KB300 / KB350 with FS560

Translation of the original operating instruction and spare parts list

- 42-

5006892-01

BA-E

®

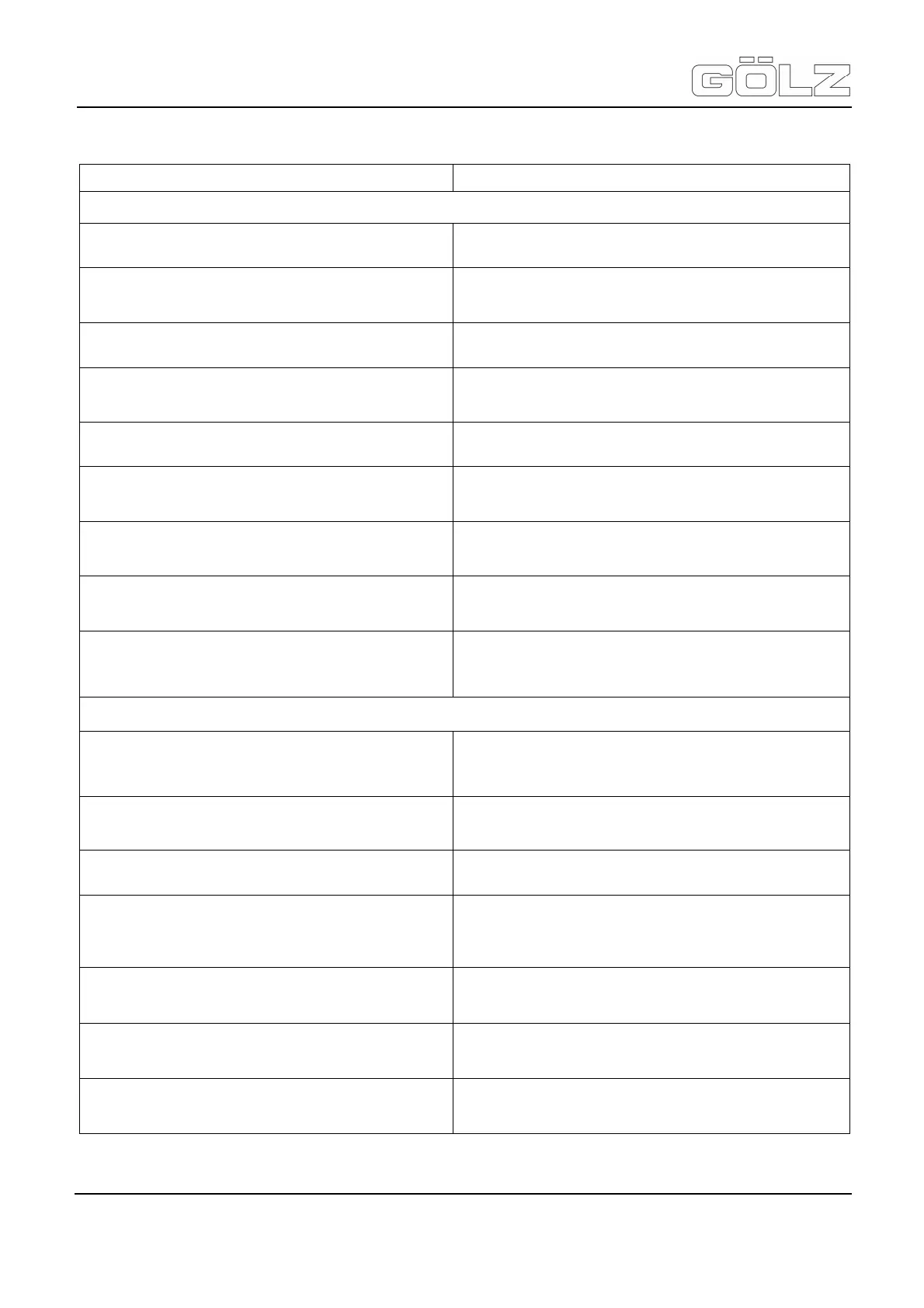

7. Troubleshooting

Cause Remedy

Blunt drill bit

Hard bonded segment!

Use segments one class softer bonded

Segment too big surface

Attach a drill bit with less segments or reduce the rpm

an increase the feed compression.

Too fast RPM!

Use lower RPM.

Drilling in steel!

Use lower gear and reduce feed and increase water

flow.

Drill bit worn out!

Replace with a new one.

Diamond grains pressed into the binding!

Sharpen drill bit in sharpening plate, work with low feed.

Segment surface is daubed with material sludge

Increase the water flow, re-sharp the segments

Segment surface is daubed with steel chips

Reduce the speed, increase the water flow, re-sharp

the segments

No free cut because of side wards wear-out of

segments!

