VMP-IOMM-2018-2

Fulton Ltd

Page 57

MAINTENANCE - 5

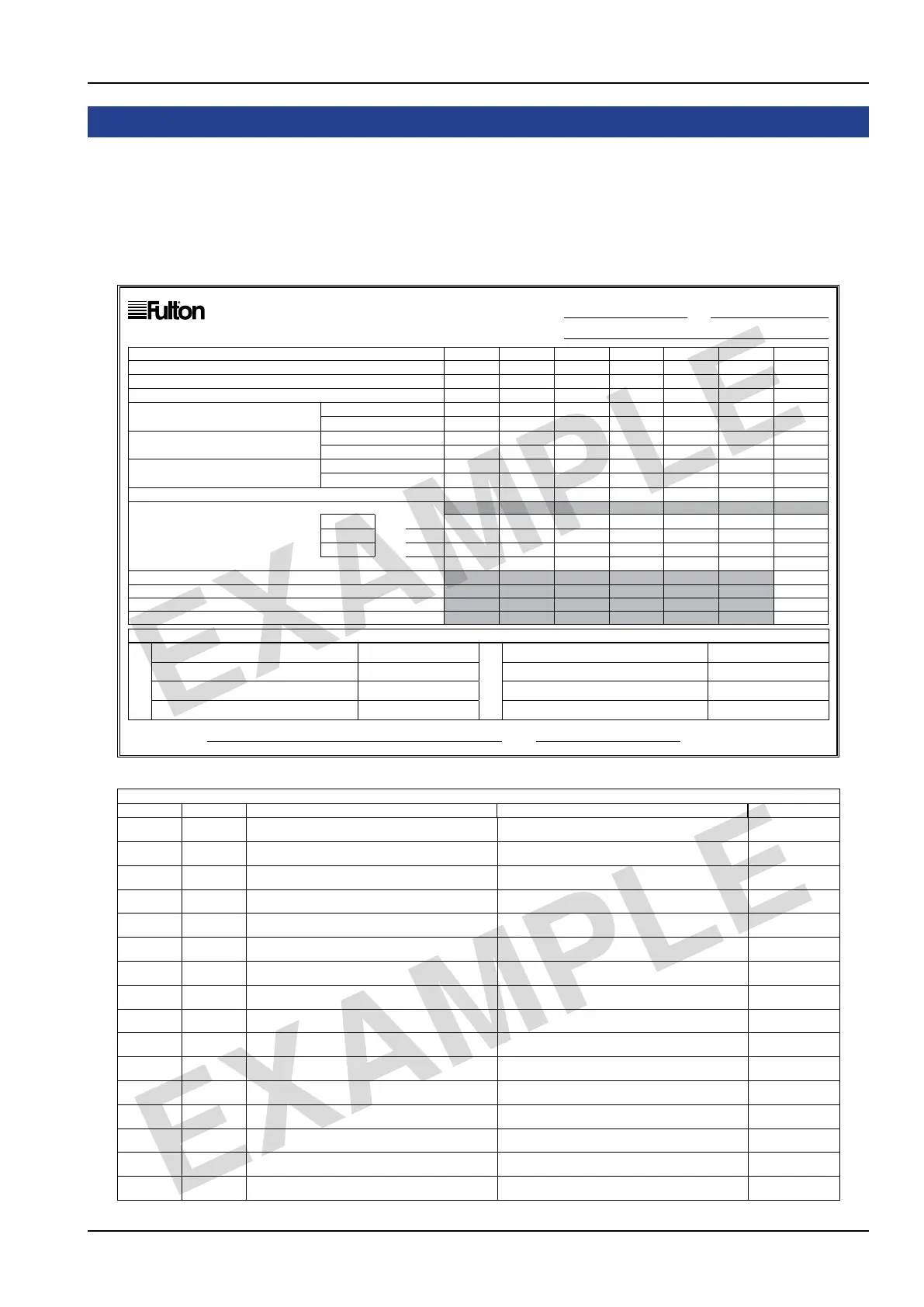

DAILY TESTS 1 2 3 4 5 6 7

Date

1.

V

isual Inspectionofpipework,ttingsandhandholesforsignsofleakage. Y - N Y - N Y - N Y - N Y - N Y - N Y - N

2.

Low W

ater Level Check - low water indicator illuminate, alarm sound and burner cuts-out. Y - N Y - N Y - N Y - N Y - N Y - N Y - N

3.

Blowdown, Boiler

Duration seconds.

T

est Time.

4.

Blowdown, W

ater Bottle

Duration seconds.

Test Time.

5.

Blowdown, W

ater Level Gauge

Duration seconds.

Test Time.

6.

Pressure gauge

reading for blowdown tests.

Boiler water and water treatment values must be within known tolerances of the datum.

7.

Boiler W

ater.

datum value. TDS. reading

datum value. PH reading

8.

Oxygen Scavenger Concentration datum value. reading

9.

