5-218 M60 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

GROUPED ELEMENTS CHAPTER 5: SETTINGS

5

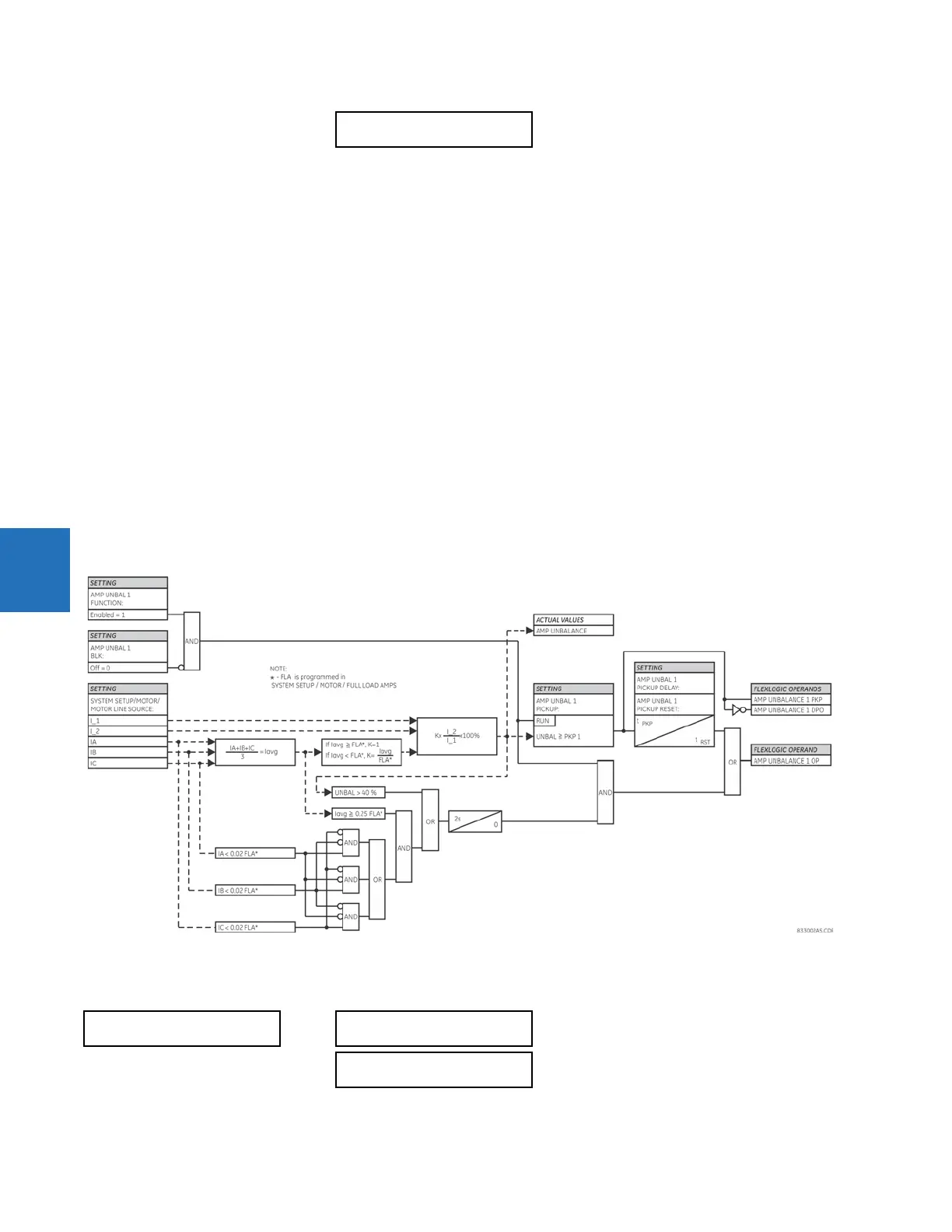

This element receives current inputs from the source selected by the SETTINGS SYSTEM SETUP MOTOR MOTOR

LINE SOURCE

setting. Generally, this element compares the ratio of motor negative sequence current (I_2) to the positive

sequence current (I_1) times an adjustment factor to compensate for the actual motor load to a set threshold. The

adjustment factor is used to prevent nuisance alarms at light loads. If the motor is operating at an average current level

equal to or greater than the programmed full load current (FLA, as selected by the

SYSTEM SETUP MOTOR MOTOR

FULL LOAD AMPS

setting) the adjustment factor is one. If the motor is operating at an average current level less than the

programmed full load current (as selected by the

SYSTEM SETUP MOTOR MOTOR FULL LOAD AMPS setting) the

adjustment factor is the ratio of average current to full load current. It is intended that the Amp Unbalance 1 element is

used to generate an alarm and Amp Unbalance 2 element is used to generate a trip.

A declaration of a “single-phasing” condition is made two seconds after the unbalanced current level exceeds 40%, or the

average current is above 25% of FLA and the current in any one phase is less than 2% of FLA.

AMP UNBAL 1(2) PICKUP — This setting selects the level of unbalanced current that generates a stage 1 (intended to alarm)

output. Note that a supply voltage unbalance of 1% creates a current unbalance of 6% in a typical three-phase induction

motor; a supply voltage unbalance of 2% creates a current unbalance of 12%. As a 2% voltage unbalance is common in

most applications, a setting of 0.15 is often used as the alarm level, and

AMP UNBAL 1 PICKUP is usually set to this level or

higher.

AMP UNBAL 1(2) PICKUP DELAY — The alarm delay is often set from 5 to 10 seconds. A higher level of unbalance causes

motor stress in a shorter period; a reasonable setting is 3 to 10 seconds.

AMP UNBAL 1(2) RESET DELAY — This timer can be used to maintain the output until other equipment or an operator can

react to the unbalance condition.

Figure 5-117: AMP unbalance logic

5.7.3.5 Mechanical jam

SETTINGS GROUPED ELEMENTS SETTING GROUP 1(6) MOTOR MECHANICAL JAM

AMP UNBAL 1 EVENTS:

Disabled

Range: Disabled, Enabled

MECHANICAL JAM

MECHANICAL JAM

FUNCTION: Disabled

Range: Disabled, Enabled

MECH JAM OVERCURRENT

PICKUP: 2.00 x FLA

Range: 1.00 to 10.00 x FLA in steps of 0.01

Loading...

Loading...