S90-010 M FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 40 MAINTENANCE

SYMPTOM PROBABLE CAUSES and CORRECTIONS

CONTROL PANEL DOES NOT

RESPOND TO REMOTE CONTROL

SIGNALS

Digital I/O Board 2, Inputs 3 through 5 can be used to operate the compressor

from a remote location. NOTE: Check the Operating display to verify that

the compressor and the Slide Valve are in REMOTE.

If the Input 3 (MOD 3) does not turn on, check if the LED (D3) is lit when it

should be. If it isn’t, check the fuse (F3) and if the fuse is OK, check the input

module (MOD 3).

If the Input 4 (MOD 4) does not turn on, check if the LED (D4) is lit when it

should be. If it isn’t, check the fuse (F4) and if the fuse is OK, check the input

module (MOD 4).

If the Input 5 (MOD 5) does not turn on, check if the LED (D5) is lit when it

should be. If it isn’t, check the fuse (F5) and if the fuse is OK, check the input

module (MOD 5).

MOTOR LOAD CONTROL(FORCED

UNLOAD) OCCURS AT HIGH MOTOR

AMPS

The current transformer is used to convert the AC motor amps to a DC voltage

signal for the microprocessor. If the %FLA reading from the Operating display

is incorrect, contact the Frick

Service Department.

MOTOR LOAD CONTROL(FORCED

UNLOAD) OCCURS AT LOW MOTOR

AMPS

The current transformer is used to convert the AC motor amps to a DC voltage

signal for the microprocessor. If the %FLA reading from the Operating display

is incorrect, contact the Frick

Service Department.

PRESSURES ON THE OPERATING

SCREEN DO NOT APPEAR CORRECT

TEST 1 - Shut down the compressor and allow pressures to equalize.

Discharge pressure and oil pressure should have the same reading.

TEST 2 - If either oil pressure or discharge pressure read different pressures,

one or both transducers are at fault. Valve off the suction transducer from the

unit and open the vent valve on transducer manifold to atmosphere. If the

suction transducer reads atmospheric pressure, then the transducer in Test 1,

which agrees with the suction transducer, is correct. The transducer which

disagrees is defective.

NOTE: Reference the Pressure Transducer Conversion Data Chart.

COMPRESSOR WITH SLIDE VALVE

DOES NOT AUTOMATICALLY LOAD OR

UNLOAD*

Verify that the Slide Valve Mode [AUTO] key has been pressed and AUTO

appears under Slide Valve Mode on the “Operating Status” screen.

If the problem persists, see the Troubleshooting section SLIDE VALVE DOES

NOT LOAD and/or UNLOAD.

COMPRESSOR THAT STEPS ON

CAPACITY DOES NOT

AUTOMATICALLY LOAD OR UNLOAD*

Verify that the Capacity Mode [AUTO] key has been pressed and AUTO

appears under Capacity Mode on the “Operating Status” screen.

If the problem persists, see the Troubleshooting section COMPRESSOR

DOES NOT LOAD and/or UNLOAD.

