VMP-IOMM-2018-2

Fulton Ltd

Page 50

MAINTENANCE - 5

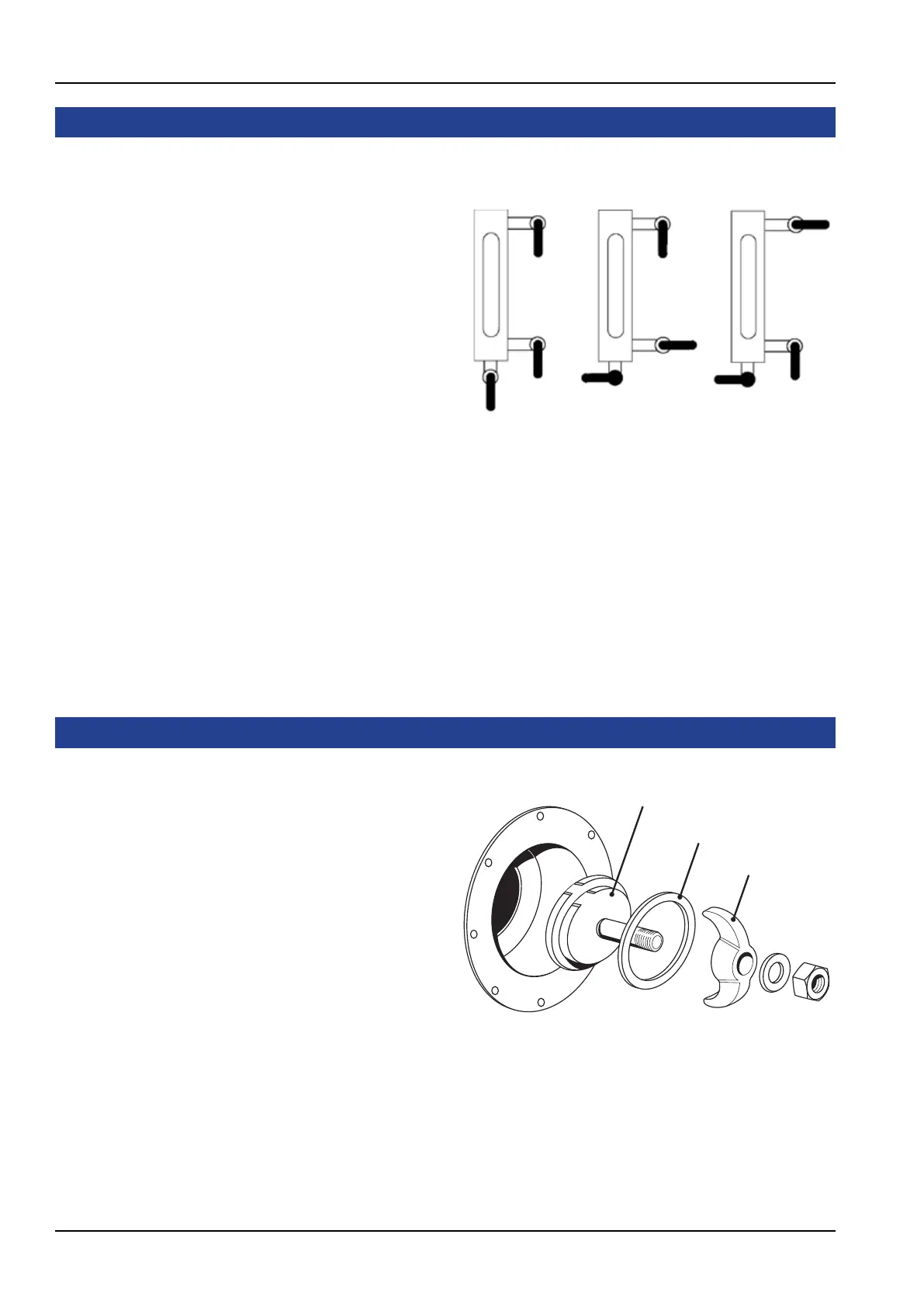

5.5.3 WATER LEVEL GAUGE (SIGHT GLASS) BLOWDOWN

Blowdown the water level gauge (sight

glass) set 1.

1. Open the water level gauge glass

blowdown valve A

2. Close (for approx. 3 seconds) the

top gauge valve B

3. Open valve B

4. Close (for approx. 3 seconds) the

bottom gauge valve C

5. Open valve C

6. Close valve A

Repeat for gauge set 2

On completion of the blowdown

procedure ensure that all isolation

valves are OPEN and all blowdown

valves are CLOSED.

Note: Where a boiler is operating continuously at

steam pressure, advice should be taken from Fulton

Ltd as to the appropriate blowdown procedure.

