Operation manual P328S

© 2018 FROMM Holding AG 23

All rights reserved. Reproduction and duplication - also in extracts - are not permitted.

8Strapping

The following sections describe a strapping procedure in the manual operation mode (CLASSIC work menu).

See 7.10.1 CLASSIC Work Menu, MAN Operation Mode (Manual)

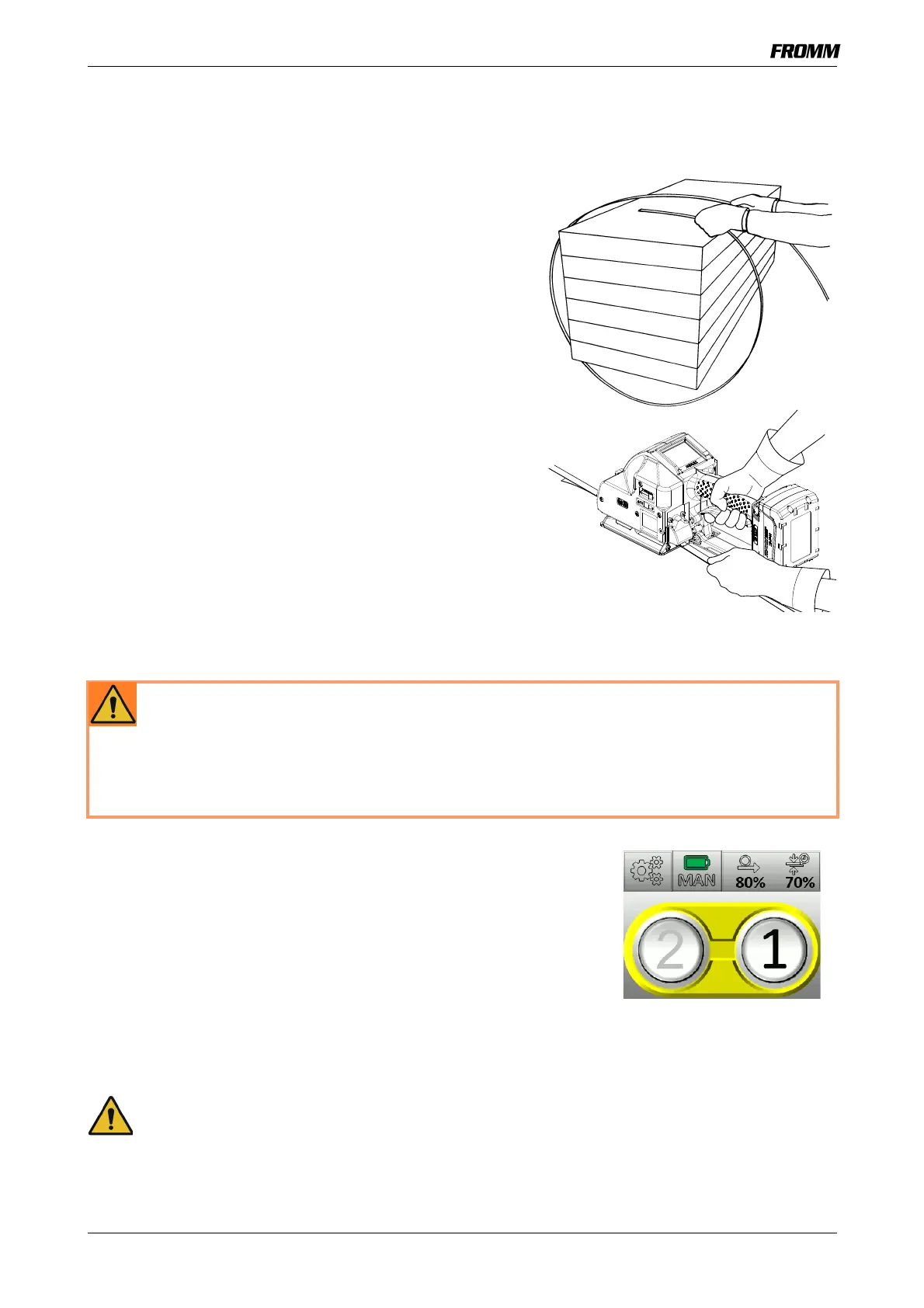

8.1 Feeding the strap around the package

• The strapping is fed around the package as illustrated.

The plastic strap which will be welded must be free from

oil, grease and other dirt.

Dirty plastic straps can't be welded correct!

8.2 Inserting the strap

• Pull up the handle lever firmly with your right hand.

• Insert the two straps well aligned on each other into the strap

guide using your left hand.

The lower strap end must slightly protrude the end of the base

plate.

• Release the handle lever.

