73

Subject to change without notice

MANUAL ADJUSTMENT PROCEDURE HM1508-2

– Press “PROBE ADJ.” pushbutton, “COMP. TESTER On” function key and press AUTO/CURSOR-MEASURE

and SETTINGS pushbutton simultaneously to enter the “Settings Adjust” menu.

– Press “Adjust 1” function key.

– Press “RO Adjust” function key to enter the “Adjust 1 RO Adjust” submenu.

– Press “Trace Rot.” function key.

– Turn INTENS knob to adjust the Service Rectangle exactly parallel to the horizontal lines of the graticule.

– Press function keys to call “Y Position”, “Y Mag.”, “X Position” and “X Mag.” to adjust the Service Rectangle

until it is adapted to the graticule lines.

– Turn INTENS knob in combination with Y and/or X Mag function, to adjust the rectangle for 6 division height

and 8 division width.

– Turn INTENS knob in combination with Y and/or X Position function, so that the cross symbol in the center of

the Service Rectangle is congruent with the graticule center.

– Press “Save” function key to store the settings into user memory.

– Press REM pushbutton (EXIT MENU) to return to the Adjust Adjust 1 menu and continue with item 25.

– Check that Adjust Adjust 1 menu is present.

– Press “YP” function key to call the “Adjust 1 YP”

submenu.

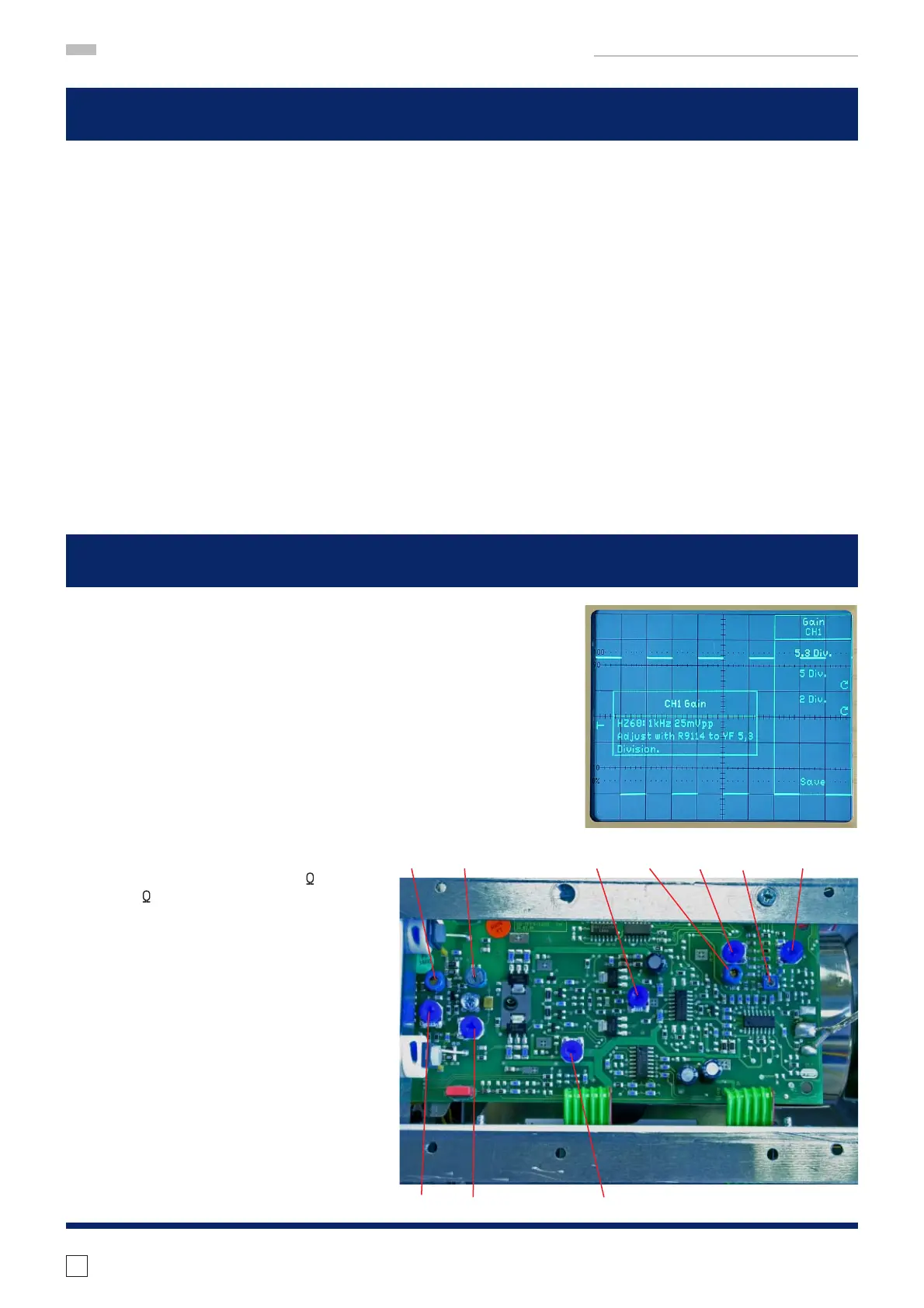

– Press “Gain” function key to call “YP Gain”

menu.

