S90-010 M FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 14 MAINTENANCE

reads 4.98 Vdc, you can be assured that the voltage at the

subsequent connections for the remaining boards will be

lower yet. The voltage will need to be corrected for proper

operation of the system. The cause for a low voltage

reading could be:

• The Quantum™ power supply may need

adjustment (see the section on power supplies).

• The Power-I/O communications harness has a

problem (a new harness may be needed).

• A problem may exist with one of the I/O boards

(Digital or Analog).

• If the power LED is not lighted, check the cable

for proper connectivity. Note: Each board

provides the necessary connections to feed

all signals to the following connectors. If the

auxiliary Analog or Digital Board is not

present then a jumper plug (see

Recommended Spare Parts List) must be

installed to daisychain the signals.

The most common symptom that is be exhibited by a low

+5 Vdc voltage to the Digital Boards is an alarm message

that reads "Digital Board Reset Shutdown".

Active LED

The Digital Boards have an “Active” LED indicator on the

board that blinks when the board’s software is running.

If the “Active” LED is not blinking, check to ensure that the

EPROM is installed properly. The EPROM is located in

chip slot U8, next to the power connector.

Digital Inputs

A Digital Input is the portion of the hardware that allows

devices such as limit switches, relay contacts, and level

switches, to interface with the Quantum™. The software

program within the Quantum™ is constantly “looking” at

these Input channels, via communications, and based

upon whether a control voltage is present or not, will

provide the necessary control for an associated Output

channel. For instance, if a control voltage is present on the

Oil Level Sensor input, the software will determine that the

Separator has sufficient oil level for the oil heaters to be

energized (if the temperature of the oil is also sensed to

be low. Temperature sensing will be discussed in the

Analog Input section).

There are two possible varieties of Digital Input modules

used on standard compressor control packages. One is for

120 Volt controls, and the other is for 240 volt controls.

Both of these module styles are yellow in color. A side

profile of these modules is shown below:

These Input modules, can be identified as to their

operating voltage by looking at either the side, as shown

above, or from the top. You will notice the module

operating voltage printed on the top, and the voltage range

printed on the side.

Never plug a 120 Volt Input module into a 240 Volt

system, and vice-versa. Never plug an Output module into

a position designated for an Input module.

You will notice that when a module is plugged into the

Digital board, there is a fuse located directly adjacent to

the module. This fuse is of the plugable variety, and must

be plugged into the “IN” position for an Input module.

Digital Outputs

A Digital Output is the portion of the hardware that the

Quantum™ is to control (energize). These devices include

solenoids, relay coils, and heaters to be energized, based

upon the logic within the Quantum™ software program.

There is one variety of Digital Output modules used on

standard compressor control packages. This one module

will handle both 120 Volt controls, and 240 volt controls.

This module is black in color. A side profile of this module

is shown below:

Although this Output module is labeled as 280 VAC on the

top, and on the side, it can be used on both 120 and 240

volt applications.

Never plug an Input module into a position designated for

an Output module.

You will notice that when a module is plugged into the

Digital Board, there is a fuse located directly adjacent to

the module. This fuse is of the plugable variety, and must

be plugged into the “OUT” position for an Output module.

