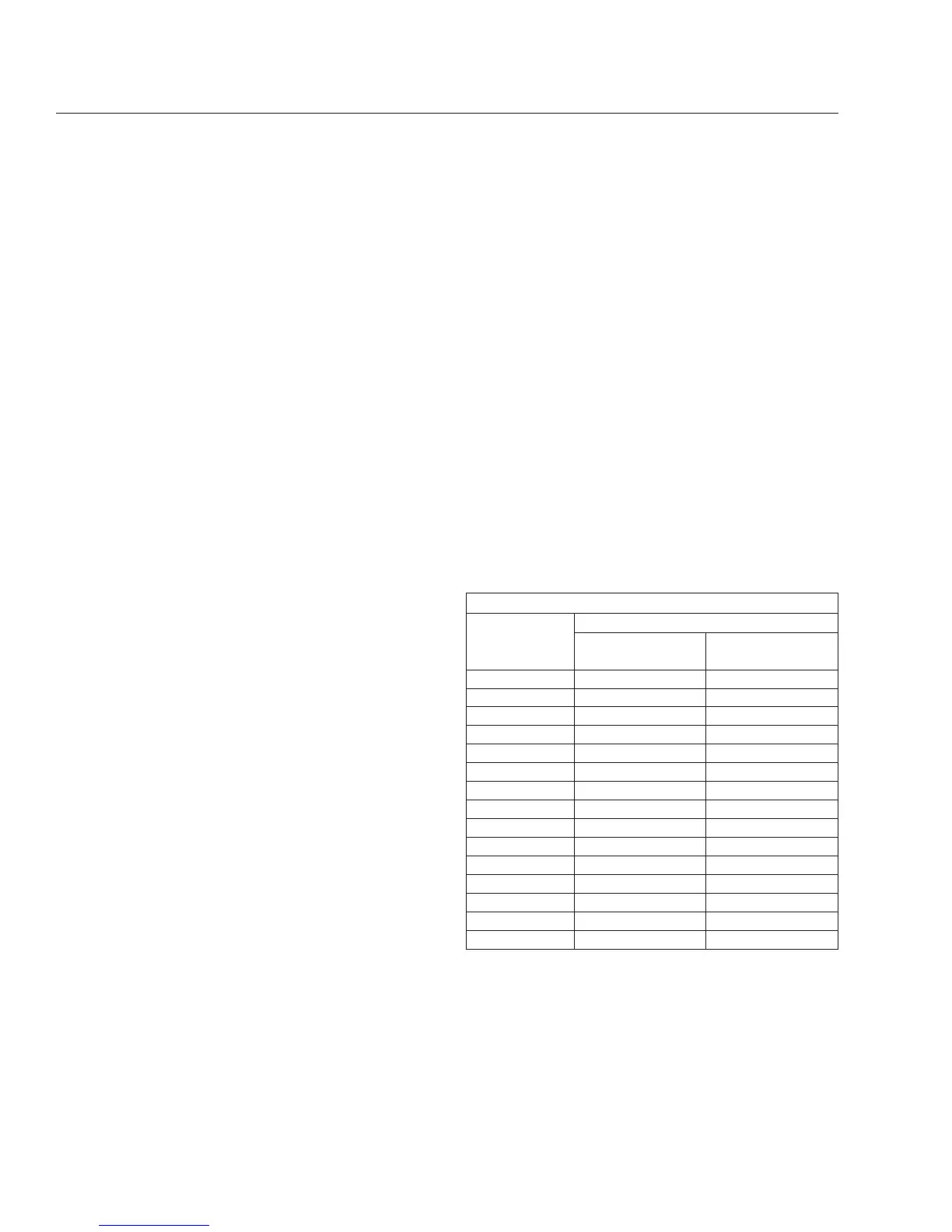

CNG Temperature/Pressure Compensation Values

Temperature:

°F (°C)

Fill Station Pressure Set Point

3000 psi (20 684

kPa) Set Point

3600 psi (24 821

kPa) Set Point

100 (37.8) 3415 (23 546) 4086 (28 172)

90 (32.2) 3276 (22 587) 3909 (26 952)

80 (26.7) 3138 (21 636) 3754 (25 883)

70 (21.1) 3000 (20 684) 3600 (24 821)

60 (15.6) 2861 (19 726) 3445 (23 752)

50 (10) 2723 (18 774) 3288 (22 670)

40 (4.4) 2584 (17 816) 3131 (21 587)

30 (-1.1) 2446 (16 865) 2973 (20 498)

20 (-6.7) 2307 (15 906) 2814 (19 402)

10 (-12.2) 2169 (14 955) 2655 (18 306)

0 (-17.8) 2031 (14 003) 2495 (17 202)

-10 (-23.3) 1893 (13 052) 2336 (16 106)

-20 (-28.9) 1755 (12 100) 2180 (15 031)

-30 (34.4) 1616 (11 142) 2024 (13 955)

-40 (-40) 1477 (10 184) 1868 (12 879)

Table 25.1, CNG Temperature/Pressure Compensation

Values

Use the following steps to fuel a CNG vehicle.

1.

Shut down the engine and apply the parking

brake.

Natural Gas Vehicles

25.3

Loading...

Loading...