VMP-IOMM-2018-2

Fulton Ltd

Page 11

INSTALLATION - 2

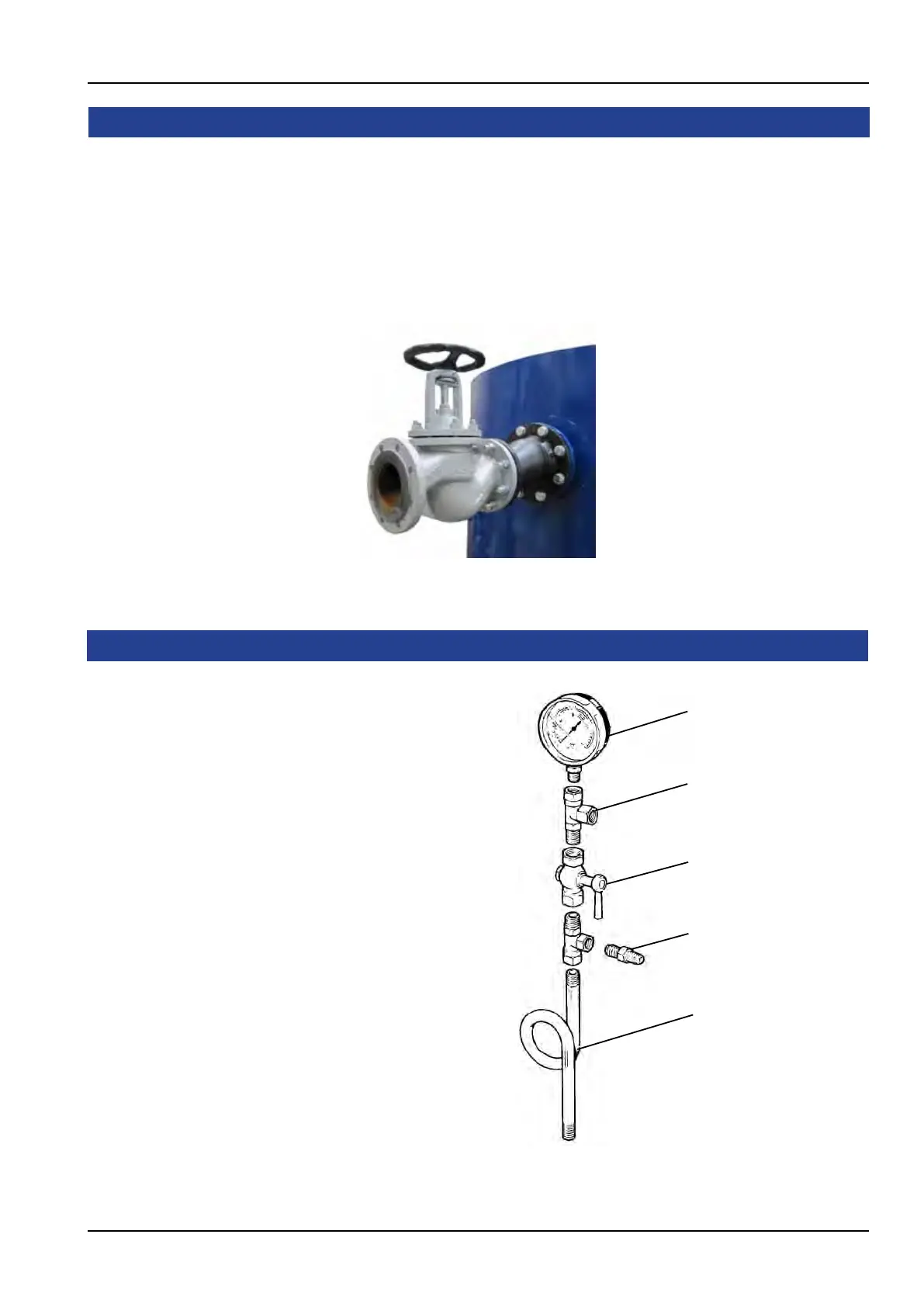

2.4.5 STEAM PRESSURE GAUGE

The steam pressure gauge assembly

should be assembled in accordance

with Figure. 8 using a suitable sealant

on all joints.

The gauge should be facing front

towards the electrical control box and/

or the operator of the boiler.

Screw the assembly into the top of

the water level gauge (sight glass)

and connect the copper tube from

the pressure controller located on the

side of the control box to the nipple

provided on the assembly.

