30 Generac

®

Power Systems, Inc.

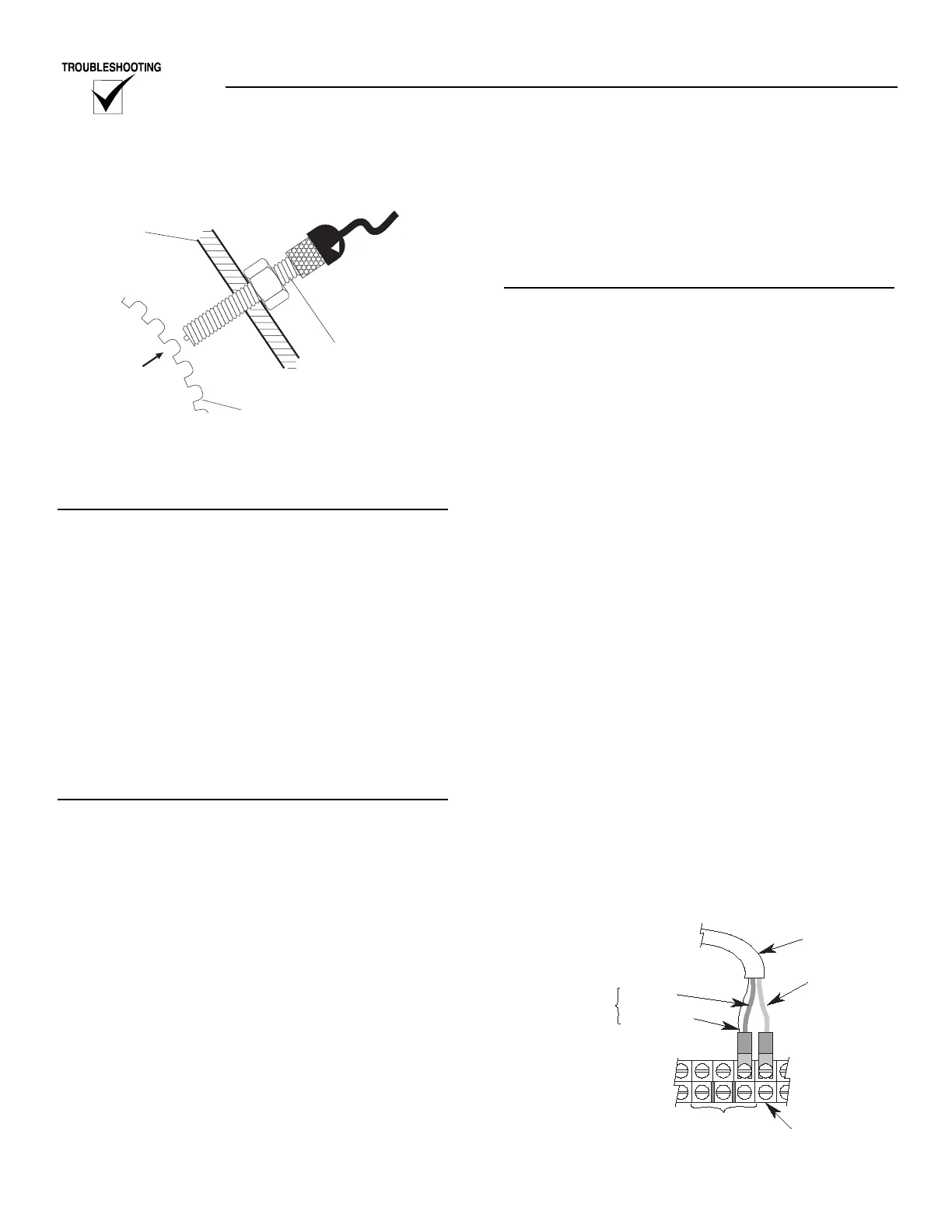

Figure 3.5 — RPM Sensor

If the magnetic pickup is removed for any reason, it

must be installed properly.

INSTALLATION

1. Rotate the ring gear until a gear tooth face is

directly in the center of the tapped hole on the

blower housing.

NOTE:

Do NOT use the alternator fan to rotate the engine.

2. Gently turn the magnetic pick up clockwise into

the tapped hole until it bottoms on the gear tooth.

3. Use a marker to mark a line on the magnetic pick

up threads and blower housing.

4. Using the lines marked in Step 3 as a guide, turn

the magnetic pick up 1/2 to 3/4 of a turn counter-

clockwise.

5. Tighten the jam nut securely.

RELATED ALARMS

RPM Sensor Loss

RPM sensor loss is a shut down alarm. There are two

conditions that will result in RPM sensor loss.

1. No RPM signal at crank. The E Panel will monitor

the RPM sensor during the crank cycle. If no sig-

nal is detected within a few seconds of cranking,

the E Panel will display RPM Sensor Failure and

shut down the engine.

2. RPM sensor loss while running. The E Panel con-

tinues to monitor the RPM sensor while running.

If the signal is lost while running, the E Panel will

display RPM sensor failure and shut down the

engine.

Engine Under Speed

Engine under speed is a hold off alarm with a pro-

grammable set point. The alarm type is programma-

ble as shutdown, latched, non-latched or status.

