VMP-IOMM-2018-2

Fulton Ltd

Page 69

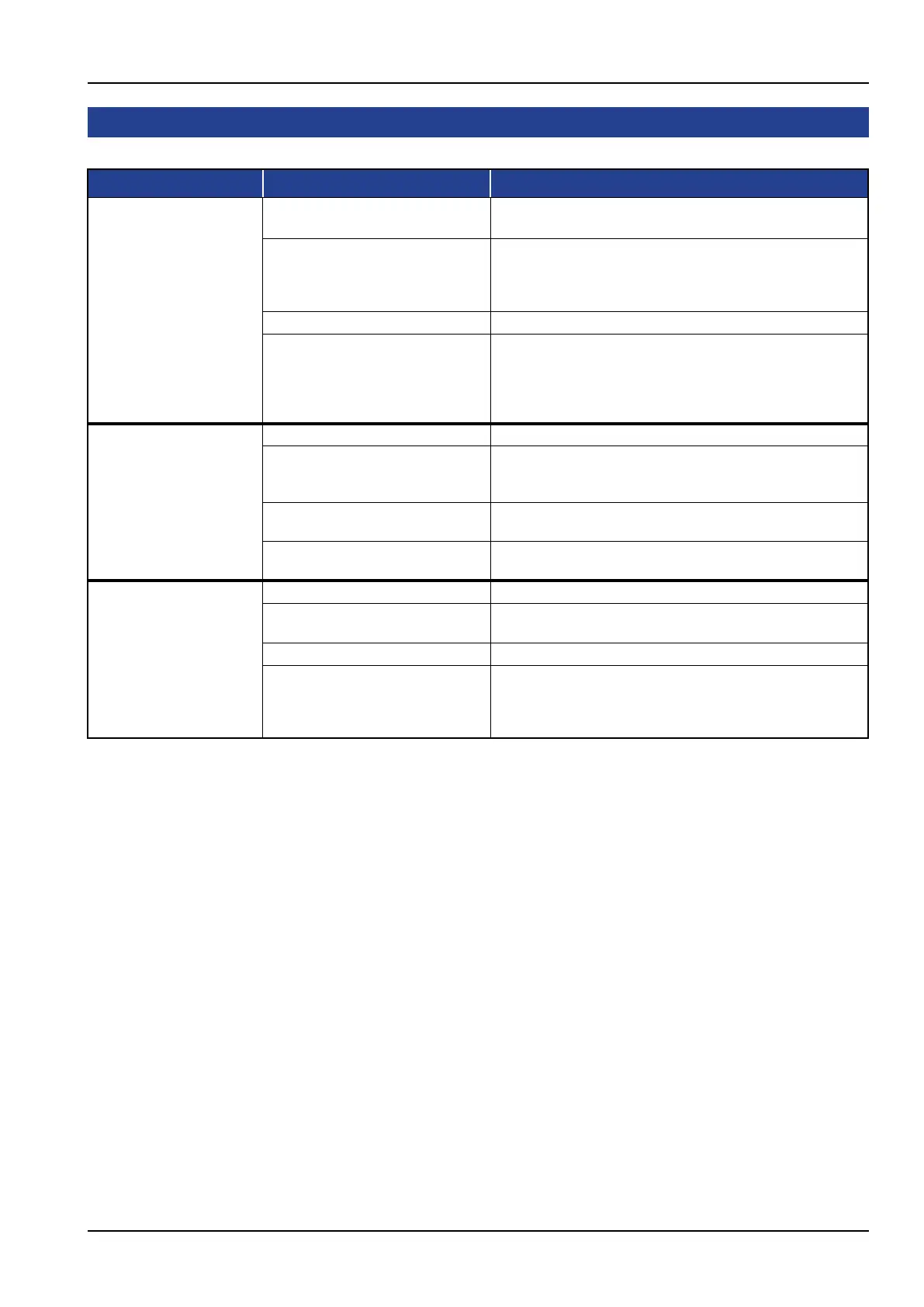

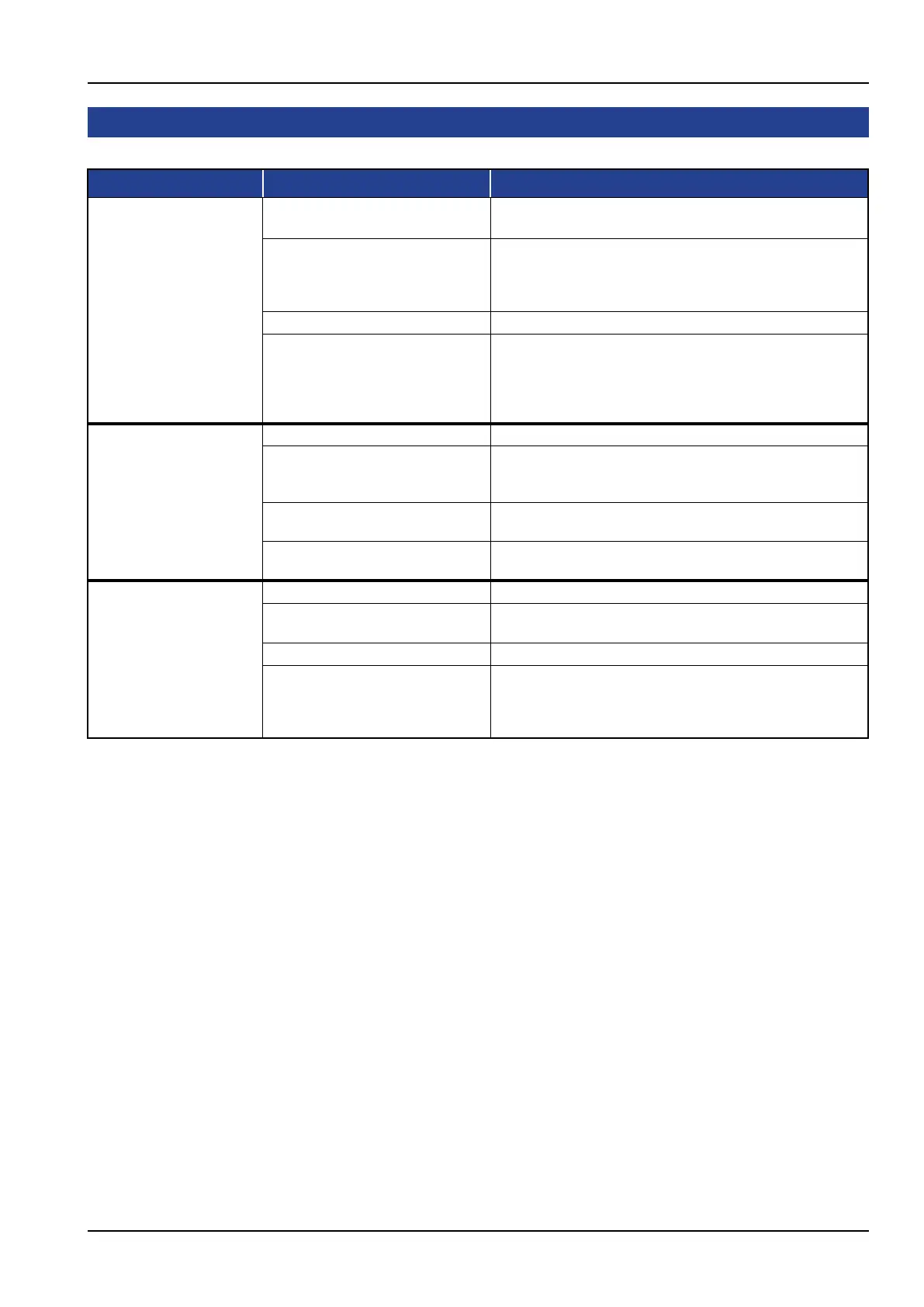

TROUBLESHOOTING - 6

6.3 TROUBLESHOOTING FEEDWATER PUMP

Problem Cause Remedy

8. Noise. 1. Cavitation occurs in the pump. Check the suction conditions.

2. Pump does not rotate freely

(frictional resistance because

of incorrect pump shaft

position.

Adjust the pump shaft.

3. Frequency converter operation. See Grundfos manual.

4. Boiler feedwater non-return

valve letting water passed

the valve seat, (normally

accompanied by banging in the

feedwater tank).

Check and clean boiler feedwater non-return valve, ensure

it is seating and not allowing water passed.

9. Water pump runs

intermittently

1. Scale on probes. Check and clean probes, replace as necessary.

2. Faulty pump contactor Check the contactor has power. Check the contactor is

pulling in.

Replace if necessary.

3. Faulty pump motor. Check the pump has power.

If the pump has power but is not running, replace it.

4. Faulty Level Control Relay Check the relay has power and is secure on it’s base.

Replace if faulty.

10. 1. Pump does not shut off. Dirty probes. Clean or replace as necessary.

2. Relay failed. Ensure the relay is secure on its base.

If so replace the water level relay.

3. Earth connection. Clean and tighten as required.

4. Vacuum created with boiler

off.

As the boiler cools, it pulls water from the system piping.

To prevent this, add a check valve on the steam gauge

assembly piping, which closes under

pressure and opens under vacuum.

Loading...

Loading...