Chapter 7 Detailed Function Introduction Shenzhen Hpmont Technology Co., Ltd.

- 36 - HD09-S Series User Manual V1.1

Ref. Code Function Description Setting Range [Default]

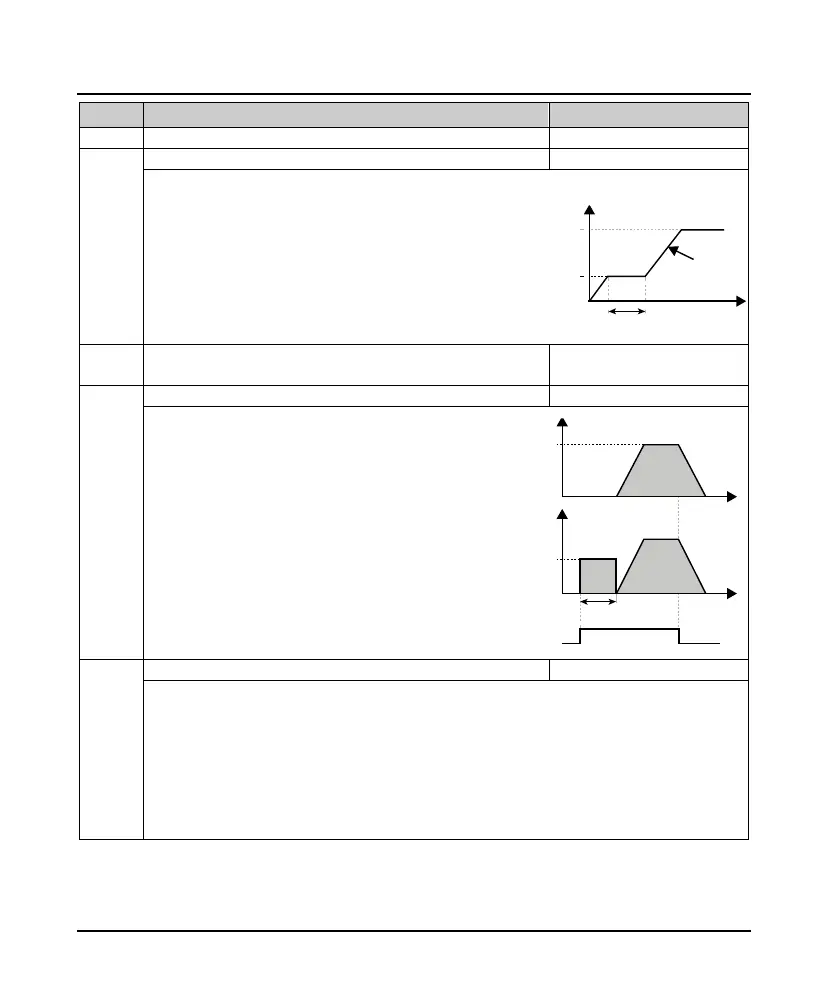

F02.02 Frequency setting of DWELL starting 0.00 - F00.08 [0.00Hz]

Frequency keeping time of DWELL starting

At start-up, the set output frequency is temporarily maintained to prevent the motor from stalling.

For motor-driven load, When a brake is installed, when the brake

moves slowly, use the start-up DWELL function to accelerate

after the brake is fully open to prevent brake friction.

• During Acc., when the setting frequency matches the

frequency set by F02.02, the output frequency is kept

accelerating after the time set in F02.03.

• F02.02 = 0 or F02.03 = 0, DWELL frequency in starting is not

valid.

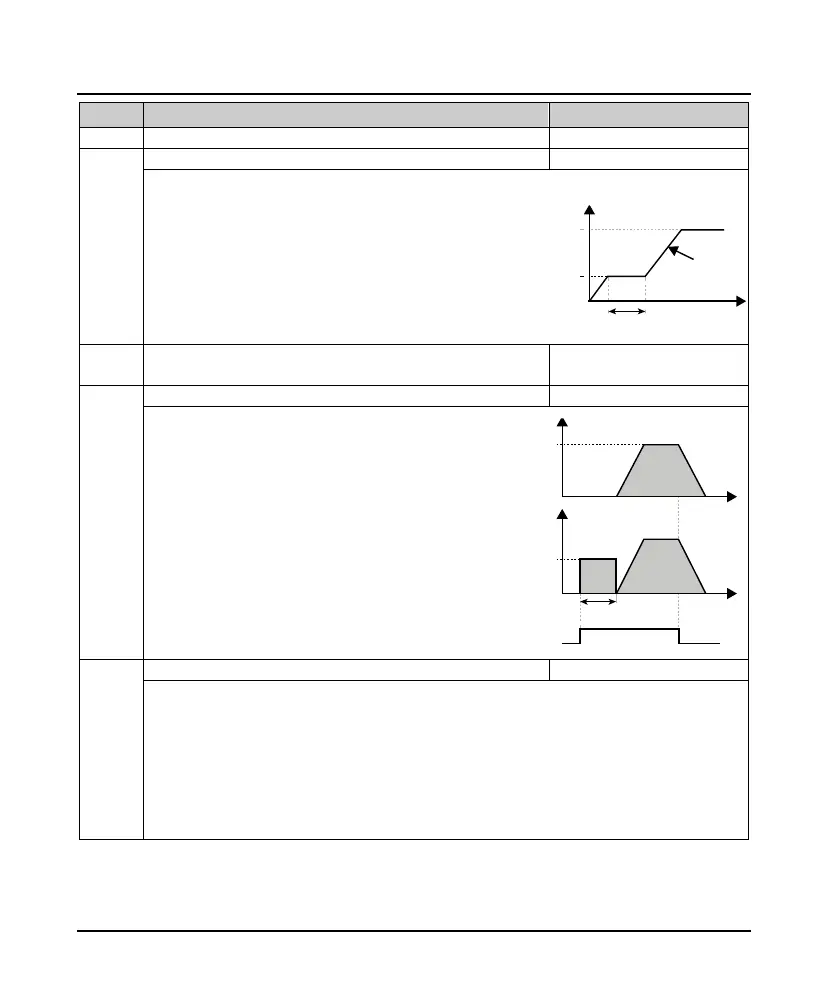

F02.04 DC brake current setting 0 - 100% (inverter rated current)

F02.05 Starting DC braking time 0.00 - 60.00 [0.00s]

F02.04 is the percentage of the inverter's rated

current. Set the DC braking start and stop DC braking

current value.

• If the set DC brake current is more than 5 times the

rated motor current, the injected current is 5 times

the rated motor current.

• DC braking current is valid for both DC braking and

DC braking.

F02.05 = 0, no DC braking procedure.

• F02.05 is valid only when F02.00 = 1.

F02.13 Stoping mode selection 0 - 2 [2]

0: Reserved.

1: Stop freely.

• After the inverter receives the stop command, the output will be terminated immediately. The load will

stop freely according to the mechanical inertia.

2: Dec. stop + DC brake.

• After the inverter receives the stop command, it will decrease the output frequency according to the Dec.

time. When the frequency set by F02.16 is reached, DC braking will start.

• Stop DC braking function see F02.16 - F02.18. For Dec. time see F03.01 - F03.02.

F02.03

Time

Frequency

Frequency set

Given

frequency

F02.02

Out frequency

Out voltage

(effective value)

Time

Running frequency

Run command

DC braking value

Time

F02.05

Loading...

Loading...