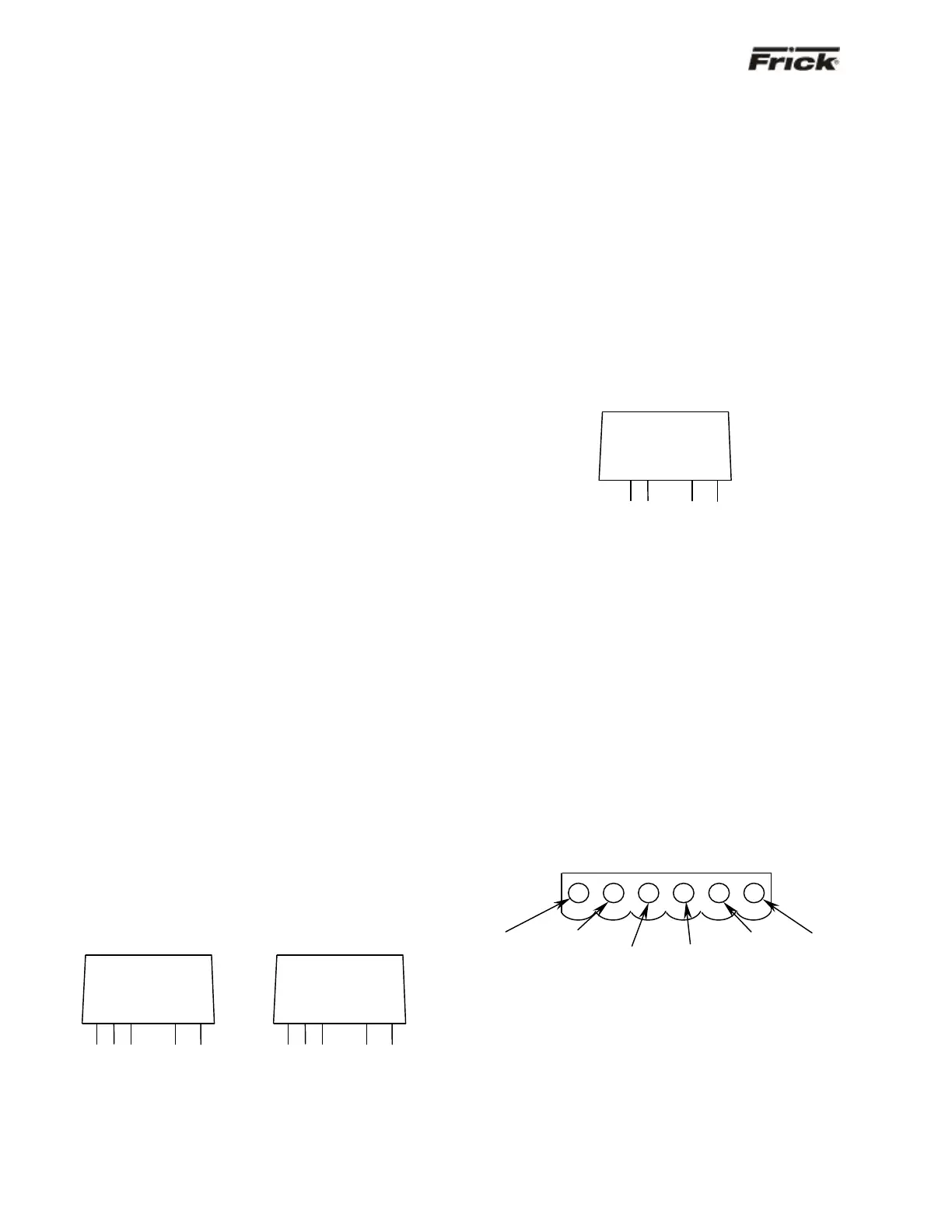

Checking the Digital Inputs and Outputs

Some problems that may be encountered involve

troubleshooting the digital inputs and outputs. The Digital

I/O (Input / Output) Boards have six Digital I/O (DIO) board

connectors labeled P1 through P6. The Input and Output

modules are wired to a DIO connector plug. Position 3

provides power and position 4 is a neutral on the DIO

connectors. Positions 1, 2, 5, and 6 are signal

connections, as shown below:

The Digital I/O board’s I/O modules are configured by

proper module selection, AC or DC, operating voltage,

input or output, and moving the fuse to the “in” or “out”

position. An LED is associated with each module and

displays the state of each module. A lighted LED

represents an Input that is “High”, receiving a signal or an

Output that is “On”. Each of the sixteen modules has a

corresponding software configuration screen.

If a properly configured Digital I/O is not responding

correctly, first look at the Digital Board on the “Service

Screen” (on page 18) and check if the module is on. If it is

5

4

3

5VDC LOGIC

AC INPUT

5

4

3

5VDC LOGIC

AC INPUT

4

3

DC CONTROL

AC OUTPUT

120/240 VAC Output

HOT NEUTRAL

Position

1 Signal

Position

2 Signal

Position

3 Signal

Position

4 Signal

Loading...

Loading...