S90-010 M FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 30 MAINTENANCE

In order to properly measure the DC power, it must be

checked at the Quantum™ controller, and verified for

acceptable total voltage drop at the end of the daisychain

(last I/O board). For the +5 Vdc (on either power supply), if

the voltage at the Quantum™ is in the range of +5.04 to

+5.08 (+5.06 is ideal), and the voltage being read at the

last I/O board is greater than +4.98 V, it can be assumed

that the +5 V power is correctly adjusted. For the +12 Vdc

(on either power supply), if the range at the last I/O board

is between +11.8 and +12.2 Vdc (+12.00 is ideal), it can

be assumed that the +12 V power is correct. The range for

this voltage is not critical at the Quantum™, and the

reading does not need to be taken there. Remember that

the +12 Vdc cannot be adjusted on the Condor.

CAUTION! Measuring and adjusting the power supply

voltages require the control power switch to be energized.

Extreme care must be observed when taking any

readings, as 120 or 230 VAC (depending on incoming

system voltage) is present within the power supply.

Adjusting the supply requires the use of a small

screwdriver with an insulated shaft, refer to NS-10-02)

inserted into the supply to access an adjusting

potentiometer. It is possible for the screwdriver (and the

person making the adjustment) to come into contact with

potentially lethal voltages.

To perform measurements and adjustments on the power

supply voltages, use a reliable Digital Volt Meter (DVM).

The DVM should be accurate to 1/100 of a volt DC. With

the control power switch turned "ON", wait until the

"Operating Screen" appears. This is because the graphics

required to create this screen will draw more current than

when the screen is showing the normal "POST" style

messages during a boot up. If the screen never appears

however (possibly due to a voltage problem), you will need

to proceed regardless of what is or is not displayed.

Ensure that the meter is set to the proper range (DC, 0-50

V or equivalent), as well as observing proper wire polarity.

