OperatiOn

4-50 HPR130XD Auto Gas – 806330 Revision 2

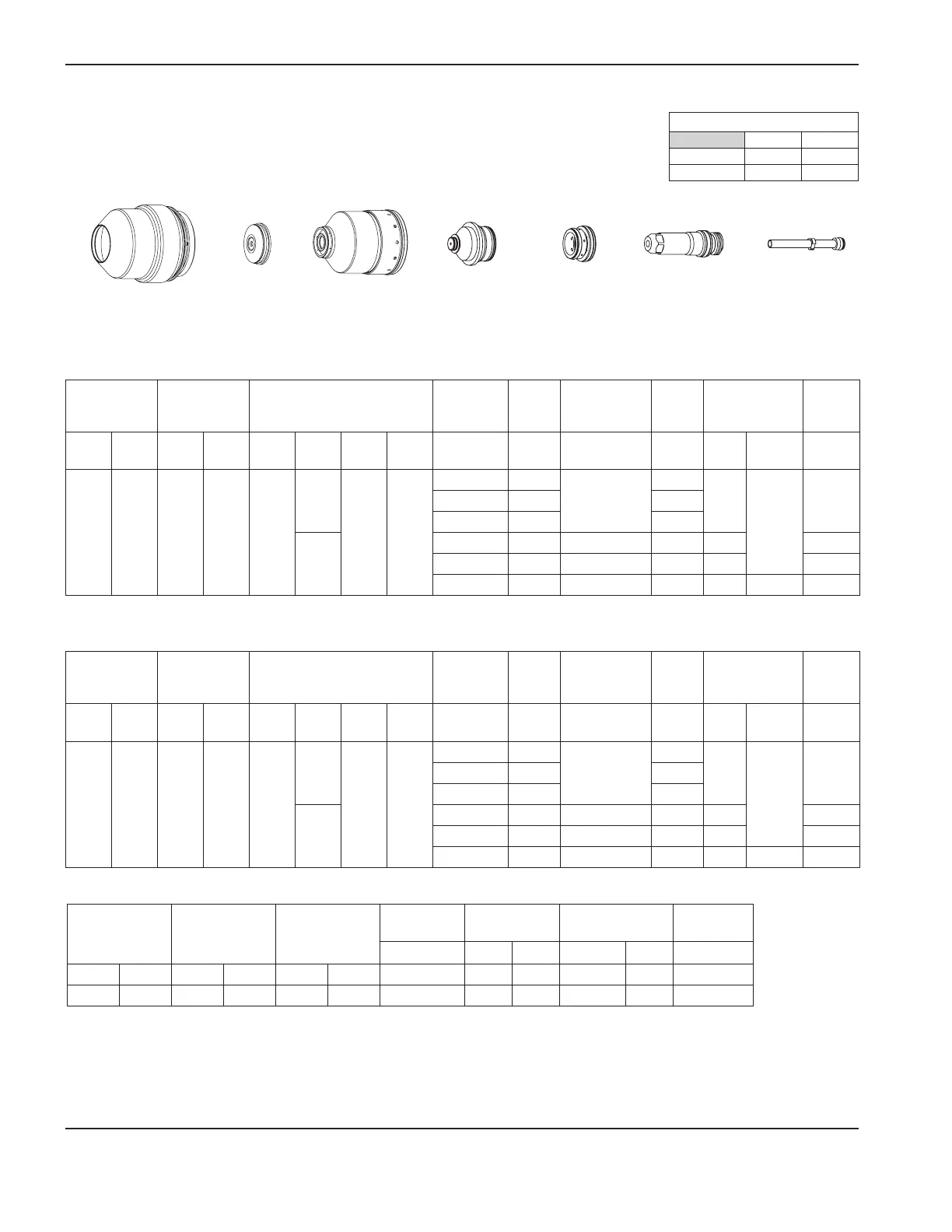

Stainless steel

H35 and N

2

Plasma / N

2

Shield

130 A

Note: This process produces a smoother, shinier cut edge with less dross, and the cut edges are less

perpendicular than the 130 A, N

2

/N

2

process. Edge color is more silver than the H35/N

2

process.