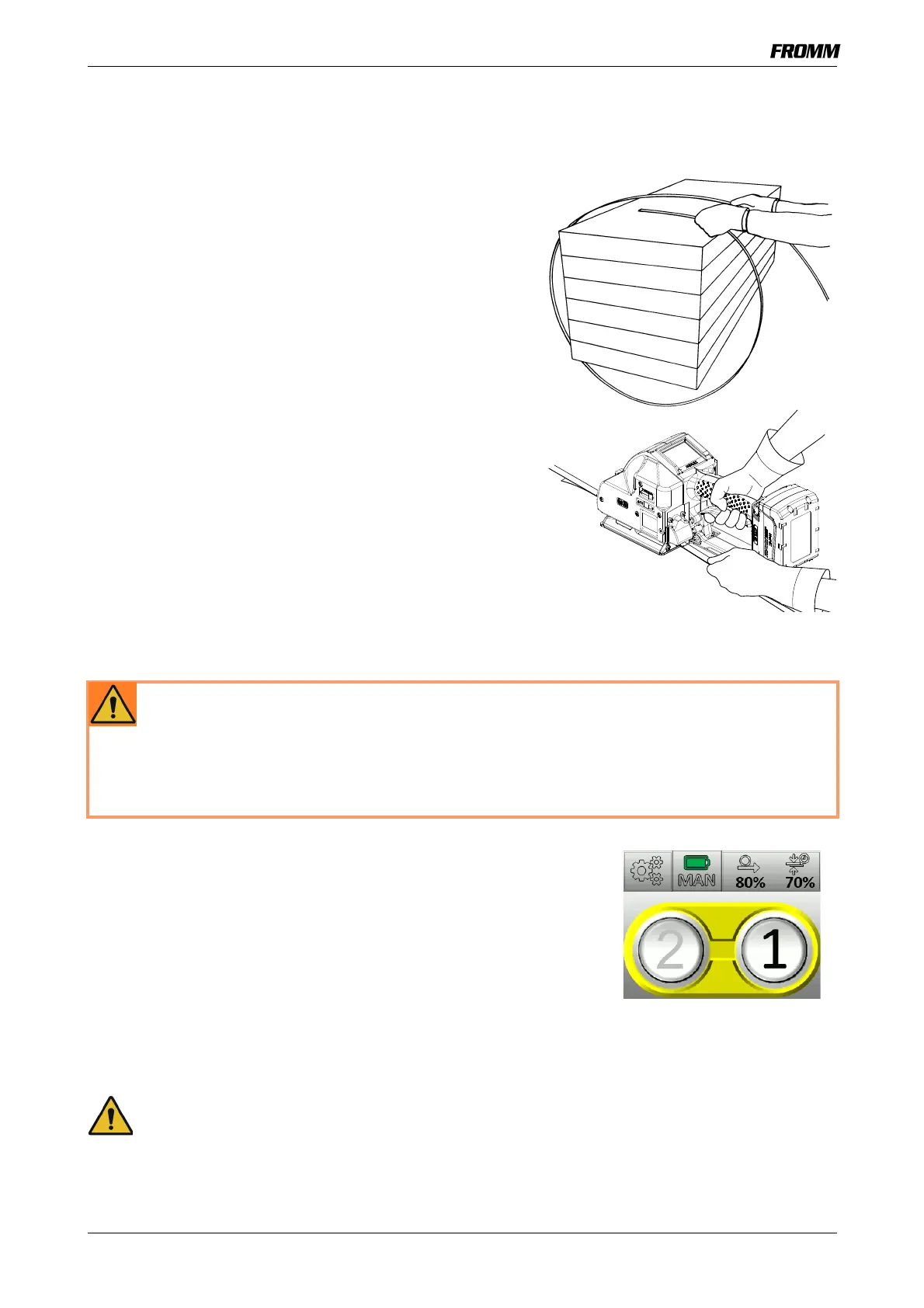

8.3 Tensioning the strap

• Press the tension key until the desired tension is reached.

See 7.2 Set Strap Tension and Welding Time

The tension can be interrupted by releasing the tension key and

started again.

Only for the automatic operation mode:

Reduce Risks / Prevent Improper Strapping

The tension can be interrupted by tapping the tension key again or by lifting up the lever.

WARNING Hazard of injury due to spring back strap and falling down objects. Do not adjust

the tensioning force too high. If the tension force is adjusted to high, the strap will break during

tensioning.

Hazard of injury due to pinching, cutting and shearing.

During tensioning of the strap there must not be any hands or body parts between strap loop and

strapped object. Make sure that no other persons are present in the area endangered by tensioning

the strap.

NOTICE Tensioning and welding of an already welded strapping can cause massive

disorders and damages of the tool. After welding and cooling the tool has to be removed from the

strapping before a new strapping cycle is started.

Loading...

Loading...