FRICK QUANTUM EVAPORATOR CONTROL PANEL S90-600 O

OPERATION Page 23

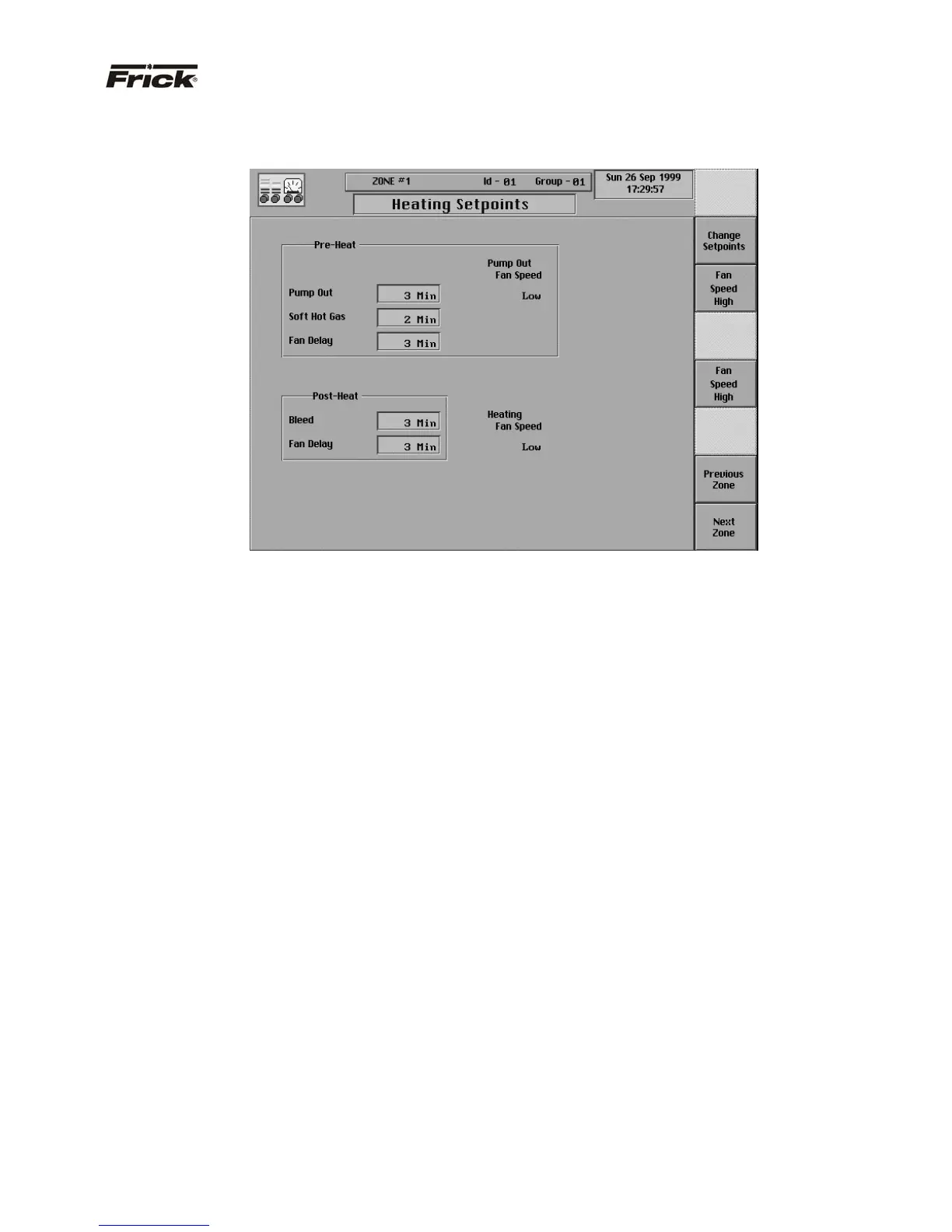

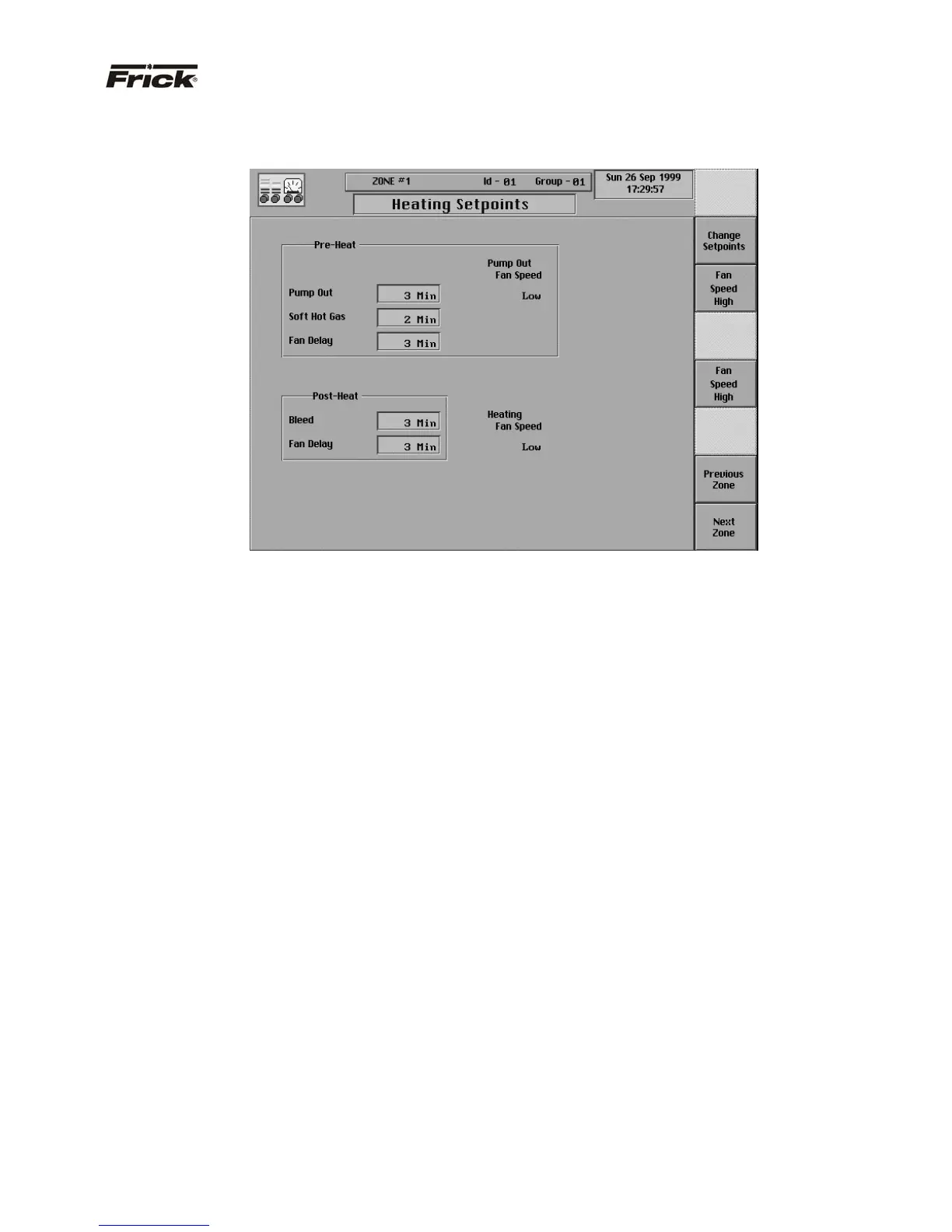

CONTROL SETUP -

“HEATING SETPOINTS” SCREEN

Heating is sometimes used to raise the temperature within

an area of a plant such as a loading dock. If the control

temperature is less than or equal to the “Heat On”

setpoint, control switches to using the heating setpoints.

The process of heating initiates with the “Pre-heat” stage.

“Pre-heat” is used to properly prepare for heating. “Pre-

heat” can consist of three steps: Pump Out, Soft Hot Gas,

and Fan Delay. If the control temperature does not equal

or exceed the “Heat Off” setpoint, then heating will occur

after “Pre-heat” completes. During the heating stage, the

hot gas valve is open and fans are running. If the control

temperature equals or exceeds the “Heat Off” setpoint

after “Pre-Heat” has completed, then control stops the

heating and proceeds to the “Post-heat” stage. The “Post-

heat” stage is used to properly exit from heating. “Post-

heat” can consist of two steps: Bleed, and Fan Delay.

Each step has an operator adjustable time setpoint.

Pre-Heat:

· During “Pump Out” the liquid output is closed

(de-energized) while the suction valve and the

fan output remain opened (energized) to remove

and evaporate as much as possible of the

remaining liquid refrigerant.

· During “Soft Hot Gas” the soft hot gas valve is

opened, the other valves are closed, and the fans

are stopped. The soft hot gas valve is used to

slowly turn on hot gas and lower the pressure

differential that occurs when going from cooling

