913323/CP0112 40 PRINTED IN U.S.A.

SUSPENDED LOADS

The handling of suspended loads by means of a truss

boom or other similar device can introduce dynamic

forces affecting the stability of the machine that are not

considered in the stability criteria of industry test stan-

dards. Grades and sudden starts, stops and turns can

cause the load to swing and create a hazard.

Guidelines for “Free Rigging / Suspended

Loads”

1. DO NOT exceed the rated capacity of the tele-

scopic handler as equipped for handling suspend-

ed loads. The weight of the rigging must be

included as part of the load.

2. During transport, the length of the rigging between

the attachment and load should be as short as pos-

sible to reduce booms height and movement. DO

NOT raise the load more than 12 inches (305 mm)

above the ground, or raise the boom more than 45

degrees.

3. Only lift the load vertically – NEVER drag it hor-

izontally.

4. Use multiple pickup points on the load when pos-

sible. Use taglines to restrain the load from

swinging and rotating.

5. Start, travel, turn and stop SLOWLY to prevent

the load from swinging. DO NOT exceed walking

speed.

6. Inspect rigging before use. Rigging must be in

good condition and in the U.S. comply with

OSHA regulation §1910.184, “Slings,” or

§1926.251, “Rigging equipment for material han-

dling.”

7. Rigging equipment attached to the forks must be

secured such that it cannot move either sideways

or fore and aft. The load center must not exceed

24 inches (610 mm).

8. DO NOT lift the load with anyone on the load,

rigging or lift equipment, and NEVER lift the

load over personnel.

9. Beware of the wind, which can cause suspended

loads to swing, even with taglines.

10. DO NOT attempt to use frame-leveling to com-

pensate for load swing.

ROAD TRAVEL

For short distance highway travel, attach a Slow-

Moving Vehicle (SMV) emblem (purchased locally) to

the rear of the Telescopic Handler. For highway opera-

tion, obtain and install an amber flashing beacon.

NOTE: ALWAYS follow ALL state and local regu-

lations regarding the operation of equipment on or

across public highways. Whenever there is an

appreciable distance between jobsites, or if

driving on public highway is prohibited, transport

the machine using a vehicle of appropriate size

and capacity.

TRANSPORTING BETWEEN JOB-

SITES

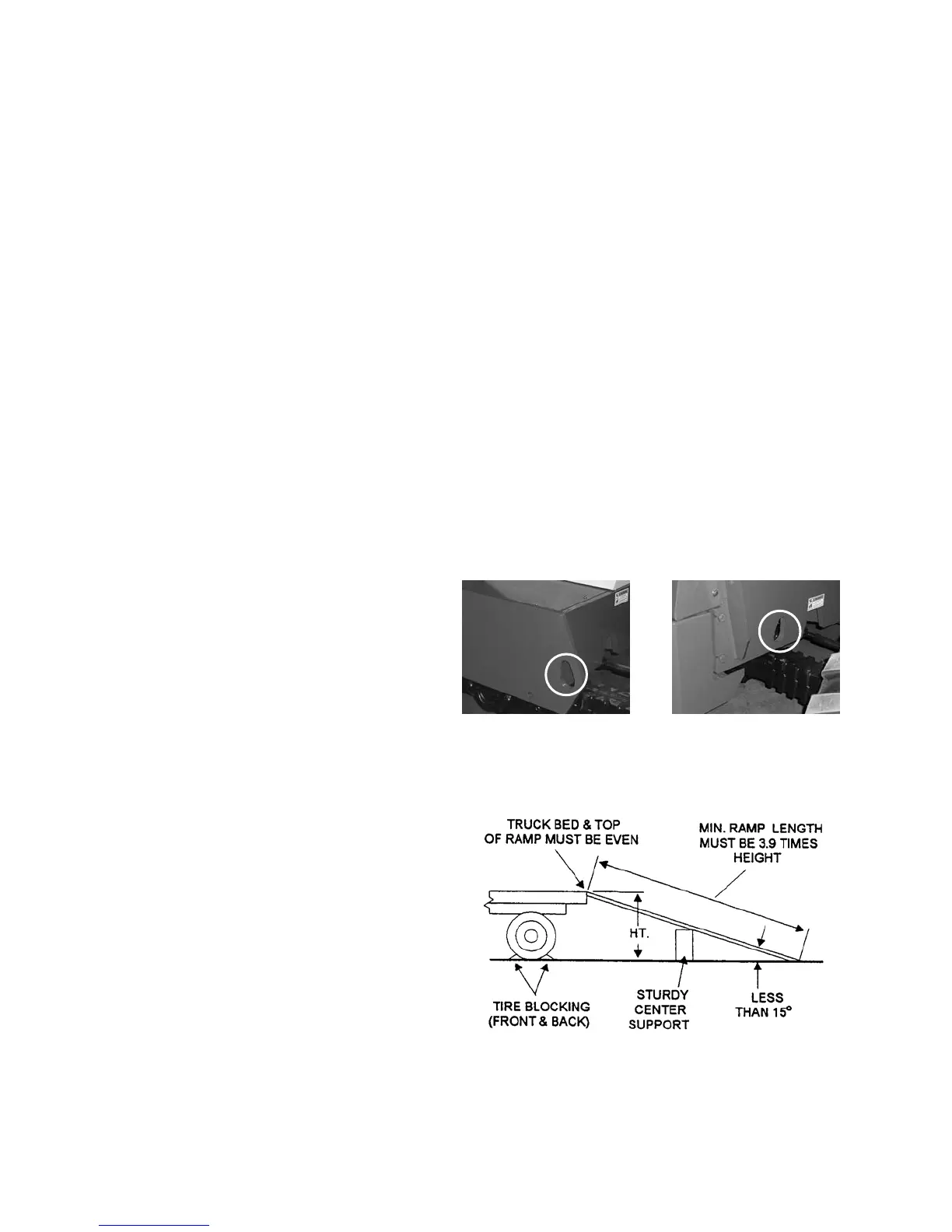

ALWAYS abide by the following recommended proce-

dures and guidelines when using ramps to load the

machine onto (and unload it from) a truck or trailer.

Failure to heed can result in damage to equipment and

serious personal injury or death!

Tie-down eyes are provided for inserting chains

through to secure the machine during transporting.

Loading Machine Using Ramps

NOTE: A matched pair of ramps is required.

1. The ramps MUST be of sufficient strength to sup-

port the machine. The use of strong steel ramps is

recommended, as well as center supporting blocks.

Front Tie-Down Rear Tie-Down

Ramp Placement

Loading...

Loading...