Metric

English

Select

Gases

Set

Preflow

Set

Cutflow

Material

Thickness

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Mix

Gas 1

Mix

Gas 2

mm Volts mm mm/m mm Factor % Seconds

H35 N

2

19 51 75

38

32 18

6 150

3.0

1835

6.0

200

0.38 152 1515

10 153 1195

27

12 160 3.5 875 7.0 0.5

15 168 3.8 670 7.6 0.8

20 176 4.3 305 7.7 180 1.3

Select

Gases

Set

Preflow

Set

Cutflow

Material

Thickness

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Mix

Gas 1

Mix

Gas 2

inches Volts inches ipm inches Factor % Seconds

H35 N

2

19 51 75

38

32 18

1/4 150

0.12

70

0.24

200

0.35/16 152 60

3/8 153 50

27

1/2 160 0.14 30 0.28 0.5

5/8 168 0.15 25 0.30 0.8

3/4 176 0.17 15 0.31 180 1.3

Marking

Flow rates – lpm/scfh

H35 N

2

Preflow 0 / 0 97 / 205

Cutflow 13 / 28 71 / 150

Select

Gases

Set

Preflow

Set

Cutflow

Amperage

Torch-to-Work

Distance

Marking

Speed

Arc

Voltage

A mm inches mm/m ipm Volts

N

2

N

2

10 10 10 10 18 2.5 0.10 6350 250 130

Ar N

2

50 10 50 10 15 3.0 0.12 2540 100 75

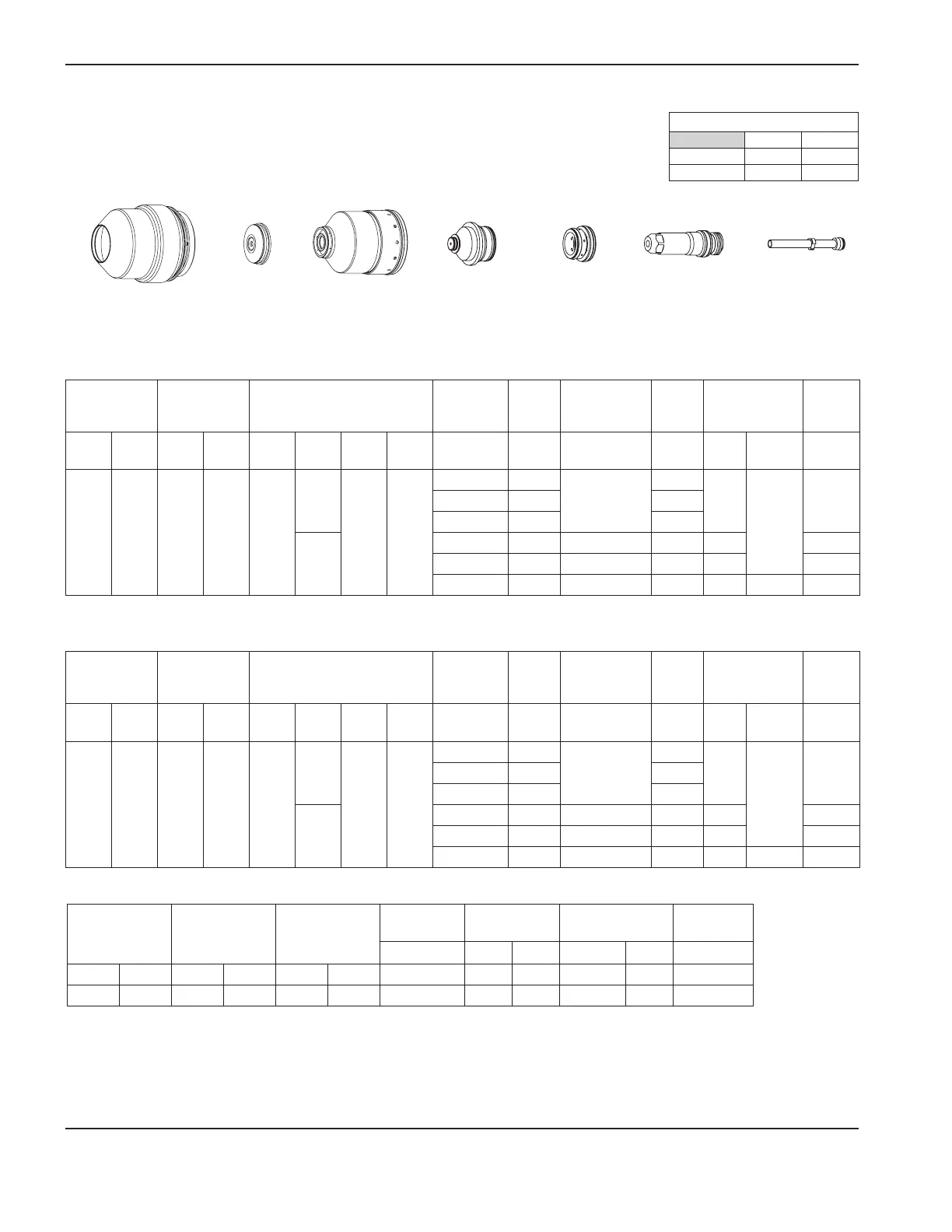

220198 220307

220179

220197220755220747 220340

Loading...

Loading...