913323/CP0112 14 PRINTED IN U.S.A.

24. The platform must be fully lowered for personnel

to enter and exit. Personnel must not climb on any

part of the forklift in attempting to enter and exit.

25. Any harness, body belt, lanyard, or deceleration

device that has sustained permanent deformation

or is otherwise damaged must be replaced.

26. Modifications to the platform that are detrimental

to its safe use are prohibited.

Work Platform Design Requirements

(Per ANSI/ITSDF B56.6-2005, Sec. 8.24)

1. A platform floor having a slip-resistant surface

located not more than 8 inches (200 mm) above the

normal load-supporting surface of the forks.

2. Floor dimensions, which shall not exceed two

times the load center distance of 24 inches (610

mm) listed on the forklift nameplate, measured

parallel to the longitudinal center plane of the fork-

lift, nor have a width greater than the overall width

of the forklift [measured across the load-bearing

tires] plus 10 inches (250 mm) on either side.

Minimum space for each person on the platform

shall not be less than 18 inches (450 mm) in either

direction.

3. A 4 inch (100 mm) minimum height toe plate,

which may be omitted at the access opening.

4. An overhead protective device, when requested by

the user.

5. Protection for personnel in their normal working

position on the platform from moving parts of the

forklift that may present a hazard.

6. Information prominently indicated on the plat-

form:

a. maximum work load including personnel and

equipment, and

b. weight of empty platform.

SAFETY

WARNING

Use ONLY an approved work platform for ele-

vating personnel.

NEVER move the machine with the work plat-

form in a raised position or with personnel on

board.

NEVER tilt the platform forward, rearward, or

to the side with personnel aboard.

ALWAYS engage the PWP System and follow

the Mandatory Work Platform Safety Rules

when elevating personnel.

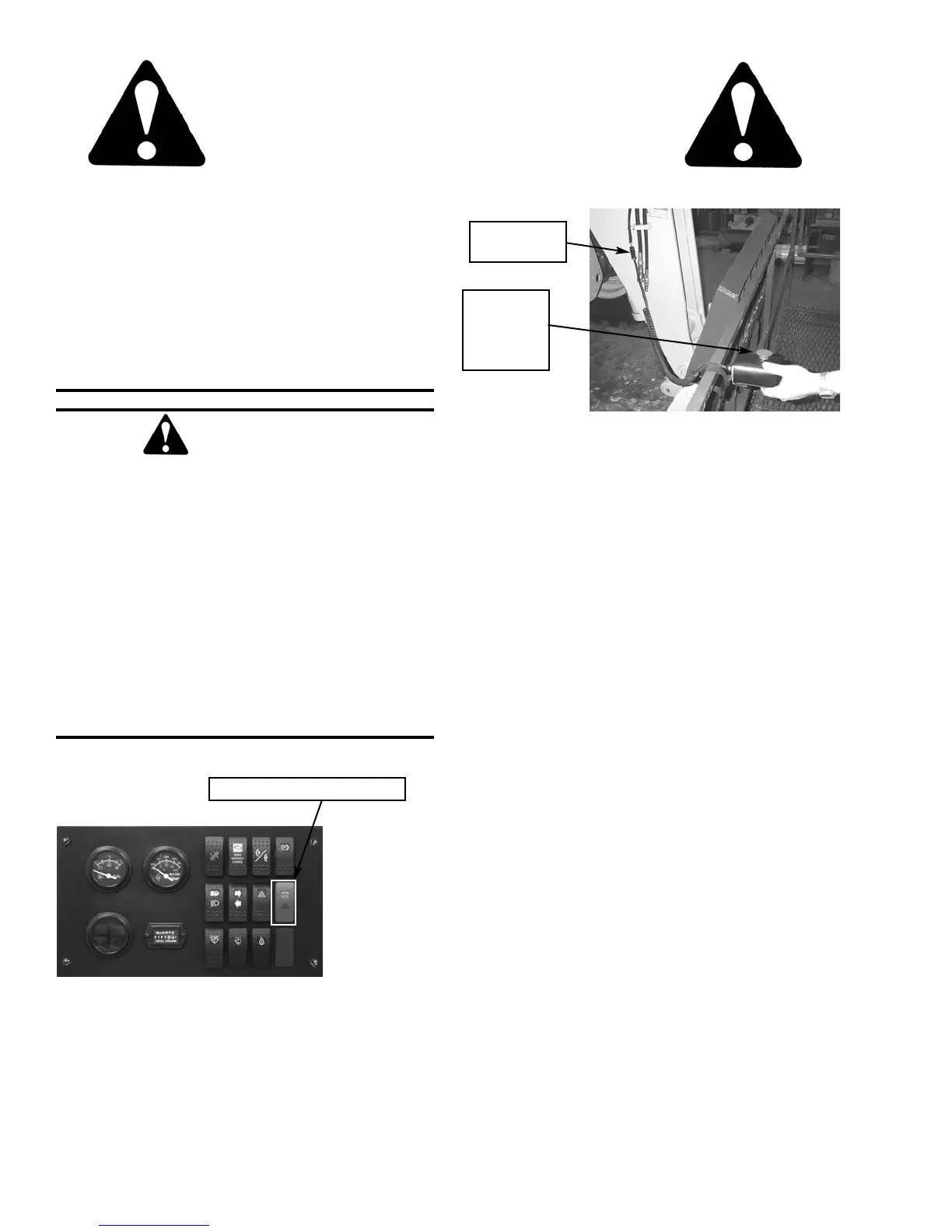

Work Platform System Switch

PWP

Remote

Shutdown

Switch

Electrical

Connection

Remote Shutdown Switch

with Coiled Wire Connector

Loading...

Loading...