Test Point

Steam Pressure Gauge

Steam Cock

Syphon

Plugged

Figure. 8 - Steam Pressure Gauge

Distribution pipework should be run from the main steam valve on the boiler to the steam delivery

point(s). Care should be taken to ensure that adequate condensate drainage and expansion

facilities are provided within the pipework run(s).

To prevent excessive loads being imposed on the main steam isolating valve, the pipework

shouldbesecuredneartheboiler,ensuringadequateexibilityexistsinthepipeworkbetweenthe

steam valve and the securing point, to minimise any loads imposed on the valve.

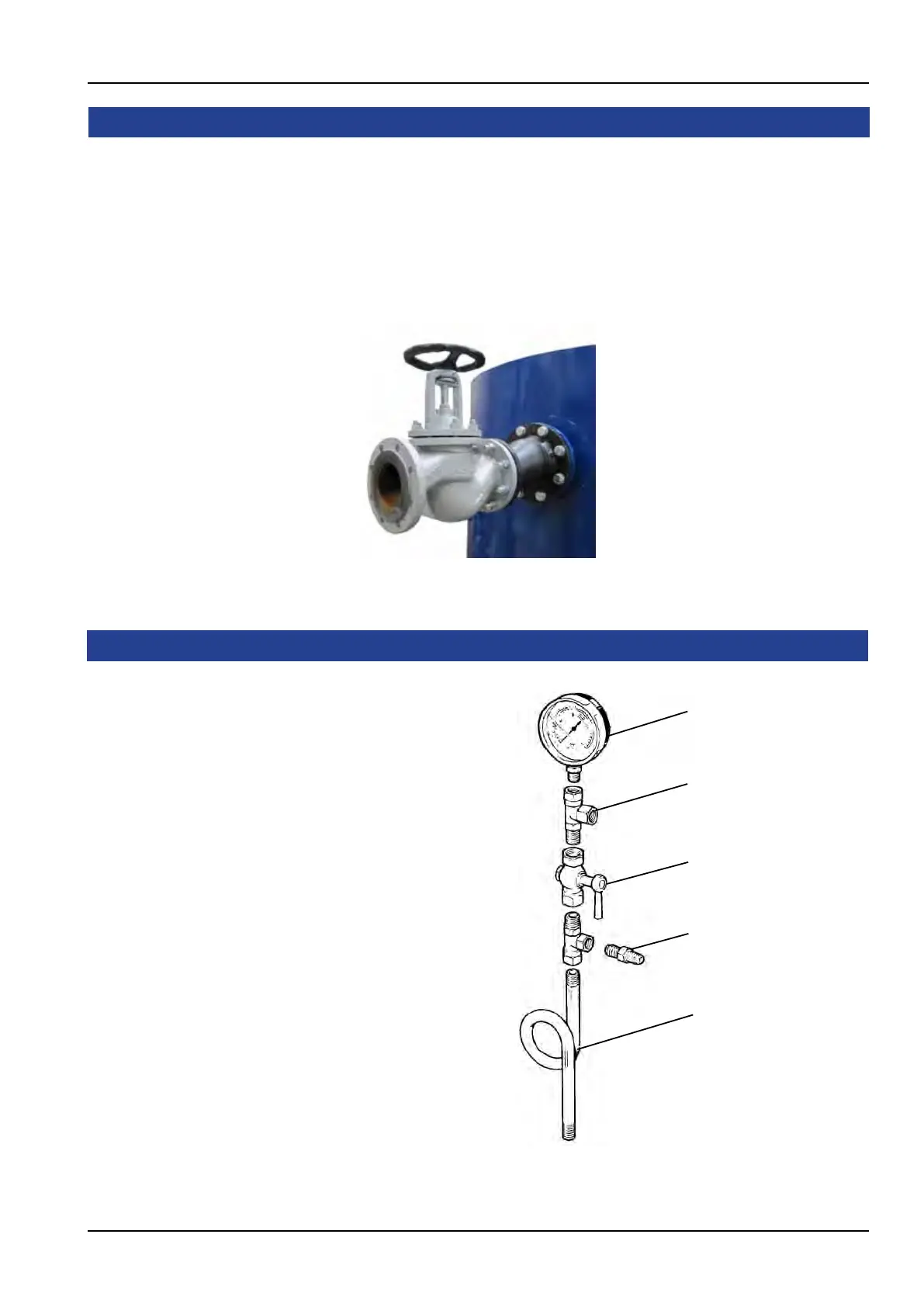

2.4.4 MAIN STEAM VALVE

Figure. 7 - Main Steam Valve

Loading...

Loading...