Chapter 9 Inverter Functions

9-7-18

9.7.11 Switching Between Two Motors

How to drive two different motors with different settings?

How to store separate setting configurations for two different motors?

How to change between setting configurations for batch production?

Turn the "2nd-motor control [SET]" for the input terminal function on to change target

parameters. This function makes it possible to switch between different parameter

configurations to control two different types of motors.

The "2nd-motor control is selected [SETM] (60)" output terminal function turns on when the

[SET] function is turned on.

Parameters in the 200s parameter number of function groups A, b, C, and H are the second

control parameters.

(Example) The second control parameter corresponding to the "Frequency input source selection,

1st-motor [A001]" is the "Frequency input source selection, 2nd-motor [A201]".

These parameters do not change, even when changing [SET] during inverter operation. In this

case, parameters change after the output is cut off.

Please allow at least one second for changes to occur if you want to switch the [SET] terminal

and immediately run operations.

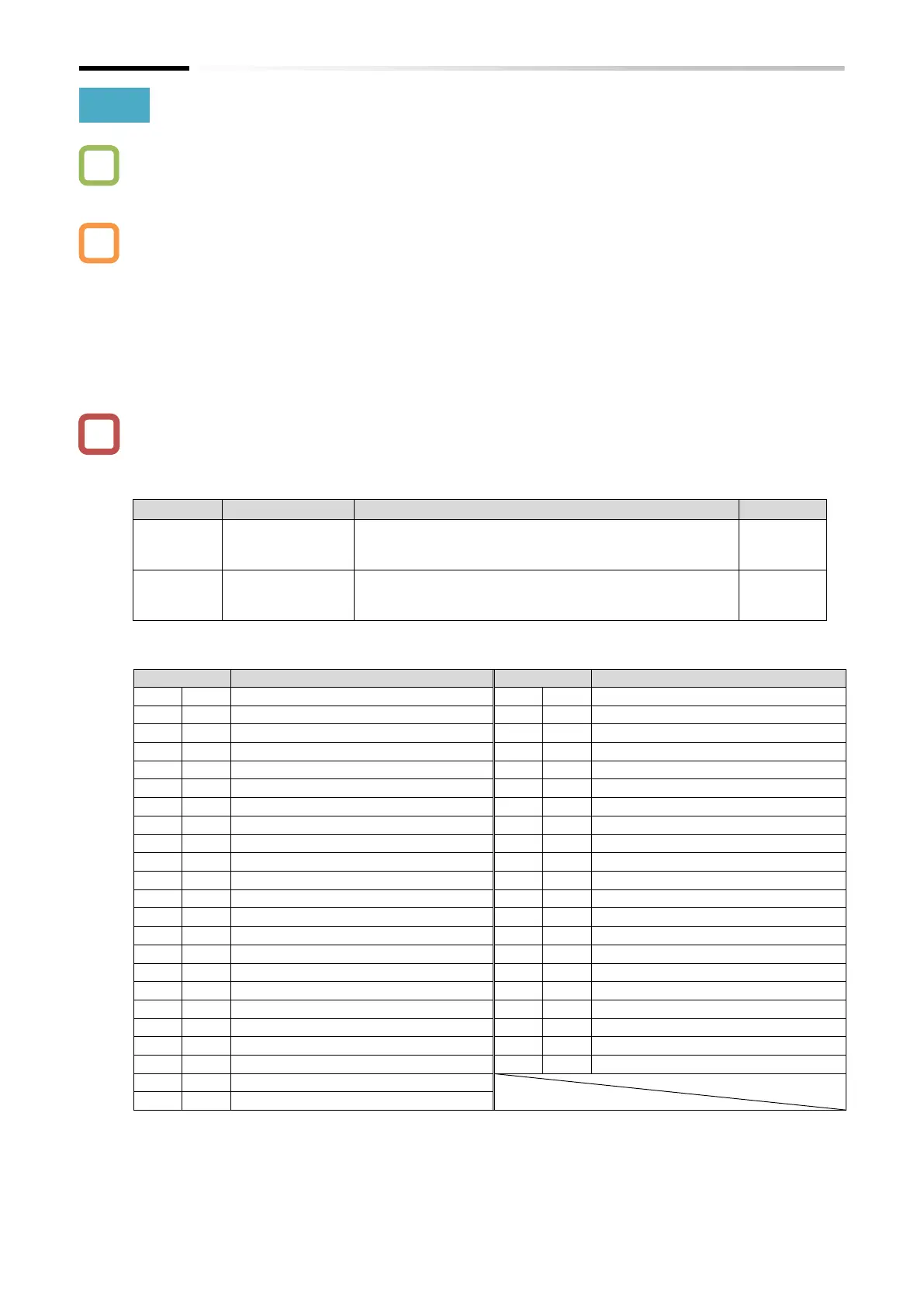

2nd-motor control [SET]:

Turn this function on to switch to the second control

parameter.

2nd-motor control is selected [SETM]:

After [SET] is turned on, switching to the second

control parameter turns this signal on.

◼ List of parameters switched by turning [SET] on/off

Acceleration time 1 setting or monitor

Deceleration time 1 setting or monitor

Electronic thermal characteristics selection

Frequency input source selection

Overload restriction 1 mode selection

RUN command input source selection

Overload restriction 1 active level

Overload restriction 1 action time

Async. Motor constant selection

Torque boost mode selection

Manual torque boost value

Async. Motor number of poles

Manual torque boost peak speed

Async. Motor speed response

Async. Motor stabilization constant

Automatic torque boost voltage compensation gain

Automatic torque boost slip compensation gain

Async. Motor constant R1 (auto-tuning data)

Async. Motor constant R2 (auto-tuning data)

Async. Motor constant L (auto-tuning data)

Async. Motor constant I0 (auto-tuning data)

Accel/Decel change trigger selection

Async. Motor constant J (auto-tuning data)

Accel1 to Accel2 frequency transition point

Decel1 to Decel2 frequency transition point

Loading...

Loading...