– Press “CH 1” function key.

– Press “5.3 Div.” function key.

– Connect a 25 mV

pp

(accuracy ± 0.1%), 1

kHz square wave signal via 50

cable

and 50 through terminator to input CH

1.

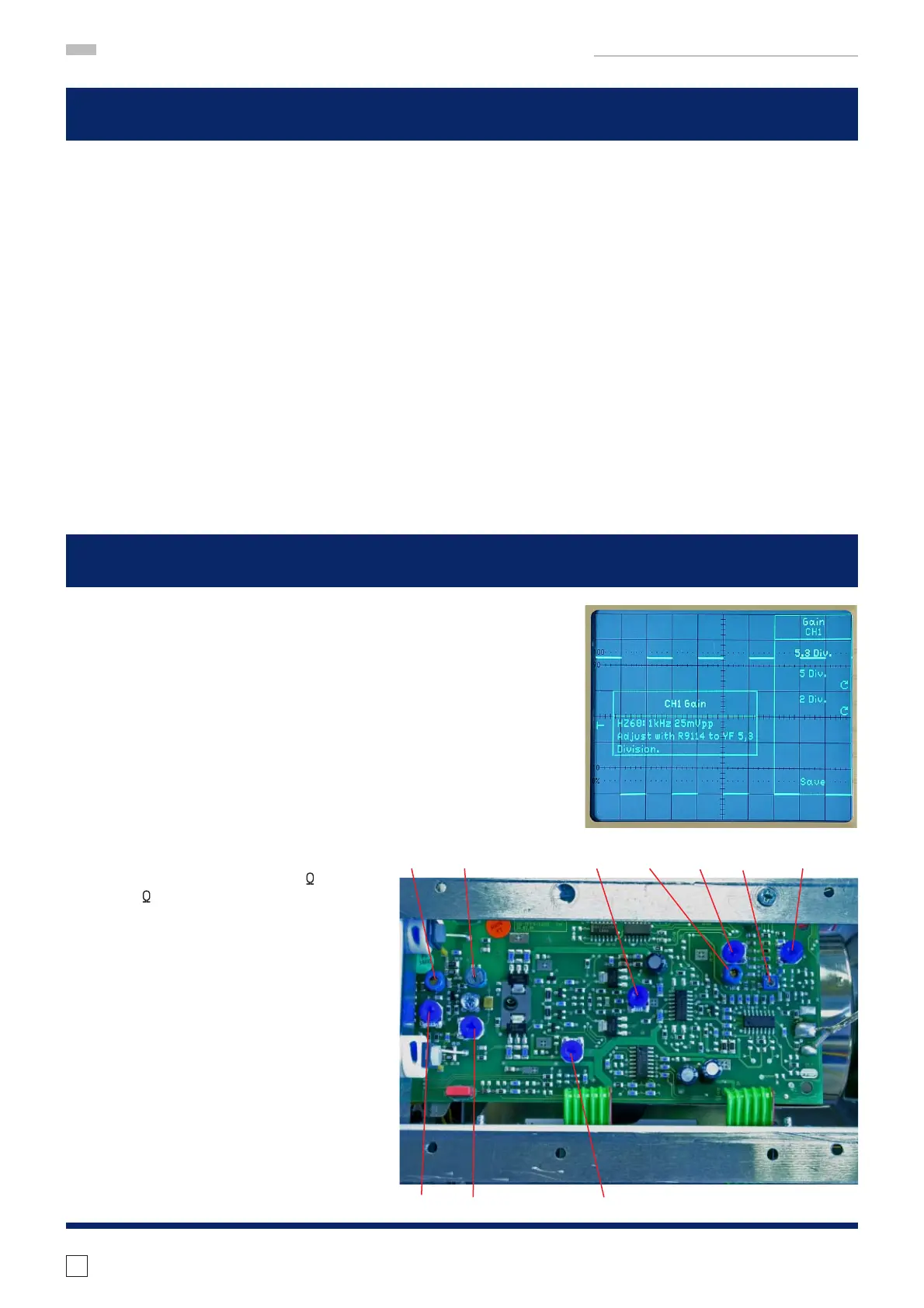

– Locate and identify R9114 on YF-Board.

– Adjust R9114 for 5.3 div signal height.

– Continue with item 26.

R9114

25 YP CH 1 Analog Gain

24 Readout Adjustment (Software Adjustment)

C9001 C9037 R9114 C9045 R9118 C9009 R9149

R9034 R9126 R9057

correct

Loading...

Loading...