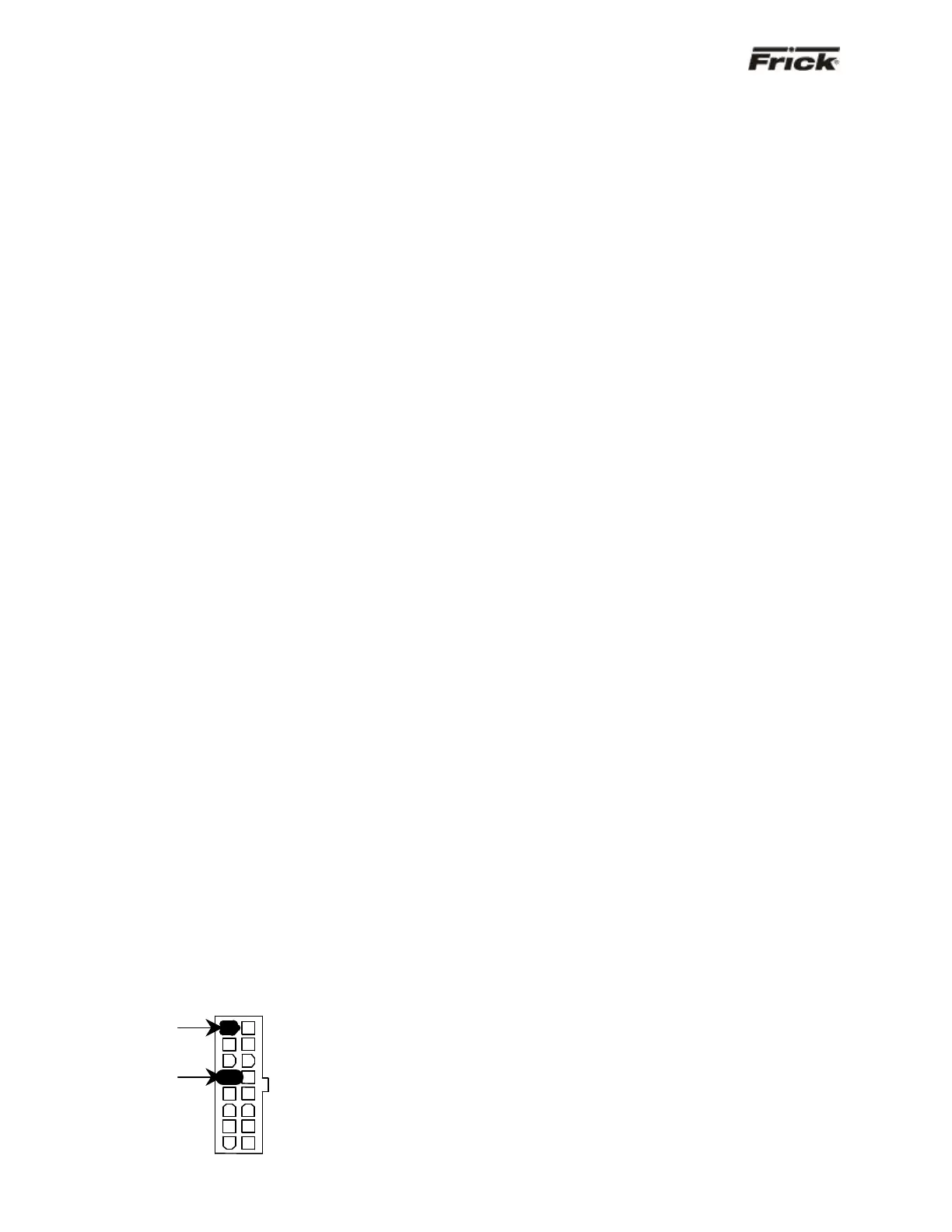

Measure the +5 Vdc first. If you have a Quantum™ 3

controller, refer to the pictorial drawing of it on the

following page for the exact location of the measurement

point. Place the negative lead on the common (return) pin,

and the positive lead on the +5 Vdc pin as shown. Verify

that the DVM is displaying in the range of +5.04 to +5.08

(+5.06 is ideal). If the reading is outside of this range, then

using a thin, flat bladed screwdriver, insert the tip into the

access hole for the appropriate voltage potentiometer

(refer to the Quantum™ Panel D.C. Power Supply

Layouts). While watching the DVM, slowly rotate the

screwdriver blade clockwise to increase the voltage or

counter-clockwise to decrease. Once the voltage has been

adjusted, remove the DVM probes from the Quantum™,

and install them into the white connector on the last I/O

board in the daisychain, as shown below:

Check the reading on the DVM. If the reading at the

Quantum™ has been adjusted properly, then this reading

can be no lower than +4.98 DC. If the voltage is less,

check all of the daisychain connections on the blue DC-I/O

harness. Ensure that all of its connectors are tight. If all

connections are good, then go back and start measuring

over again, this time beginning at the first board in the

daisychain. Continue checking the voltage at each

connection, until you locate the point at which the voltage

drop is excessive. This will usually indicate a connection

that is not being made properly, or the sockets within the

connector are weak. In either case, the DC-I/O wire

harness may need replacing.

Next, you will want to measure the +12 Vdc. Perform the

same steps as with the +5 Vdc measurement, with the

exception that you will not need to measure at the

Quantum™. Measure directly at the last connection. If the

voltage is low, ensure that there is not an excessive

voltage drop in the daisychain. If there is not excessive

loss, and the power supply is a Power One, then it can be

adjusted (refer to the Quantum™ Panel D.C. Power

Supply Layouts for adjustment location). If you have the

Condor, then the supply itself may need replaced.

The -12 Vdc may be measured the same as the other

voltages, however, this voltage is not adjustable on any

supply, so if the harness is not the culprit, the supply may

need to be replaced.

REPLACEMENT

Power One - If you have the Power One supply, and

it is found to be bad, or not capable of acceptable

adjustment, it will need replacing. Since the Power

One is no longer available from Frick

, an upgrade kit

can be ordered that will adapt the Condor supply to

the Power One mounting holes. Refer to the

Recommended Spare Parts list for the upgrade part

number. This upgrade kit will include the following

components:

• Tie wrap wire ties

• Adhesive backed tie wrap mounts

• Screws (6-32 x 3/8 flat head)

• Power supply (Condor)

• Mounting plate (adapts Condor to Power

One mounting holes)

• AC power cable harness (needed since the

Power One supply utilizes screw terminals,

and the Condor utilizes connectors)

• DC power cable harness (needed since the

Power One supply utilizes screw terminals,

and the Condor utilizes connectors)

Condor - If you have the Condor power supply, and it

is found to be bad, or not capable of acceptable

adjustment, it will need replacing. When ordering this

replacement, you will receive an upgrade kit. The

purpose of this kit is to allow for the upgrading of the

I/O DC power harness, at the same time as replacing

the power supply. Refer to the Recommended Spare

Parts list for the upgrade part number. This upgrade

kit will include the following components:

• Screws (6-32 x 3/8 flat head)

• Power supply (Condor)

• DC power cable harness (this is an improved

version of the previous power cable)

Loading...

Loading...