Brine level correct Y -

N Y - N Y - N Y - N Y - N Y - N Y - N

WEEKLY TESTS 7+

10. Flame Sensor Test Y - N

11.

Feedwater Pump T

est - Feedwater pump, start/stop Y - N

12.

Safety valve outlet pipe

to safe blowdown point and free of damage Y - N

Test results and actions taken

Day 1. sig. Day 5. sig.

2. sig. 6. sig.

3. sig. 7. sig.

4. sig. 7+. sig.

Log examined by: Date:

Vertical Steam Boiler - Daily and Weekly Tests

Model:

Fuel:

Boiler Number:

MAINTENANCE LOG

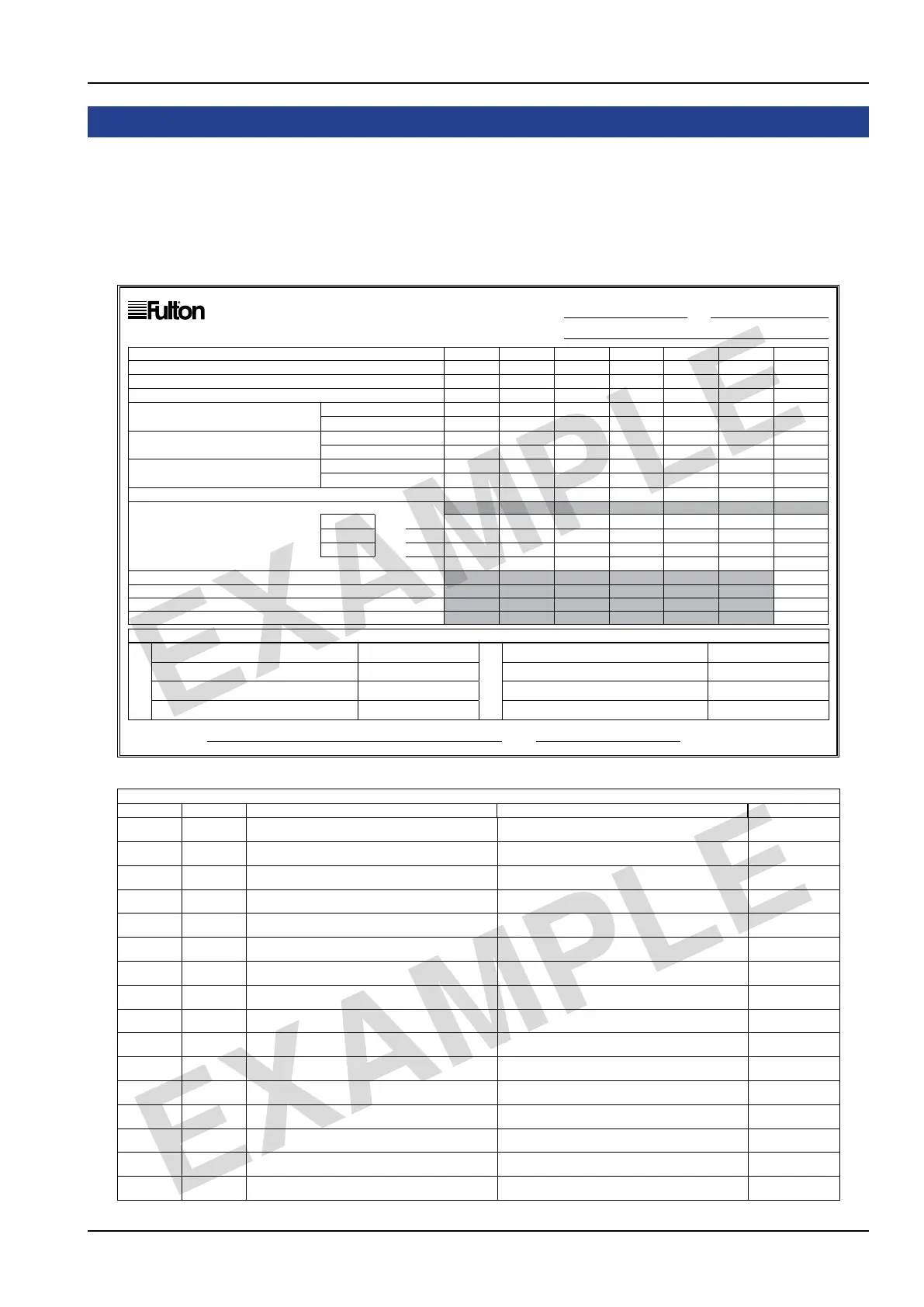

Date Time Operation Performed Remarks Operators Initials

5.9 MAINTENANCE RECORD KEEPING

Boiler log sheets should be completed on a regular basis, this provides invaluable information in

the subsequent investigation of the boiler history. Maintenance log sheets can be found in the

Fulton boiler Log Books provided by Fulton.

To Purchase a Fulton Boiler Log Book, please contact training@fulton.co.uk.

Loading...

Loading...