913323/CP0112 56 PRINTED IN U.S.A.

measures 10.3” (262 mm) or more, the chain should be

replaced. DO NOT repair sections of a chain. Replace

the complete chain.

Chain anchors and sheaves also require inspection, for

worn or broken fingers and worn flanges.

After any chain has been replaced, operate under

loaded conditions and re-check the torque. Adjust the

chains per the following procedure: Extend the boom

to its maximum length, then retract the boom slowly

until the chain slack allows the chain to rest on the top

of the boom. Torque the two chains on the front of the

boom to 25 ft.-lbs. (34 Nm). Lubricate with 80W-90

oil.

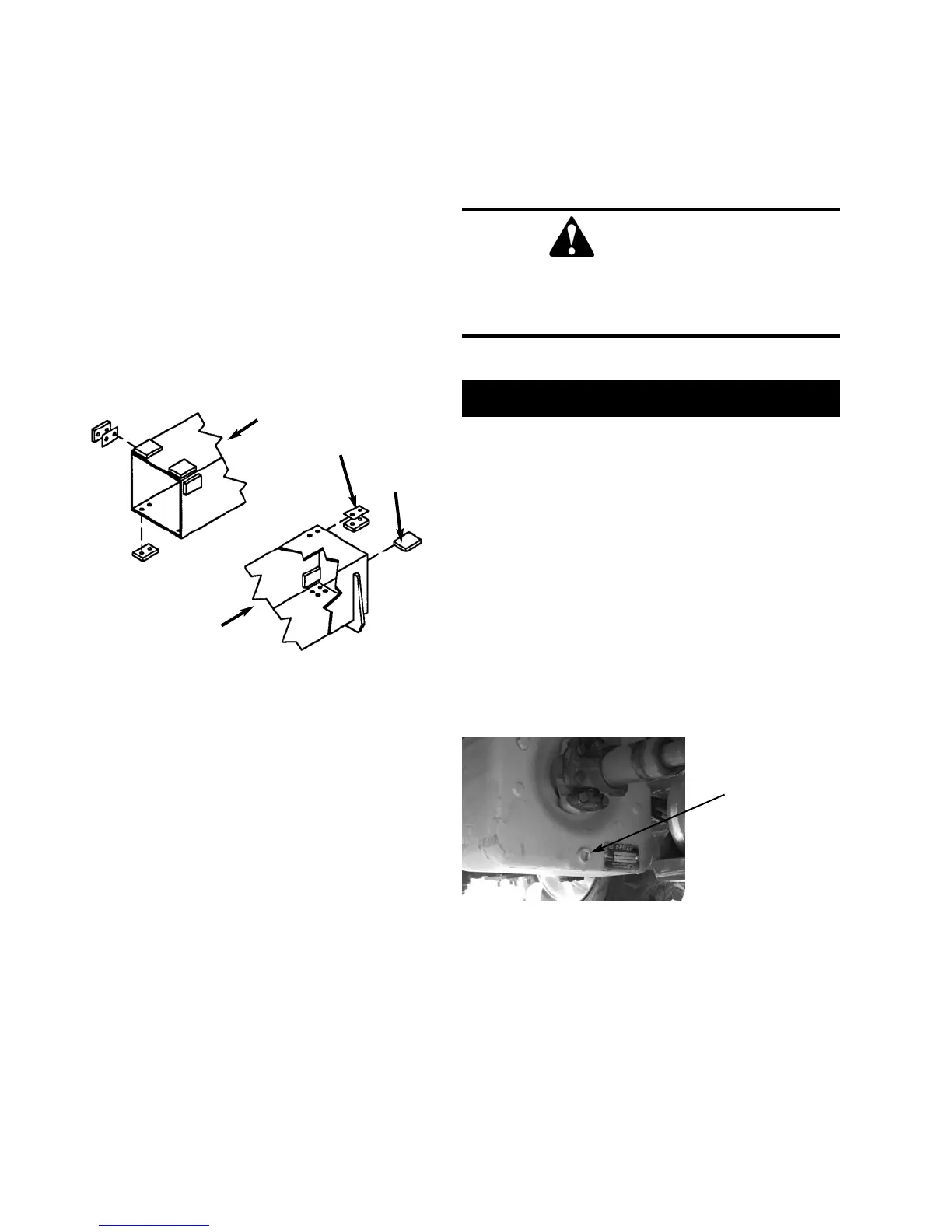

CHECKING BOOM SLIDE PAD WEAR

AND CLEARANCE

The boom is equipped with special nylon low-friction

slide pads between the telescopic sections (see illustra-

tion). These are pre-greased and initially worn-in at the

factory. Normally greasing is not required, except for

maintaining a light film of grease on the pad tracking

areas of the boom sections. An exception is if a boom

section has been replaced.

Visually check for loose pad bolts. The bolts are

torqued to 30 ft.-lbs. (40 Nm). If the bolts are re-

torqued at any time, Loctite® thread lock must be re-

applied to the bolts.

If the boom starts to chatter under load, grease the slide

pads and wipe off the excess grease. Maintain a clear-

ance of 1/16” between the top or side slide pads and the

boom. Shims can be added to achieve the proper clear-

ance. Loosen the bolts and insert shims until proper

clearance is obtained.

