Maintenance Procedures

313527ZAD 21

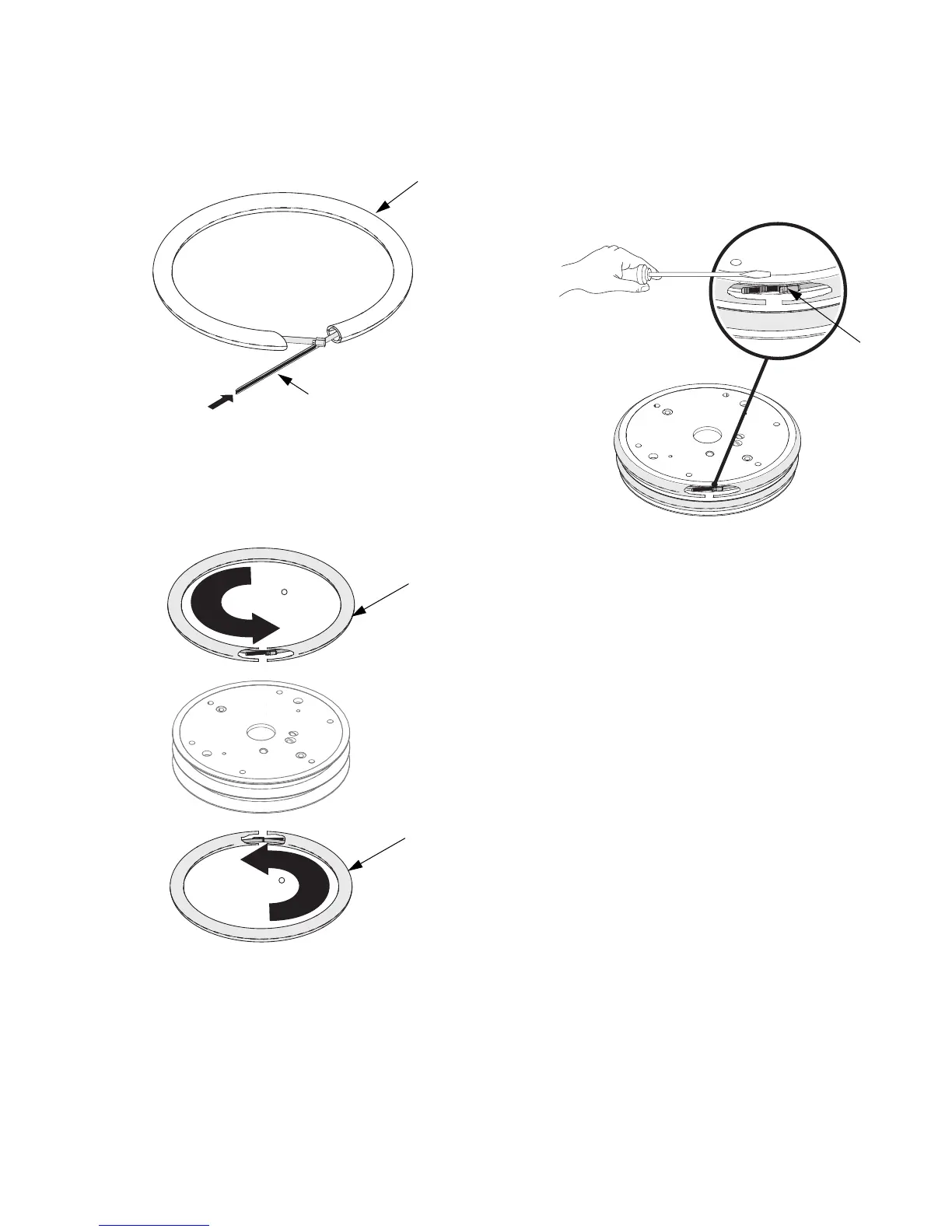

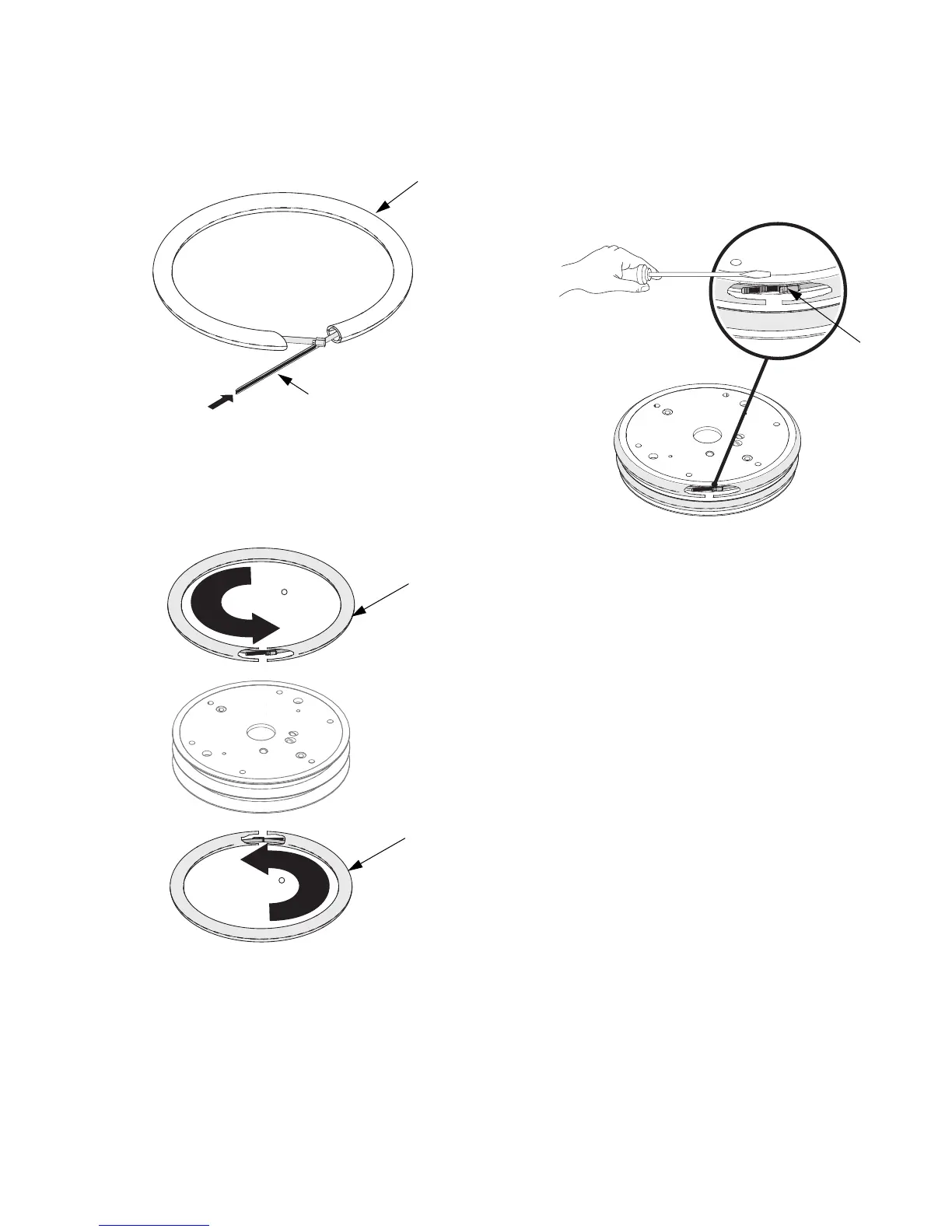

3. Insert jack screw end of band (410) into hose (408

or 409) and push completely through hose.

NOTE: To prevent material from potentially leaking past

both hoses, ensure hose (408,409) seams are 90°-180°

apart, and not on top of each other.

4. Lubricate outside of hoses (408,409) and place on

upper or lower groove on plate. Adjust hose and

band so that the angled ends of hose press against

each other. Tighten two ends of banding (410)

together with jack screw.

5. Work hose to completely close gap at the ends.

WLD

408, 409

410 (x2)

WLD

409

408

WLD

410

Loading...

Loading...