Generac

®

Power Systems, Inc. 25

2. Check the devices while the generator is running.

If the E Panel is still shutting down on low coolant

level, and both devices check good in the power

down state, the devices can be checked while the

engine is running. The following tests will isolate

the two different senders and determine which

sender is causing the shutdown.

NOTE:

It is very important that the wiring between the E

Panel and the LCL/HWT was carefully checked as

described above. Incorrect wiring or damage to

any of the wiring can result in false test results.

2.1 Test the HWT switch.

2.1.1 Disconnect the 85 wire connected to

the LCL. Position the wire such that the

lug will not come into contact with any

metal surface.

2.2.2 Start and run the generator. If the gen-

erator shuts down with a low coolant

level alarm, the HWT switch is the

cause. Replace the HWT switch.

If the generator does not shut down on

alarm, stop the generator and proceed

to the next test.

2.2 Test the LCL sender.

2.2.1 Reconnect the 85 wire to the LCL.

2.2.2 Disconnect the 85 wire connected to

the HWT switch. Position the wire such

that the lug will not come into contact

with any metal surface.

2.2.3 Start and run the generator. If the gen-

erator shuts down with a low coolant

level alarm, the LCL is the cause.

Replace the LCL.

If the generator does not shut down on

alarm, stop the generator manually.

2.2.4 Reconnect the 85 wire to the HWT.

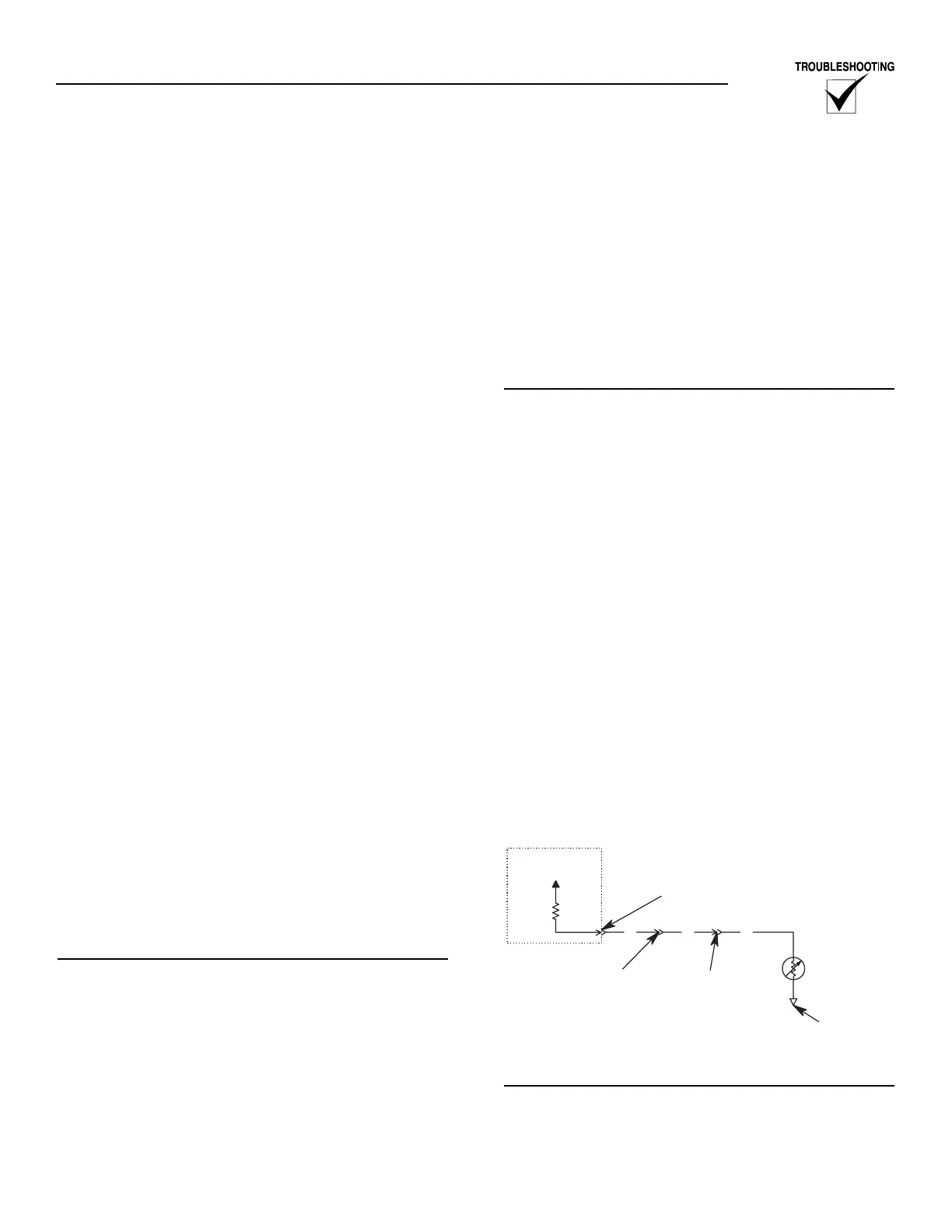

COOLANT TEMPERATURE SENSING

(Refer to Figure 3.3)

OVERVIEW

An analog Water Temperature Sender (WTS) is locat-

ed in the engine's cooling system. This sender is con-

nected to the E Panel and allows the E Panel to mon-

itor and display the temperature of the Coolant sys-

tem. Wire number 68 is used to connect the WTS to

the E Panel. The ground for the WTS is made through

the radiator frame or engine block (depending on

where the WTS is located).

Refer to the owners manual for the WTS part number

and mounting location.

The WTS is a resistive device whose resistance

changes based on coolant temperature. The resist-

ance of the sender results in a voltage being devel-

oped across the sender. As the Coolant temperature

increases, the resistance will decrease, causing the

voltage to decrease. This changing voltage is read by

the E Panel and converted into coolant temperature.

The E Panel will monitor and display the coolant

temperature anytime the DC input to the E Panel is

present.

TROUBLESHOOTING

Prior to any troubleshooting, the Coolant

Temperature parameters programmed into the E

Panel should be checked and verified. The coolant

temperature has three different set points associated

with it. They are:

• Low Coolant Temp Warning: This is a warning set

point. The generator's alarm will sound, but the

unit will continue to run.

• Pre-High Coolant Temp Warning: This is a warn-

ing set point. The generator's alarm will sound, but

the unit will continue to run.

• High Coolant Temp Alarm: This is the alarm set

point. The generator will shut down and sound the

alarm.

It is important to verify that these parameters are set

correctly for the specific unit. Check the E Panel set-

tings against the generator setup sheet. If the genera-

tor setup sheet is not available, contact Generac's

service department for the recommended settings.

Figure 3.3 — Water Temperature Sender

Connections

TESTING THE CONTROL PANEL

It is relatively easy to do a thorough test of the E

Panel's Coolant Temperature input.

Place the Auto/Off/Manual switch to the Off position

during this testing.

Loading...

Loading...