Generac

®

Power Systems, Inc. 31

2.1.3 Shield/Drain wire. The shield is an alu-

minum foil shield that surrounds the

two conductors and runs the entire

length of the cable. The foil shield will

be cut even with the cable jacket.

The drain wire is a non insulated wire

that is in physical contact with the

shield and also runs the entire length of

the cable. The drain wire is used to

make the shield connections.

The drain wire MUST be connected to

system ground to shield the sensitive

RPM sensor signal from noise. This

ground connection is typically made at

the control panel main terminal strip.

Refer to Figure 3.6.

2.2 Check the cable at the RPM sensor. Look for

breaks, signs of over stress, excessive ten-

sion, etc.

2.3 Check all of the connection points along the

entire cable run (refer to the unit's wiring dia-

grams.) At each connection point, check for

proper wire stripping, lugging, etc.

2.4 Drain wire connections. Carefully check the

drain wire connections at each connection

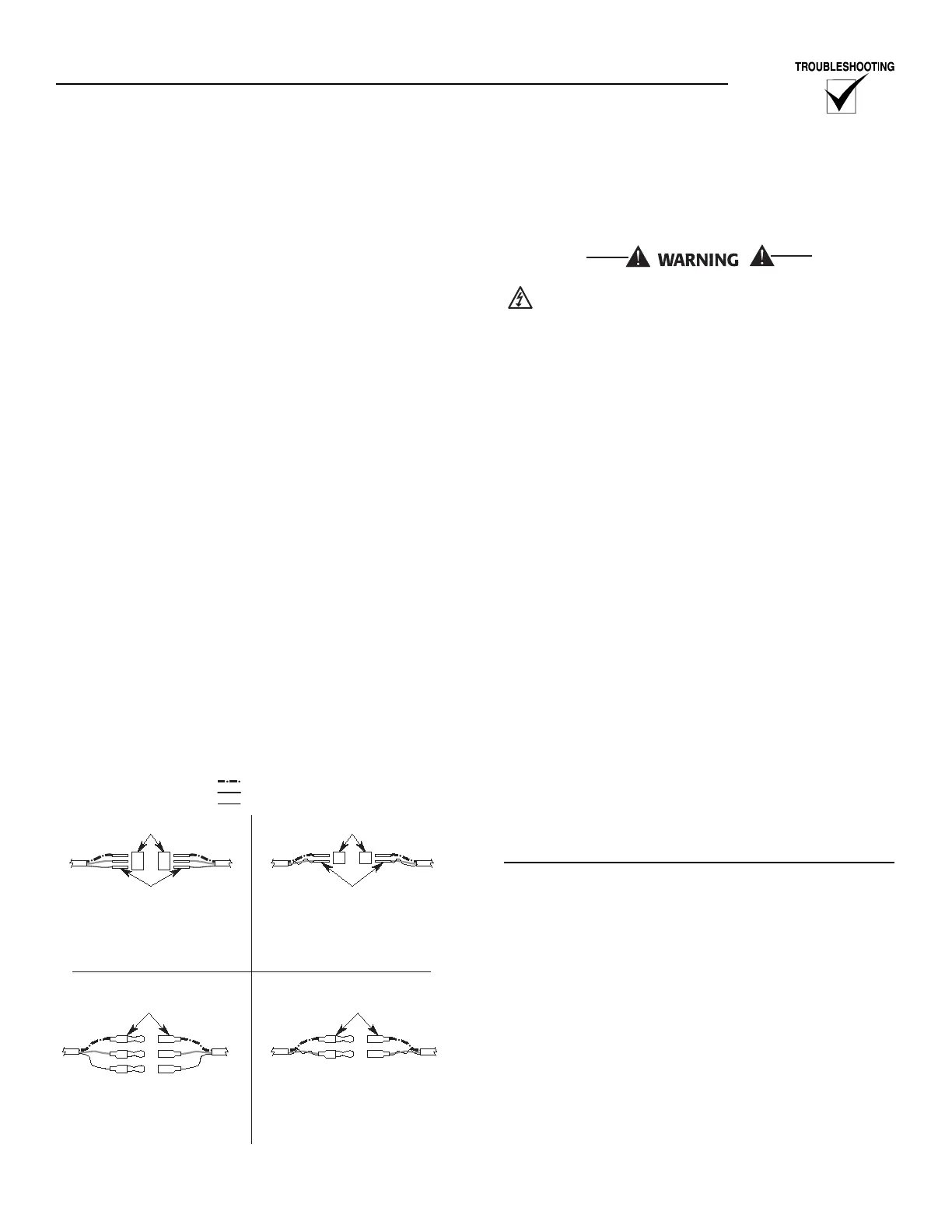

point. Figure 3.7 shows the different methods

that may be used for connecting the drain

wire. Note that the drain can be connected to

the 0 wire at a connection point, or it can be

run separately.

Figure 3.7 — RPM Sensor Engine Connections

3. RPM sensor voltage measurement. The RPM sen-

sor voltage can be measured at the control panel's

main terminal strip. This voltage should be meas-

ured during crank and run.

Once the engine has started, there will be high

voltage inside the generators control panel.

3.1 Using an AC volt meter, measure the voltage

at terminal positions 79 and 0.

This voltage should measure as follows:

During crank: 150 milli volts or greater

(0.150V)

During run: 500 milli volts or greater

(0.500V)

3.2 If the voltages measured are lower than what

is listed above do the following:

3.2.1 Reset the RPM sensor. Refer to Figure

3.5 for the proper setting.

NOTE:

The RPM sensor will have to be removed in order

to be set properly. Do not strain (twist) the sender

cable during this process. Units that have a con-

nector at the sender can simply be disconnected.

If a connector is not available, the cable will have

to be removed from the wire harness and discon-

nected at the control panel.

3.2.2 Retake the voltage measurements. If

the voltages are still low, then the RPM

sender is faulty and should be

replaced.

ENGINE DOES NOT CRANK

This section provides troubleshooting techniques

that should be used if the engine fails to crank when

a start signal is given.

CHECK THE E PANEL START SETTINGS

All of the following start related parameters will be

found in the Engine Parameters Menu.

These settings should be checked against the

Generator setup sheet. If the generator setup sheet is

not available, contact Generac's service department

for the recommended settings.

1. Number of start attempts. This number defines

the maximum number of times the E Panel will

engage the starter. Verify this number is not set to

zero.

2. Start timer. This number (in seconds) defines the

length of time the E Panel will keep the starter

energized during a start attempt. Verify this num-

ber is not set to zero.

3. Start attempt pause time. This number (in sec-

onds) defines the length of time the E Panel will

pause between start attempts.

Loading...

Loading...