VMP-IOMM-2018-2

Fulton Ltd

Page 75

TROUBLESHOOTING - 6

242/254

Building Technologies Division Basic documentation LMV26... CC1P7547en

30 Error code list 20.04.2016

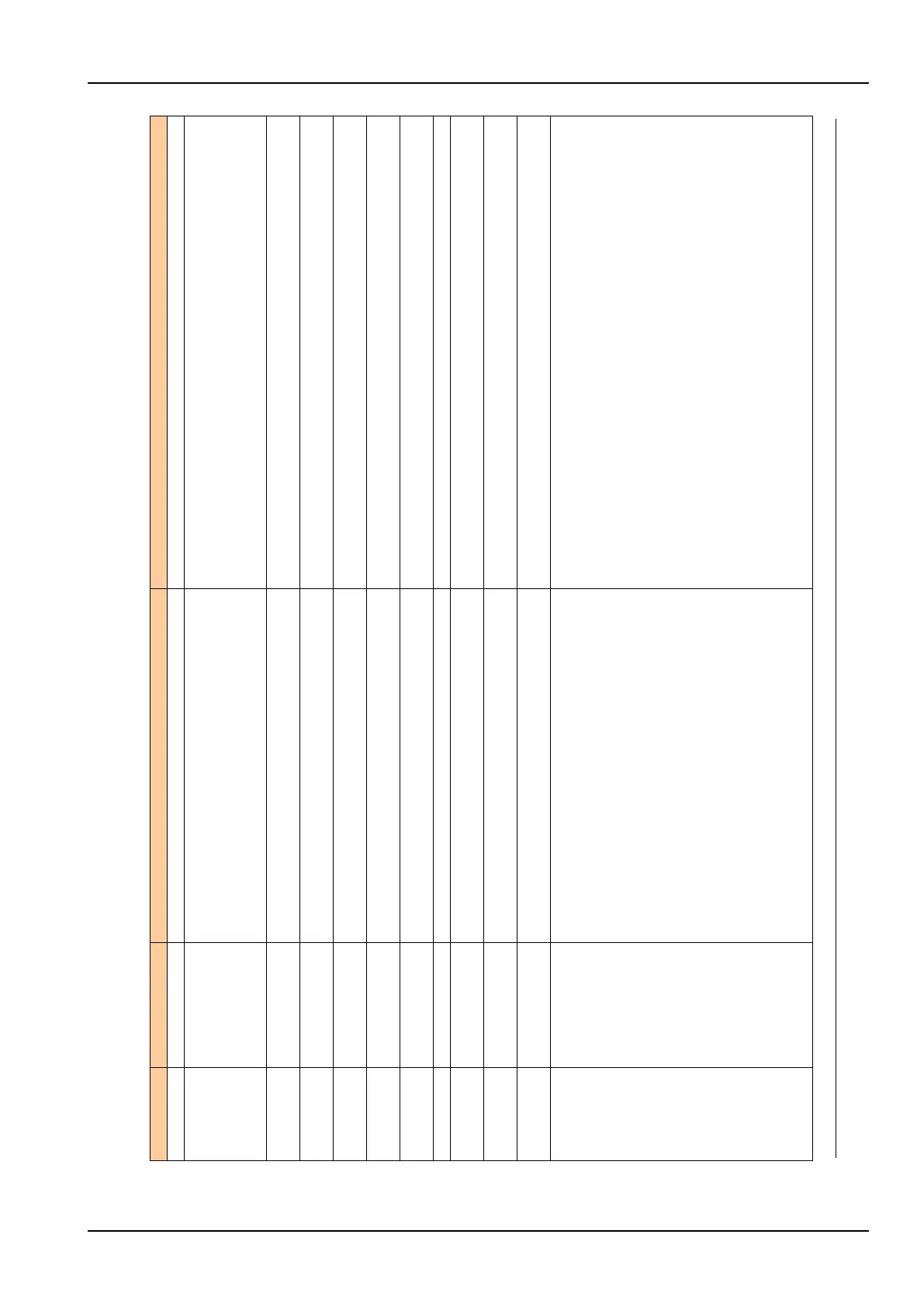

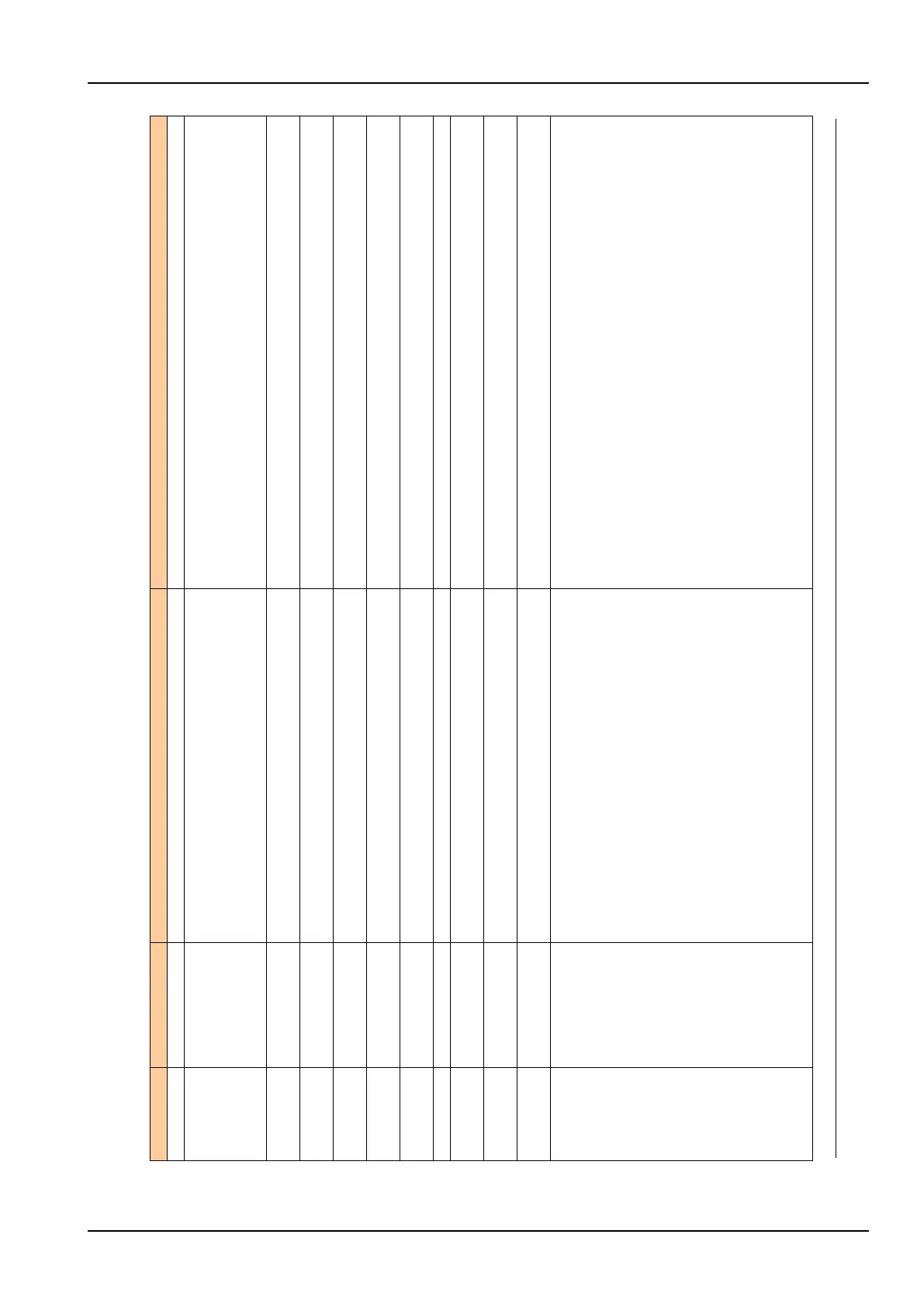

Error code Diagnostic code Meaning for the LMV26... system Remedy

21 Safety loop / burner flange open

Safety loop or burner flange is open repeat standardization with safety loop closed

22 Air actuator not referenced

Air actuator has not been referenced or has lost its referencing.

1. Check if the reference position can be approached.

2. Check if actuators have been mixed up.

3. If error only occurs after the start of standardization, the actuator might be overloaded and

cannot reach its destination.

23 VSD deactivated

Standardization was started with VSD deactivated

activate the VSD and repeat standardization

24 No valid operating mode

Standardization was started without valid operating mode

activate valid operating mode and repeat standardization

25 Pneumatic air-fuel ratio control

Standardization was started with pneumatic air-fuel ratio control

standardization with pneumatic air-fuel ratio control not possible

128 Running command with no preceding standardization

VSD is controlled but not standardized

make standardization

255 No standardized speed available

Motor turns but is not standardized

make standardization

83 # Speed error VSD Required speed has not been reached