* If applicable

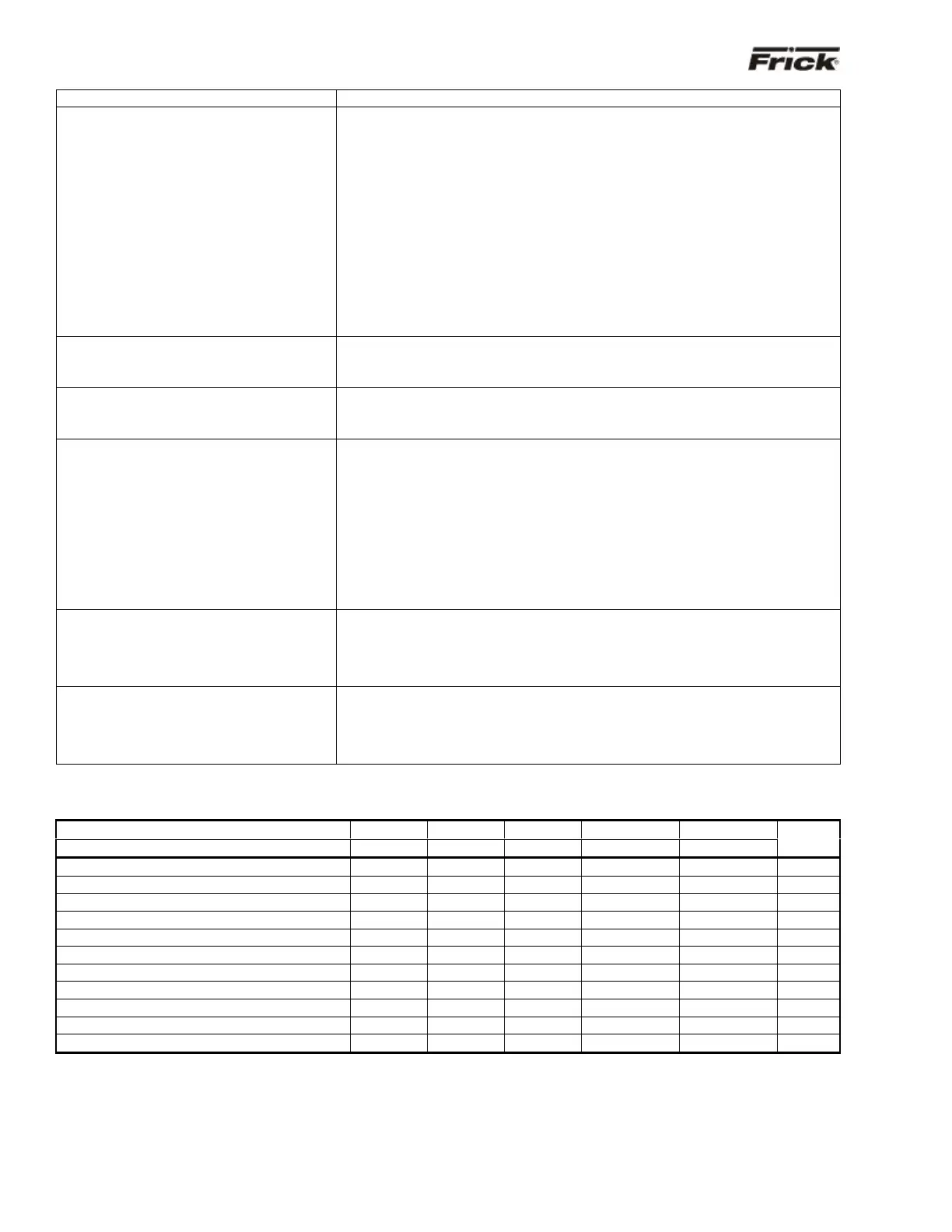

COMPRESSOR MODEL DIFFERENCES

FRICK

RWB, SC RXB* RXF RDB 3-Step RDB 4-Step

GRAM GSV, YLC GST* GSB 3-Step

Other

Slide Valve Reading

0-100% 0-100% 0-100% N/A N/A 0-100%

Slide Valve Setpoints

Yes Yes Yes N/A N/A Yes

Slide Valve Calibration

Yes Yes Yes N/A N/A Yes

Capacity Reading

N/A N/A N/A 50,75,100 25,50,75,100 N/A

Slide Stop Reading

2.2-5.0 2.2,3.5,5.0 2.2,3.5,5.0 N/A N/A N/A

Slide Stop Calibration

N/A N/A N/A N/A N/A N/A

DX Circuit Option

Yes Yes Yes N/A N/A Yes

Hot Gas Bypass/SV Setpoints Option

Yes Yes Yes N/A N/A Yes

Remote Slide Valve Position Option

Yes Yes Yes N/A N/A Yes

Sequence by Comp. Sequencing

Yes Yes Yes N/A N/A Yes

Forced unload Inhibit load delay setpoint

N/A N/A N/A Yes Yes N/A

* Or other variable VI

N/A = Not Applicable

Loading...

Loading...