NOTE: When inserting shims in the side slide

pads, be sure to place equal shims on both sides

of the boom for even distribution of clearance.

Re-apply Loctite® 271 (red) thread lock or equivalent

to the bolts and re-torque to 30 ft.-lbs. (40 Nm).

Bottom slide pads should not be shimmed and should

be replaced when the thickness is worn down to 3/8”

(9.5 mm).

NOTE: Perform all other service requirements

up to this point as well as the following:

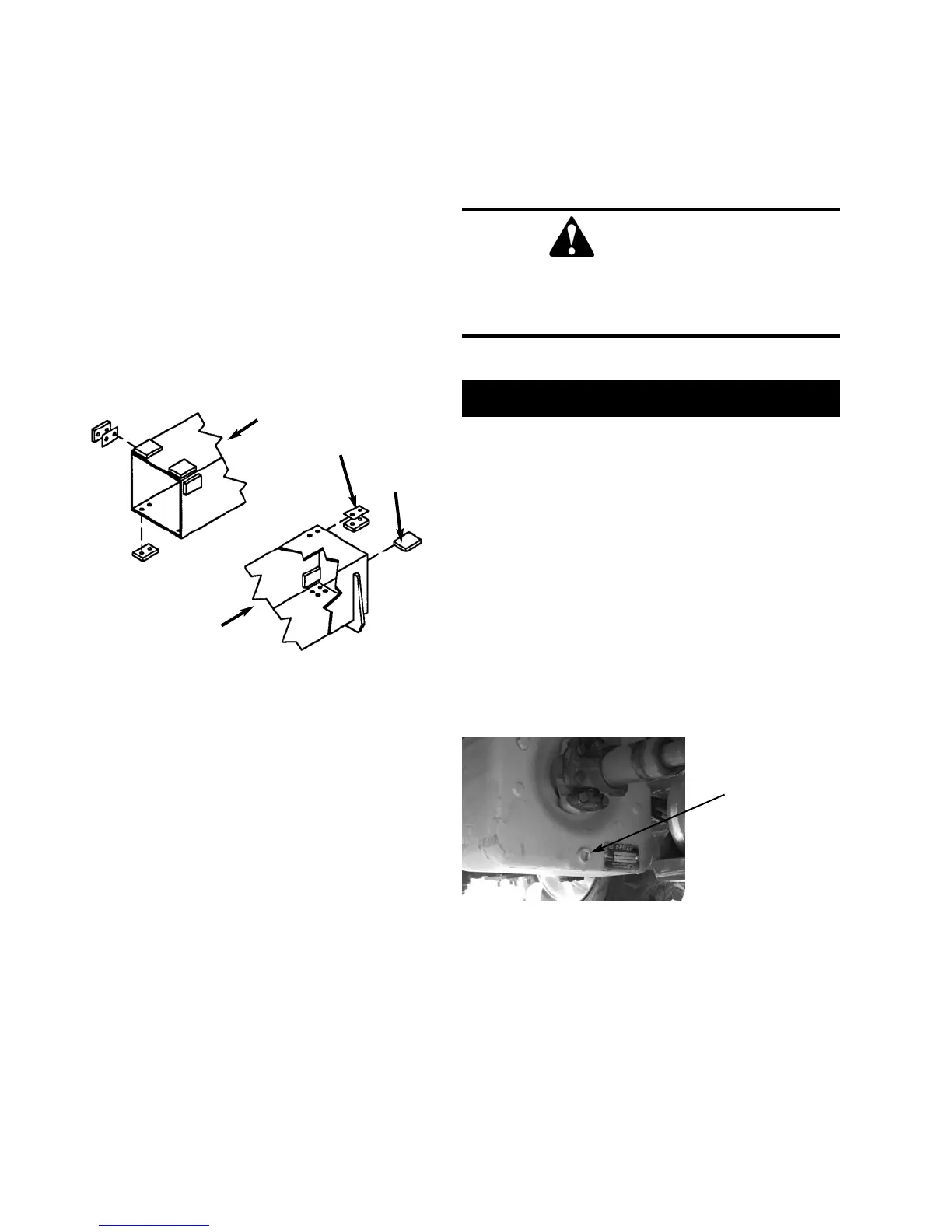

CHANGING TRANSMISSION OIL AND

FILTER

Operate the machine long enough to warm the trans-

mission oil to 150°-200°F (65°-93°C). Shut off the

engine. Access to filter is from under the access cover

on the front hood section. Access to the drain plug is

from underneath the machine. Proceed as follows:

1. Remove the drain plug and drain oil. Replace the

drain plug.

IMPORTANT: DO NOT discharge oil onto ground.

Catch and dispose of per local waste disposal

regulations.

2. Remove and discard the oil filter. Wipe the sealing

surface on the transmission with a clean cloth.

Apply a thin coat of clean oil to the new oil filter

gasket. Hand tighten.

3. Refill the transmission with new oil as shown in

the Lubrication chapter of this manual.

Service Every 1000 Hours or Yearly

WARNING

Failure to maintain proper slide pad clearance

and thickness could cause damage to the

boom, resulting in sudden boom failure.

Transmission

Drain Plug

Slide Pad Detail

Rear Inner

Front Outer

Pad

Shim

Loading...

Loading...