Engine Over Speed

Engine over speed is an immediate alarm with a pro-

grammable set point. Engine over speed is a shut

down alarm.

TROUBLESHOOTING

1. Verify that all the following parameters have been

correctly programmed into the E Panel.

1.1 Number of flywheel teeth. The number of fly-

wheel teeth is used by the E Panel to convert

the electrical pulses from the RPM sensor,

into engine speed. If this parameter is not

programmed correctly, the E Panel will not be

able to monitor engine speed correctly. Verify

the number of flywheel teeth against the gen-

erator setup sheet. If the generator setup

sheet is not available, contact Generac's serv-

ice department for the REQUIRED setting.

1.2 Over speed and under speed settings. Verify

these settings against the generator setup

sheet. If the generator setup sheet is not avail-

able, contact Generac's service department

for the recommended settings.

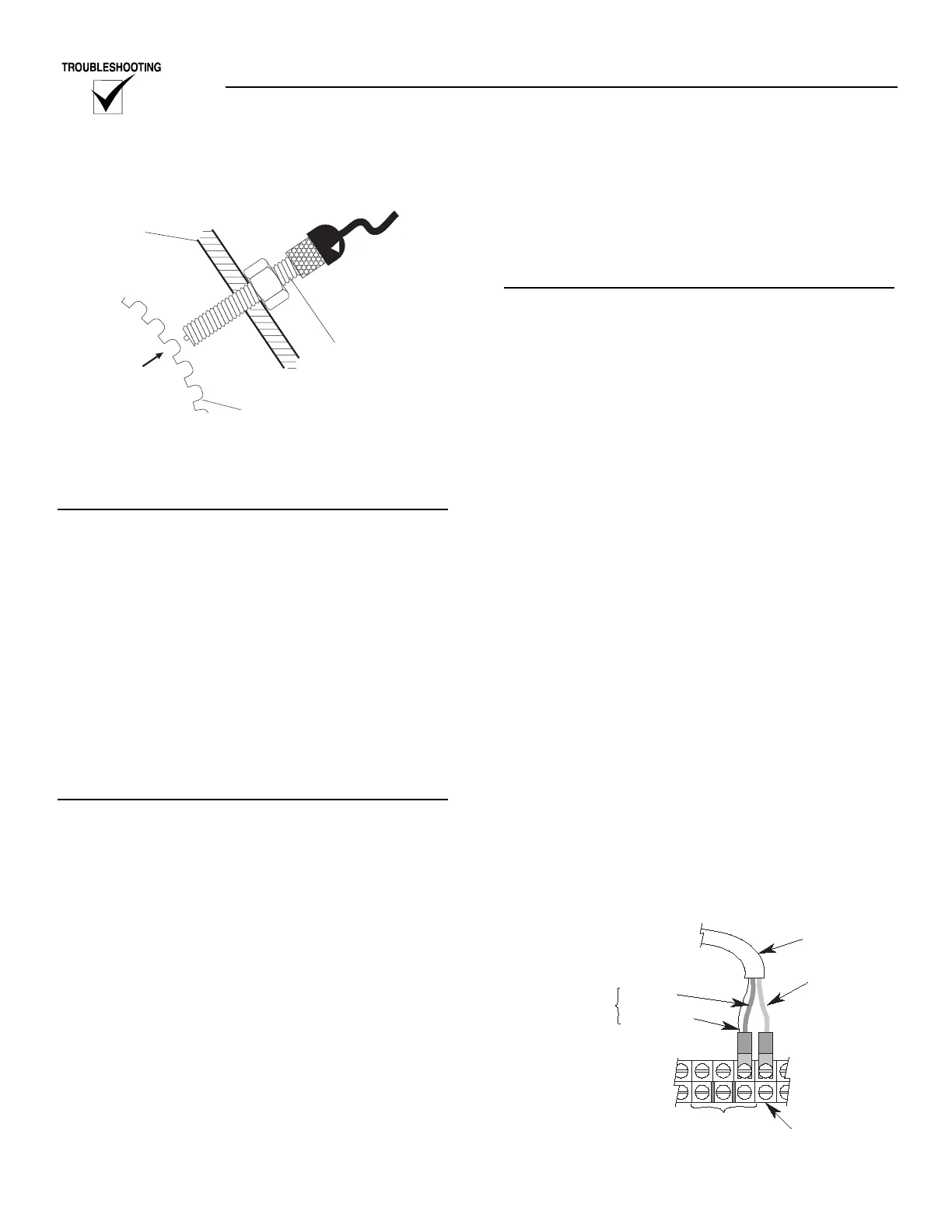

2. Check the RPM sensor wiring. A two conductor

shielded cable is used to connect the RPM sensor

to the E Panel. It is important to very carefully

check this wiring and all connections, including

the shield connections.

2.1 Cable description:

2.1.1 Red wire (wire 79). The red wire inside

the cable is wire number 79. This wire

is used to connect the RPM signal from

the sender to the E Panel.

2.1.2 Black wire (wire 0). The black wire

inside the cable is the 0 wire that con-

nects the RPM sensor to the E Panel.

Figure 3.6 — Control Panel RPM Sensor

Connections

Loading...

Loading...