5-206 M60 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

GROUPED ELEMENTS CHAPTER 5: SETTINGS

5

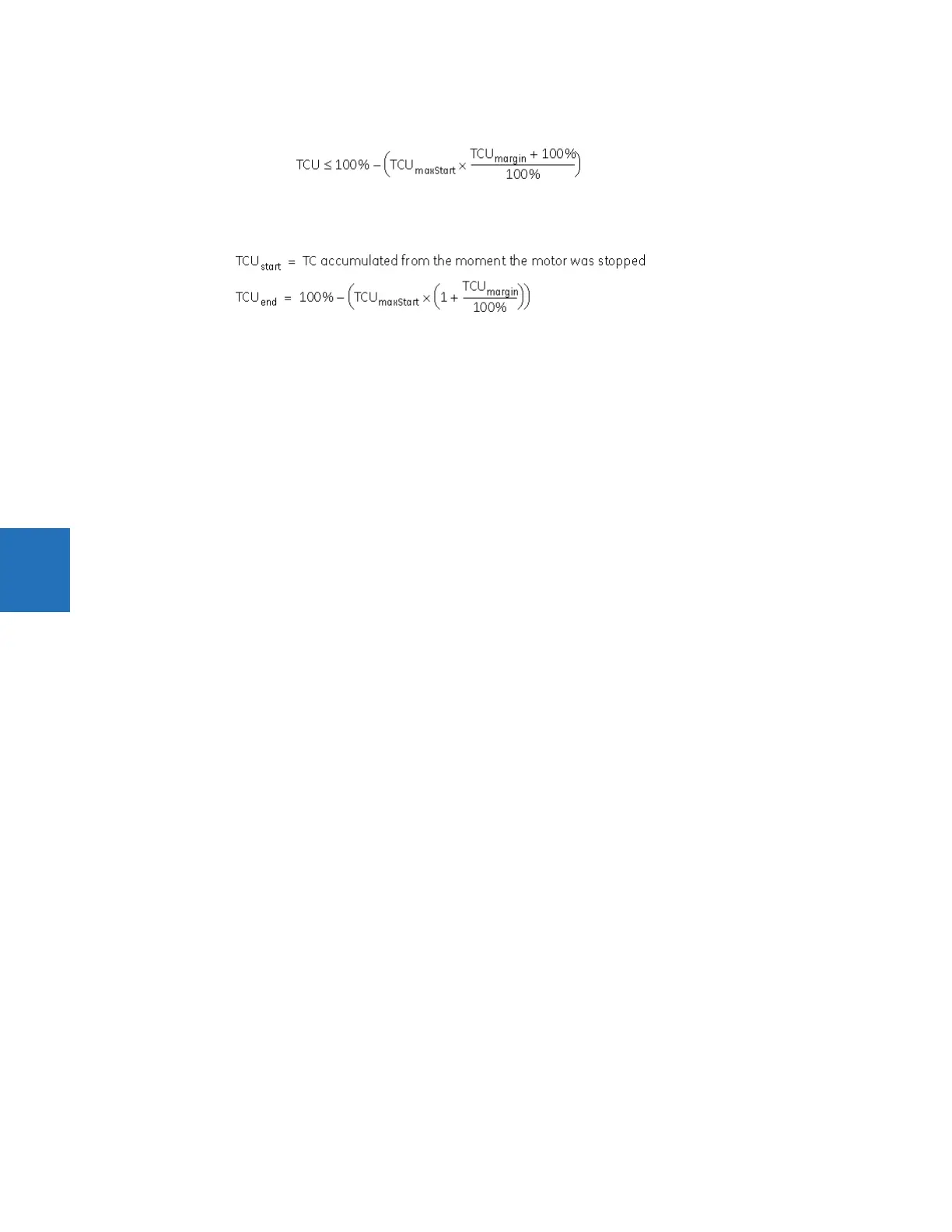

In this case, the MOTOR START INHIBIT operand resets when TCU decays to the level satisfying the following equation.

Eq. 5-22

To calculate the thermal lockout time for the case when the MOTOR START INHIBIT MARGIN setting is greater than “0,” the

following TCU values are applied.

