English (GB)

12

7. Electrical connection

The electrical connection must be carried out by an authorised

electrician in accordance with local regulations.

The operating voltage and frequency are marked on the motor

nameplate. Make sure that the motor is suitable for the power

supply on which it will be used and the motor terminal connection

is correct. You will find a wiring diagram in the terminal box.

7.1 Cable entry/screwed connection

All motors are supplied without screwed cable entries. The table

below shows the numbers and sizes of cable entry holes of the

terminal box (standard EN 50262).

7.2 Three-phase connection

1)

60 Hz motors, 0.37 - 1.1 kW: 220-277/380-440 V.

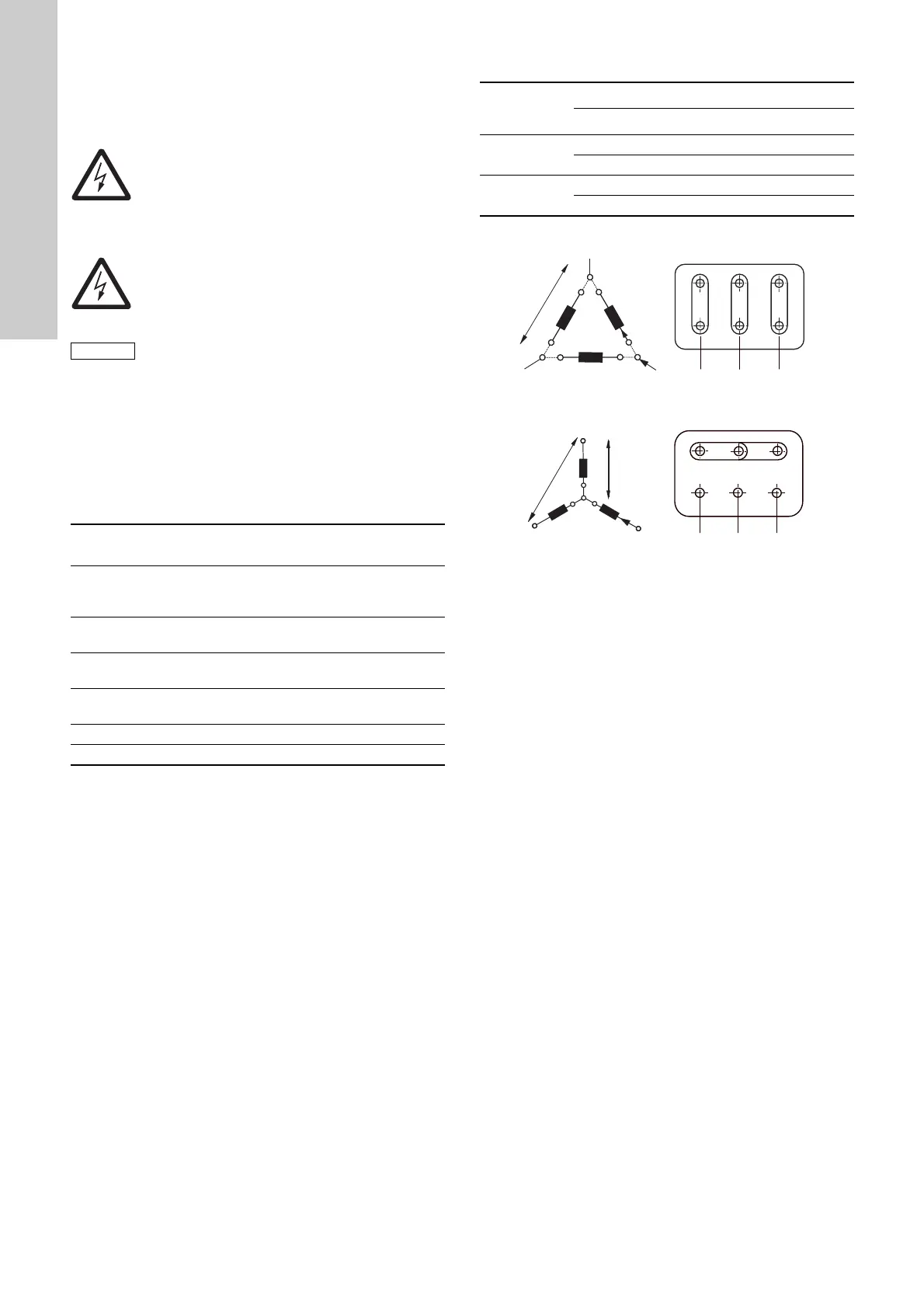

Fig. 15 Delta connection

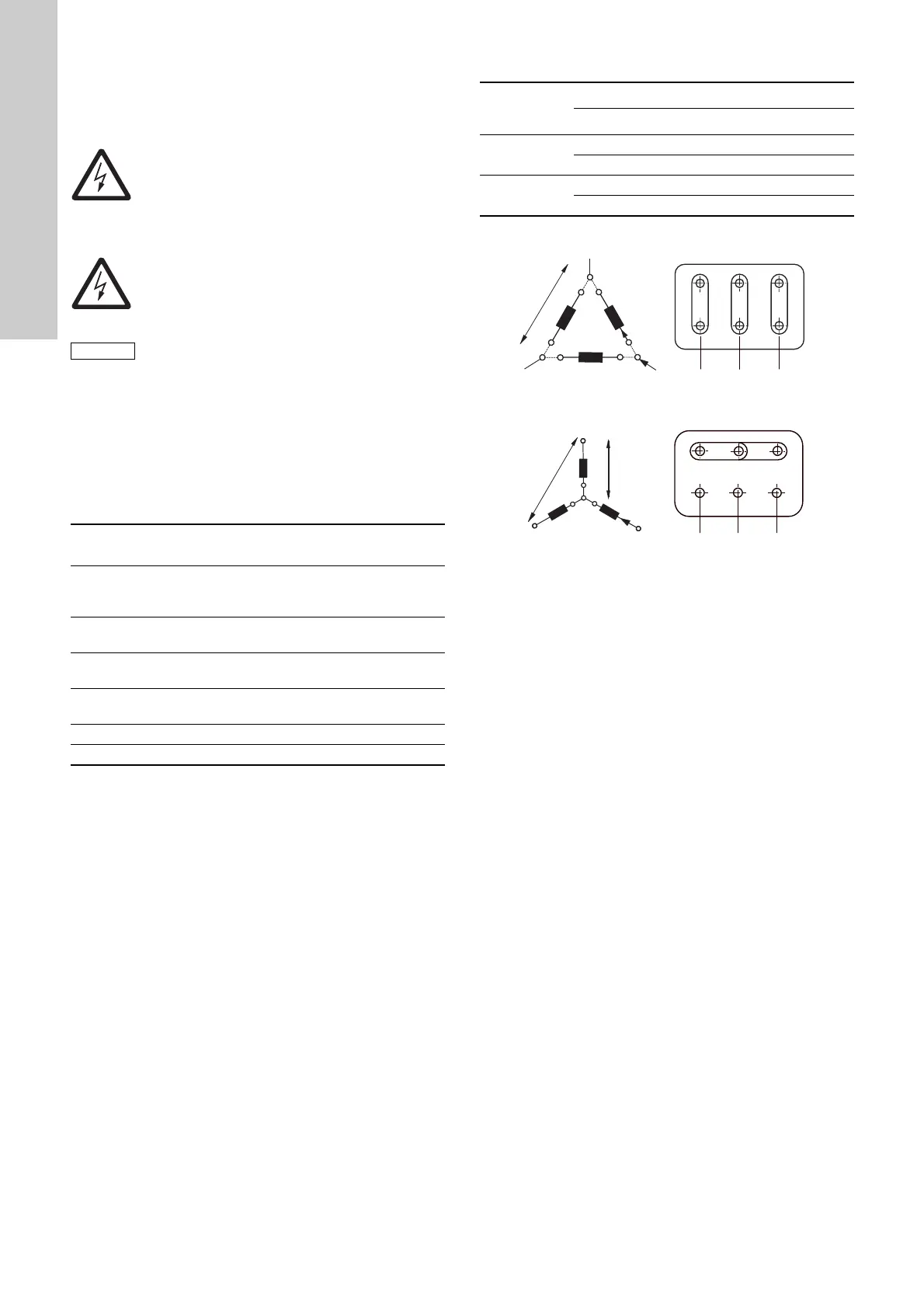

Fig. 16 Star connection

If the motor is provided with PTC sensors or PTO contacts, the

connection must be in accordance with the wiring diagram in the

terminal box.

Connect three-phase motors to a motor-protective circuit breaker.

Warning

Connect the CR pump to an external mains switch

placed close to the pump and to a motor-protective

circuit breaker or a CUE frequency converter. Make

