3–2 D485 MODBUS TO DEVICENET CONVERTER – USER GUIDE

DATA EXCHANGE

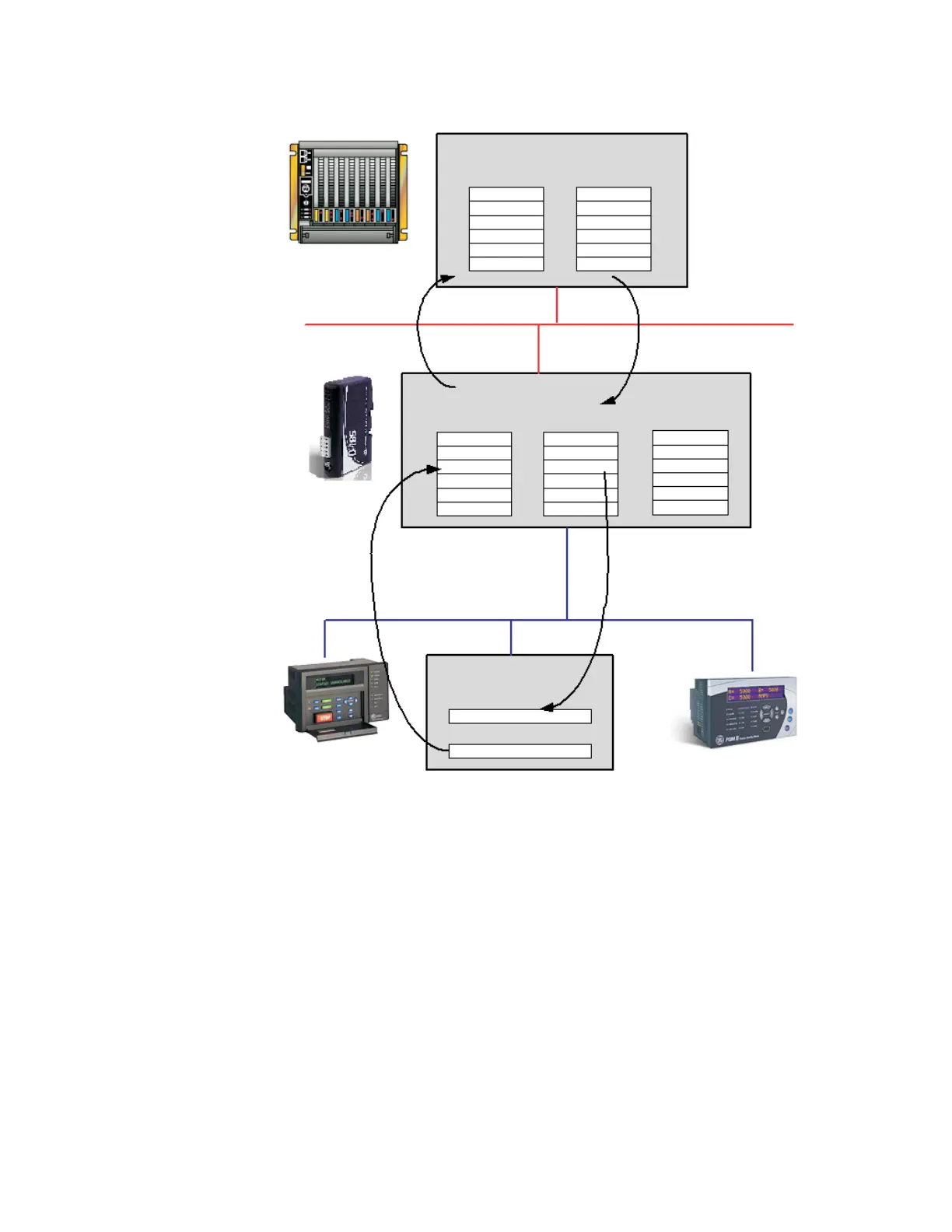

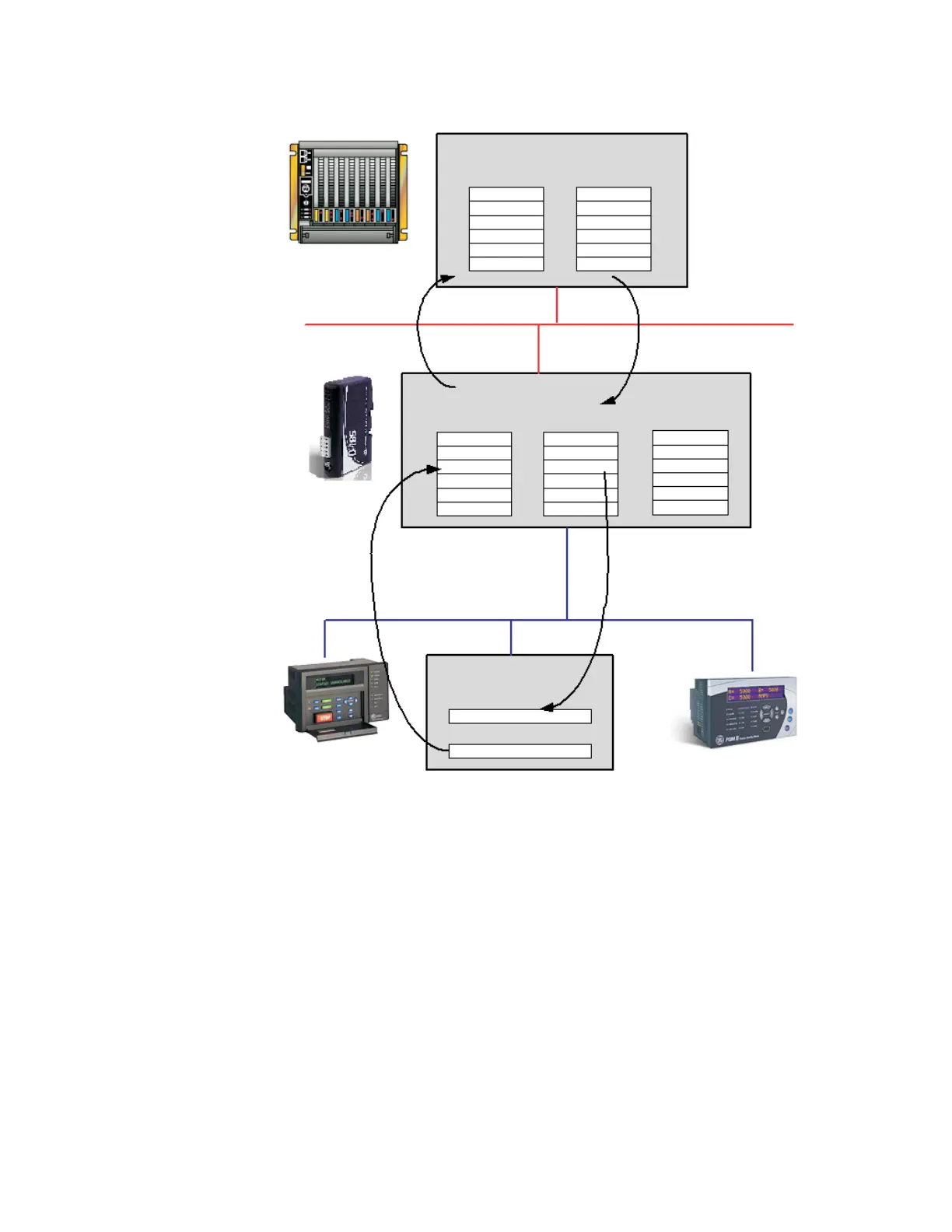

Figure 3-1: Data exchange overview

INTERNAL MEMORY

BUFFER STRUCTURE

The internal memory buffer can be seen as a memory space with three different types of

data; input data, output data and general data.

• Input data: This is data that should be sent to the fieldbus. The D485 can handle up to

512 bytes of input data.

• Output data: this is data recieved from the fieldbus. The D485 can handle up to 512

bytes of output data.

• General data: This data cannot be accessed from the fieldbus, and is used for

transfers between nodes on the sub-network, or as a general “scratch pad” for data.

The D485 can handle up to 1024 bytes of general data.

The PLC exchanges data

via the DeviceNet network

between its internal input

area and the input area

of the D485

DeviceNet network

The PLC exchanges data

via the network

between its internal output

area and the output area

of the D485

DeviceNet

The data in the input area of

the D485 contains data received

from nodes on the Modbus

sub-network (sent in to the D485

from the sub-network)

The data in the output area of the

D485 contains data received from

In this case, it is the CT PRIMARY

setting of the PQMII meter

(sent out from the D485 to the sub-network).

DeviceNet

0x0000 0x0200 0x0400

Input data area Output data area General data area

Modbus sub-network

Current Ia CT PRIMARY

Internal memory buffer

of the D485

PLC memory

I/O inputs

I/O outputs

Current Ia

CT PRIMARY

Modbus slave (e.g. PQMII)

CT PRIMARY setting

Current Ia actual value

Loading...

Loading...