Bit 0

Valency 1

Lower control range limitation of control

Speed has not been reached because control range limitation has become active

for measures, refer to error code 80

Bit 1

Valency 2...3

Upper control range limitation of control

Speed has not been reached because control range limitation has become active

for measures, refer to error code 80

Bit 2

Valency 4...7

Interruption via disturbance pulses

Speed has not been reached due to too much electromagnetic interference on the sensor line

for measures, refer to error code 81

Bit 3

Valency

8

Curve too steep in terms of ramp speed

Check speed differential between the curvepoints and the modulating operating ramp setting

(parameter 544).

1. Modulating operating ramp 32 seconds

Curve slope max. 10% for LMV2 ramp of 20 seconds (20% for 10 seconds or 40% for 5

seconds)

2. Modulating operating ramp 48 seconds

Curve slope max. 10% for LMV2 ramp of 30 seconds (20% for 15 seconds or 30% for 10

seconds)

3. Modulating operating ramp 64 seconds

Curve slope max. 10% for LMV2 ramp of 40 seconds (20% for 20 seconds or 40% for 10

seconds)

→ Between the ignition point (P0) and the low-fire point (P1), the speed change in

modulating

mode may be a maximum of 40%, independent of the LMV2 ramp.

2. The setting of the VSD ramp must be about 20% faster than the ramps in the basic unit

(parameters 522, 523).

Loading...

Loading...