POSITION

STEAM

BLOWDOWN

WATER

BLOWDOWN

A

A

A

B

BB

C

C

C

Figure. 26 - Water Level Gauge Operating Positions

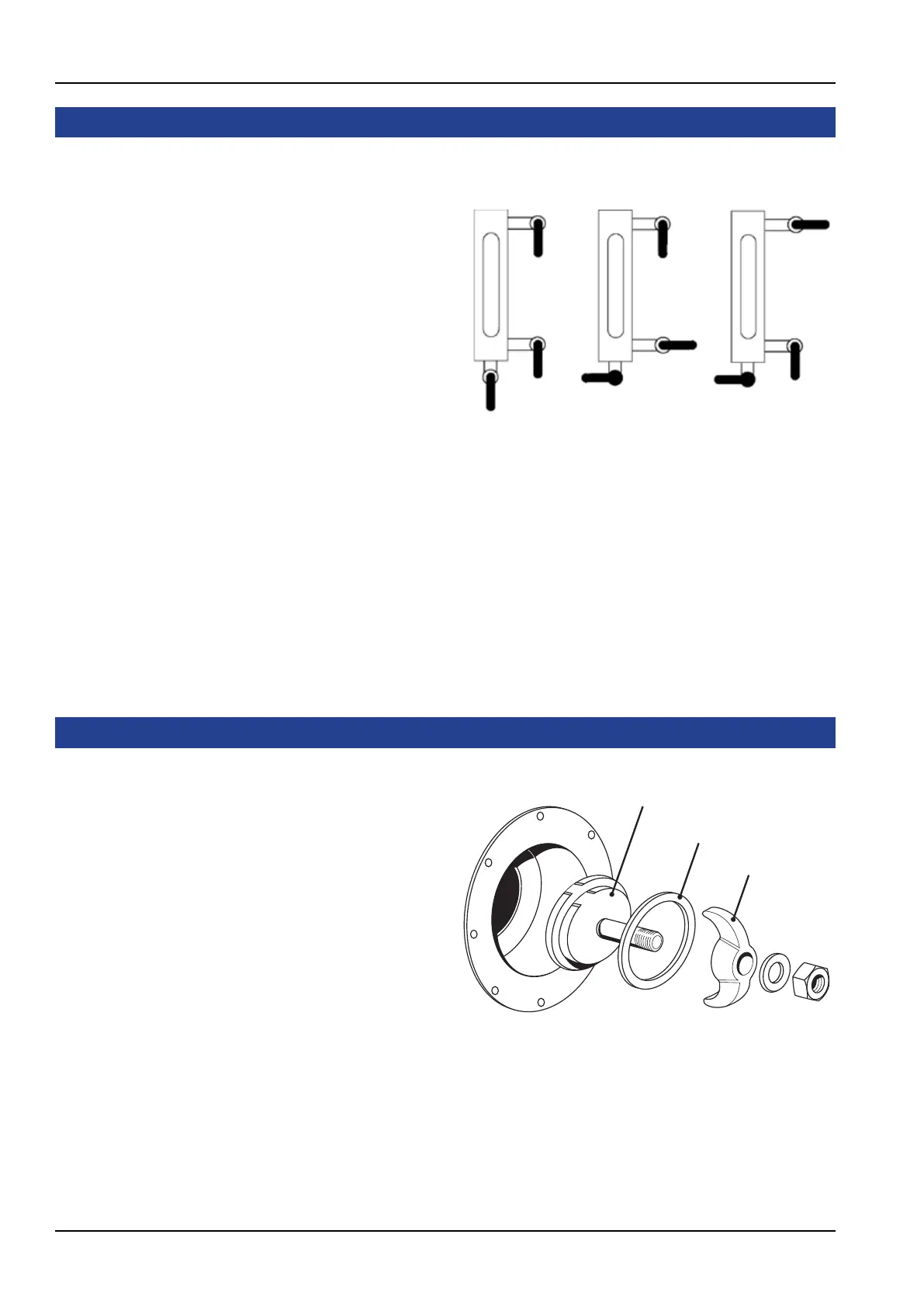

5.6 BOILER INTERNAL INSPECTION

The lower hand hole doors should be

removed after one month of operation

and the interior of the boiler thoroughly

examined. If scale or sludge build-up is

observed, it should be removed and the

water treatment supplier advised.

Newgasketsmustbettedeverytime

a hand hole door is removed (see

Section 5.7 - Fitting New Gaskets To

Boiler Inspection Holes).

Subsequent interior examinations

should be carried out on a regular

basis until satisfactory conditions are

observed. Thereafter, inspections

should be carried out at three monthly

intervals.

Hand Hole Cover Plate

Gasket

Crab

Figure. 27 - Hand Hole

Loading...

Loading...