What to do if my Fronius FlexTrack 45 Welding System shows 'err2'?

- TtimothyrodgersAug 5, 2025

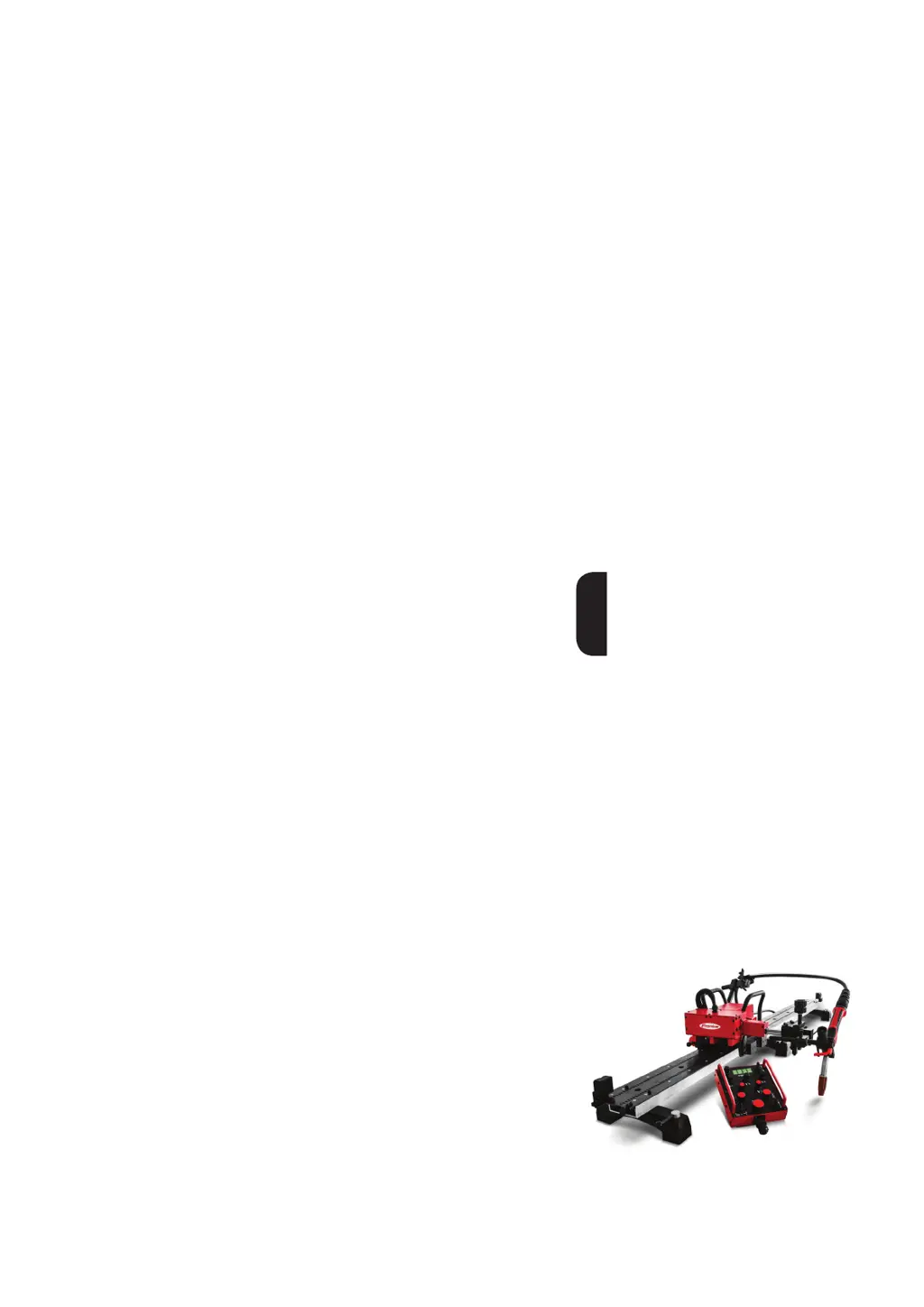

If the Fronius Welding System displays 'err2', it indicates a connection problem. You should check all connections and tighten them if necessary. If the control lines are damaged, they should be replaced.