sure you can lock the mains switch in OFF position

(isolated). Type and requirements as specified in EN

60204-1, 5.3.2.

Warning

Before removing the terminal box cover and before

removing or dismantling the pump, make sure that

the power supply has been switched off and that it

cannot be accidentally switched on.

Consider whether it is necessary to install an

emergency stop switch.

Motor

[kW]

Number and size

of cable entries

Description

0.25 - 0.55 2 x M20 x 1.5

The holes have precast

threads and are closed with

knock-out cable entries

0.75 - 3.0 2 x M20

The holes are closed with

knock-out cable entries

4.0 - 7.5 4 x M25

The holes are closed with

knock-out cable entries

11-22

2 x M20

4 x M40

The holes are closed with

knock-out cable entries

30-45 2 x M50 x 1.5 Blanking plug

55-75 2 x M63 x 1.5 Blanking plug

Mains supply [V]

Delta connection Star connection

50 Hz

220-240 / 380-415

380-415 / 660-690

60 Hz

220-277 / 380-480

1)

380-480 / 660-690

TM02 6656 1305TM02 6655 1305

W2 U2 V2

U1 V1 W1

U1

U2

V1

V2

W1

W2

L

3

L

2

L

1

W2

U2

V2

U1

U1

V1

V1

W1

U2

V2

W1

W2

L

3

L

2

L

1

Loading...

Loading...