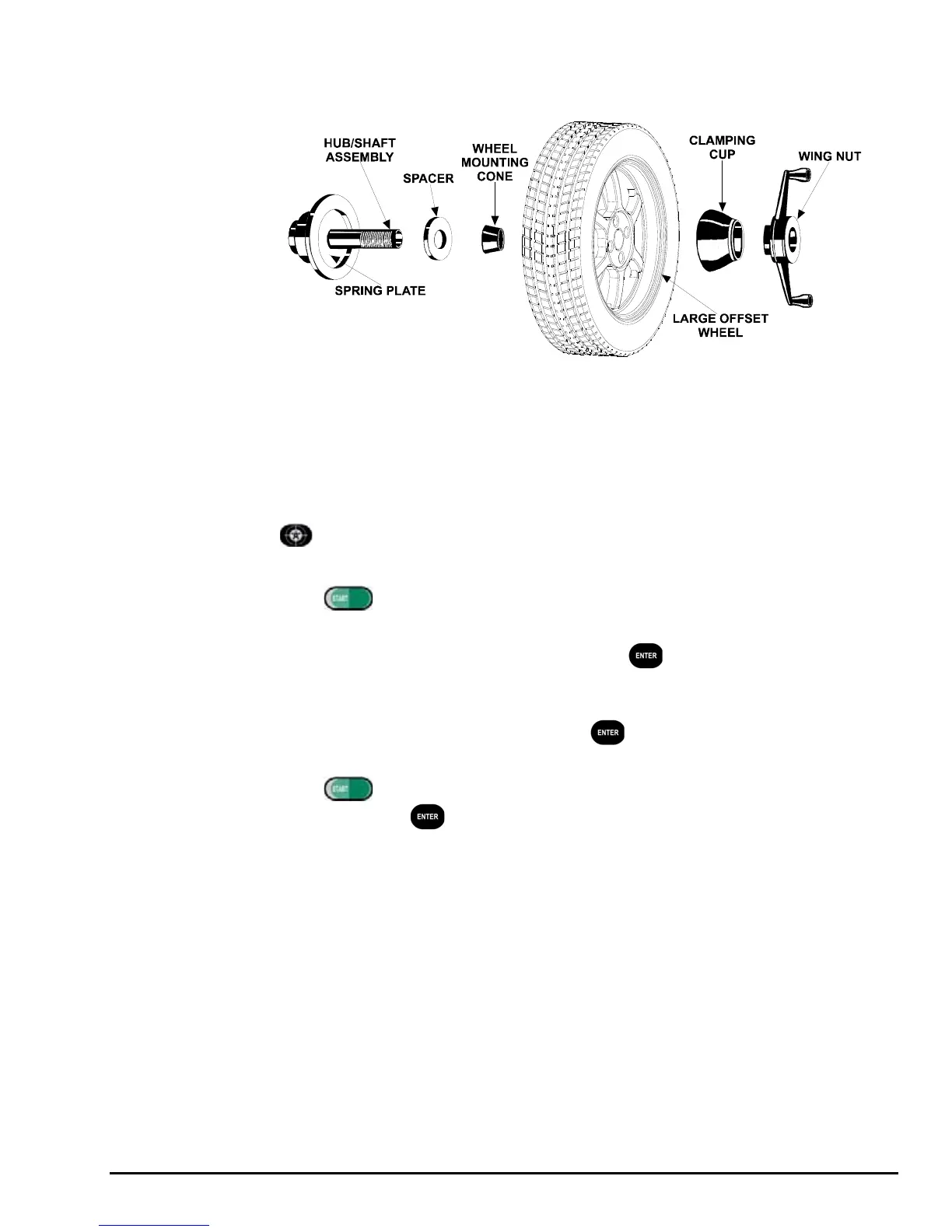

Shaft Spacers

The shaft spacer can be used to make the cone contact the hub bore more firmly.

For example, one cone size is too small because the captivated spring is not

pressing the cone against the inner wheel opening, but the next larger cone size is

too large and will not fit the opening. Use the smaller cone size, with the spacer, to

extend the captivated spring and hold the smaller mounting cone against the wheel

opening with greater pressure.

CenteringCheck

®

After mounting the wheel on the spindle and securing with the wing nut, press the

“CenteringCheck

®

” button.

Display shows “Rdy” “Spn.”

Press

“Start” or lower hood to spin. When spin ends, display shows “Put”

“Top,” and valve stem flashes.

Rotate wheel until valve stem is at TDC and press

“Enter” or step on foot pedal.

Display shows “rot” “180.”

Step on foot pedal to lock spindle. Loosen wing nut and rotate wheel and adaptors

about 180 degrees. Tighten wing nut. (Press

“Enter” if no foot pedal.) Display

shows “Rdy” “Spn.”

Press

“Start” or lower hood. When spin ends, rotate wheel until valve stem is

at TDC, and press

“Enter” or step on foot pedal.

If centering of the assembly repeats balance weight magnitude and phase angle to

within programmed limits, the assembly is assumed to be centered. The display

momentarily flashes “PASS,” then shows correction weights.

If centering of the assembly does not repeat balance weight magnitude and phase

angle to within programmed limits, the assembly is likely not centered. The display

momentarily flashes “FAIL” then shows “---” instead of weights. Check wheel to

adaptor fitment and centering. Retry.

DSP9200 Series Balancer Operation Instructions 3. Balancing a Wheel

25

Loading...

Loading...