to heating. – (enhanced unit only)

• During “Fan Delay” the hot gas valve is opened,

the other valves are closed, and the fans are

stopped. The fan remains off for the set amount

of time. This step allows high pressure/high

temperature gas to enter the evaporator coil and

melt the frost build up from the evaporator coils

clearing the coil for good airflow. The hot gas

valve remains opened until the temperature rises

to or above the hot gas off temperature setpoint

Post-Heat:

· During “Bleed” the hot gas solenoid output is de-

energized, and the bleed solenoid output is

energized for the set amount of time. This bleed

step is usually energized for a few minutes to

allow the hot gas trapped in the evaporator coil to

slowly release from the tubing so as not to too

quickly over pressurize the suction piping line

and vessel.

· During “Fan Delay” the bleed solenoid is de-

energized and the liquid and suction solenoid

outputs are energized again allowing the liquid

refrigerant to cycle through the evaporator coil

thus cooling the evaporator to an operating

temperature. This step usually lasts for just a few

minutes and is used mainly to frost the small

amount of water left on the unit so as to not blow

water over product when the fan is restarted.

· After “Fan Delay”, the fan output is energized

again to provide air movement across the

evaporator coil to re-initiate the cooling process.

Note: If a zone does not have a Bleed solenoid, the

bleed step of the heating cycle can be used to close

the Hot Gas solenoid valve and use the bleed time for

cooling of the hot gas trapped in the evaporator.

Loading...

Loading...