Replace the drill bit and have the drill motor spindle

checked.

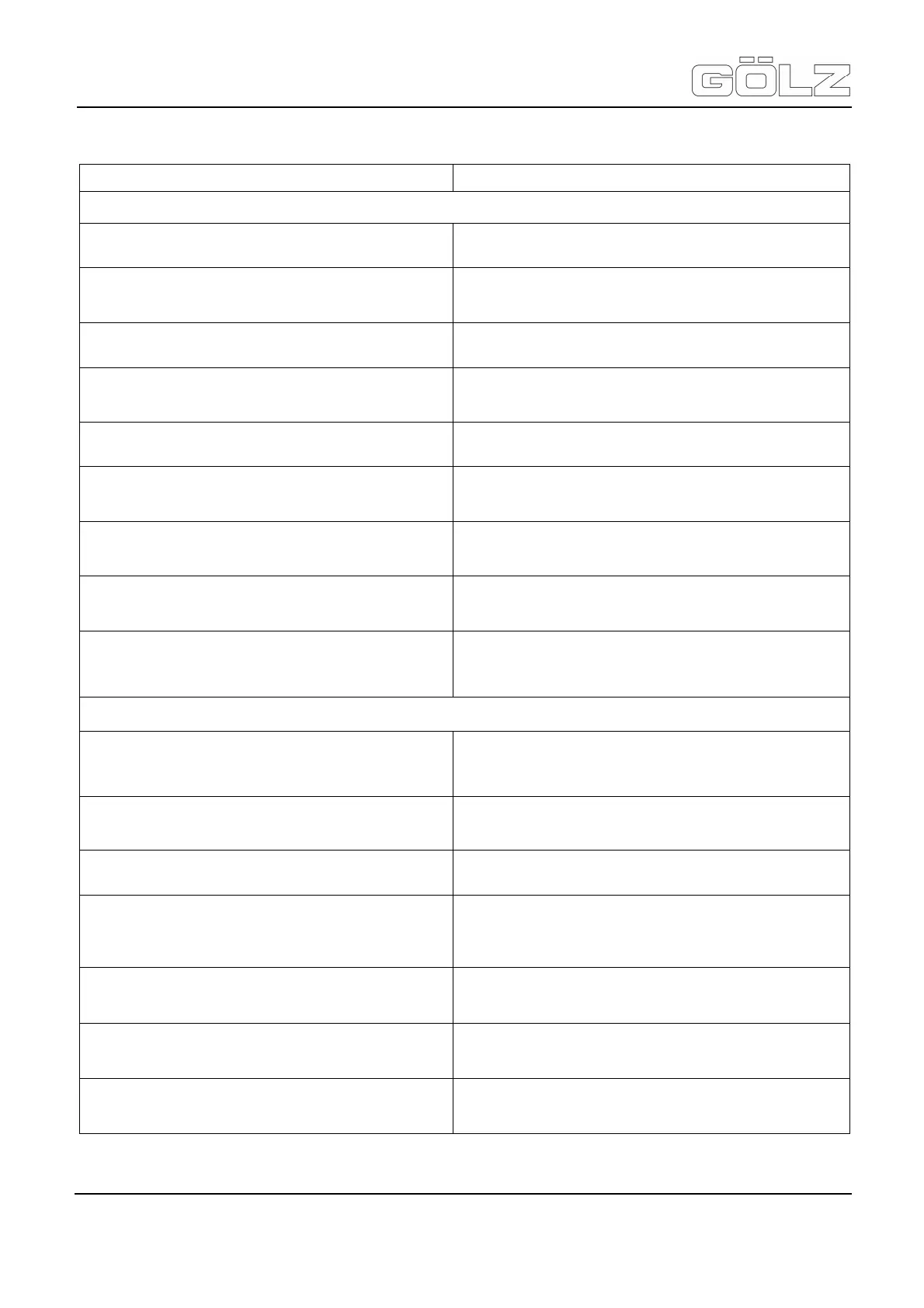

Excessive wear of segments

Soft bonded segments!

Use segments one class harder bonded or increase

rpm and reduce the feed compression

Segments to narrow!

Use drill bit with wider segments or reduce feed.

Too low RPM!

Shift the higher gear.

Drill bit is deformed!

Change drill bit for a new one and bring worn drill bit for

rebalancing. Check drill stem and adjust or replace it.

Do not use deformed drill bits - it is also wearing out the

drill motor.

Drill bit out of true!

Change drill bit and bring worn drill bit for re-balancing.

Abrasive material!

Use segments one class harder bonded. Increase the

water flow and the speed.

Water supply low!

Water supply raising.

Loading...

Loading...