Eq. 5-23

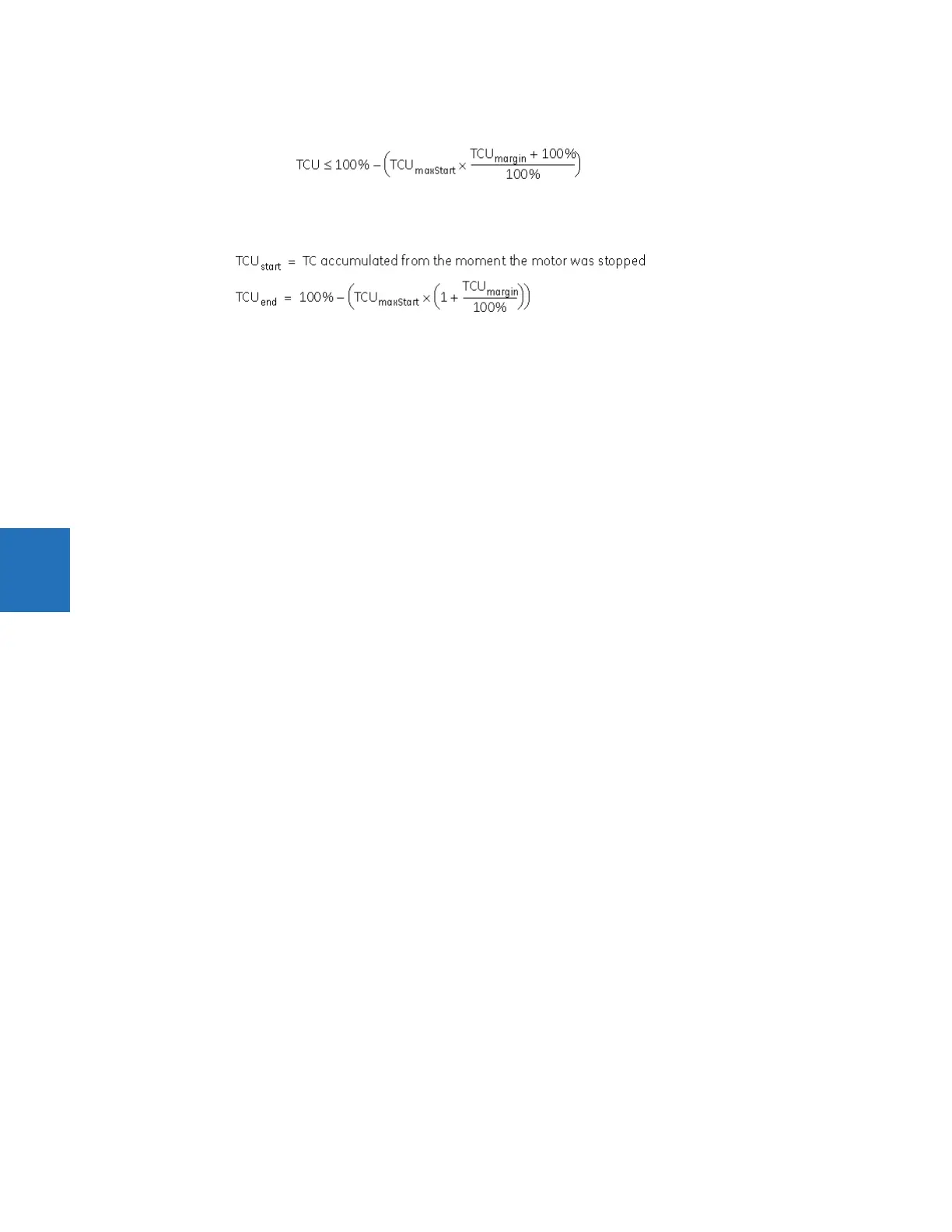

If MOTOR START INHIBIT MARGIN is greater than “0,” but the relay does not contain records for five successful starts, then the

MOTOR START INHIBIT operand can be asserted again either when the motor is tripped by thermal protection (TCU = 100%) or

tripped/stopped by any other reason (TC

accumulated

< 100%). However, operand reset is evaluated based on 15% level of

thermal capacity. To calculate the thermal lockout time in this case, the following values of TCU are applied to the previous

equation: TCU

start

= thermal capacity accumulated from the moment the motor was stopped, and TCU

end

= 15%.

VOLTAGE DEPENDENT FUNCTION — If the motor is called upon to drive a high inertia load, it is quite possible and acceptable

for the acceleration time to exceed the safe stall time (keeping in mind that a locked rotor condition is different than an

acceleration condition). The voltage dependent overload curve feature is tailored to protect these types of motors. This

curve is composed of the three characteristic of thermal limit curve shapes as determined by the stall or locked rotor

condition, acceleration, and running overload. The following figure presents the typical thermal limit curve for high inertia

application.

Loading...

Loading...