MAINTENANCE

9-4 MS 3000 • 9095-032A

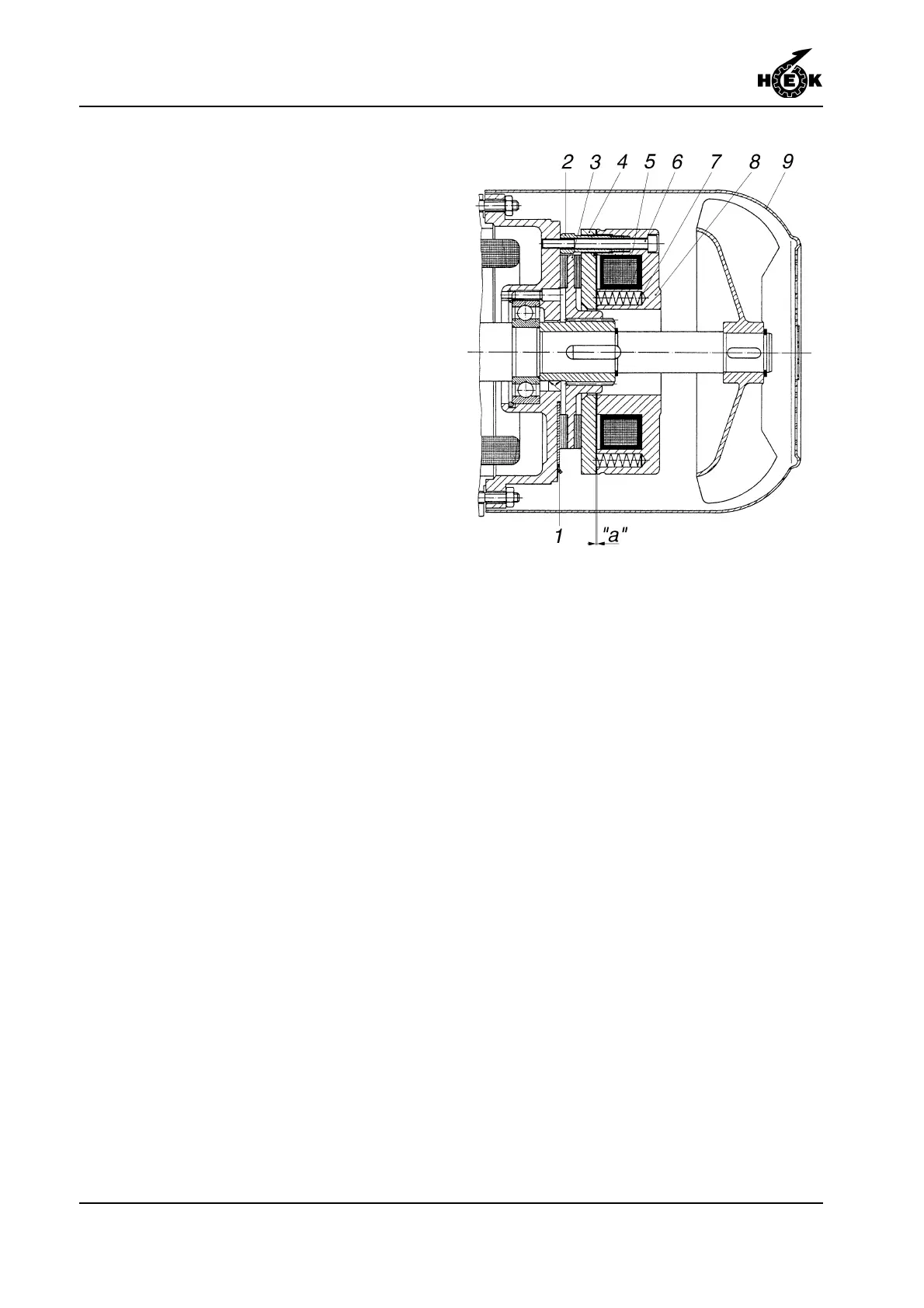

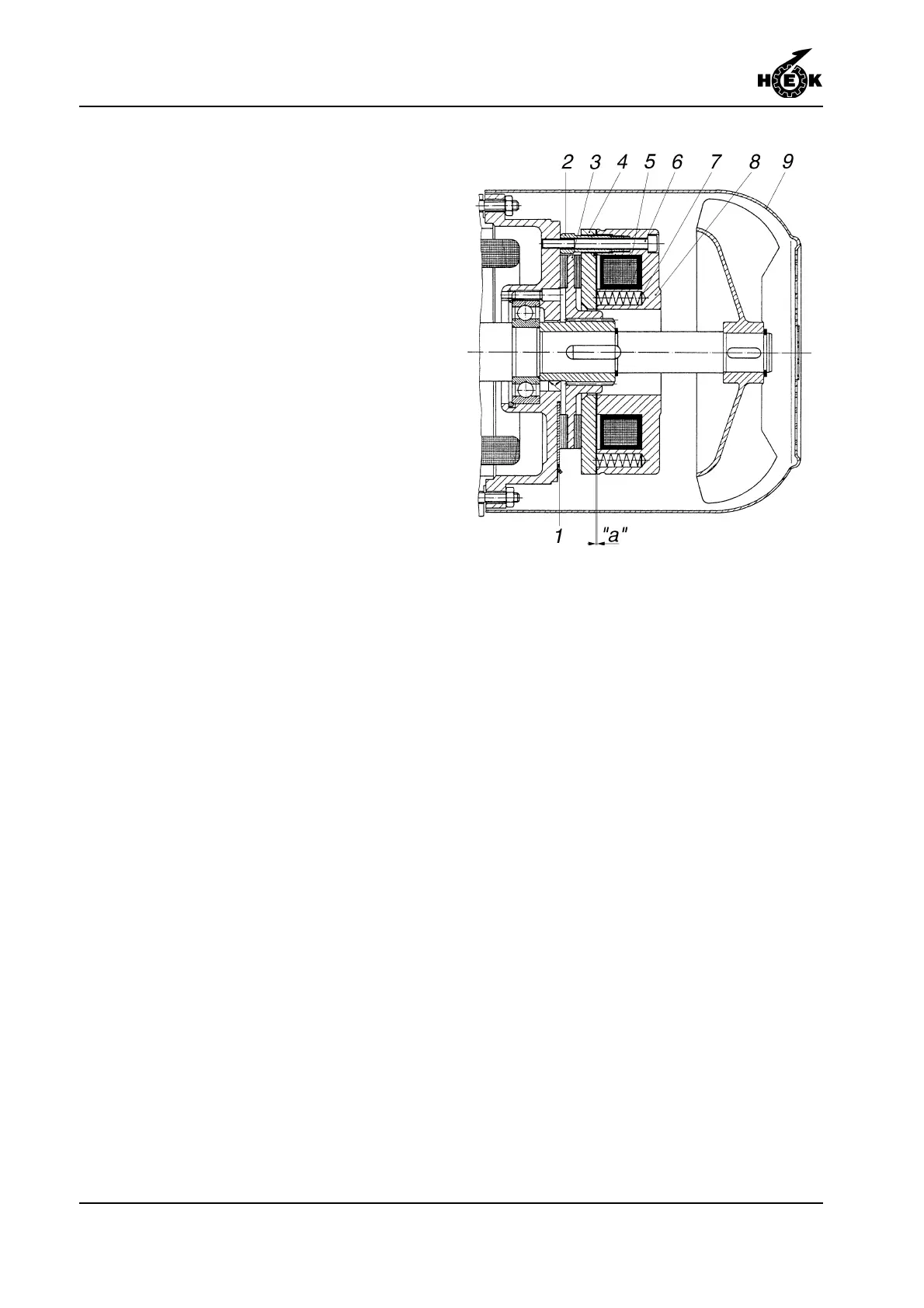

The stator has a built-in braking coil (5)

which produces a strong magnetic field

when a DC current is applied to it.

When the brake is to be released, a

current is made to flow through the braking

coil. The resulting magnetic field "pulls" the

anchor disc toward the stator, thus

releasing the brake.

It is also possible to release the brake

manually. If the manual release lever is

pressed in the direction indicated by the

arrow on the cover, the anchor plate is

moved against the spring pressure with the

aid of two ball bolts, so that it is pressed

towards the stator, releasing the brake.

9.3.2 Maintenance

In normal use the motor brake is more or

less maintenance free. However, after

frequent raising and lowering of the

platform it may be necessary to adjust the

air gap between the anchor disk and the

stator, and if necessary, to replace the

rotor.

In order to check the condition of the brake,

the width of the air gap "a" and the

thickness of the friction material on the

rotor must be measured every three

months.

The air gap "a" is adjusted by the

manufacturer to 0.3 mm and must never be

more than 1.1 mm.

To check:

1. Switch off the mast climbing work

platform at the mainswitch and

secure the switch with the padlock.

Fig.9-1 Motorbrake

Loading...

Loading...