41

Principles of Operation

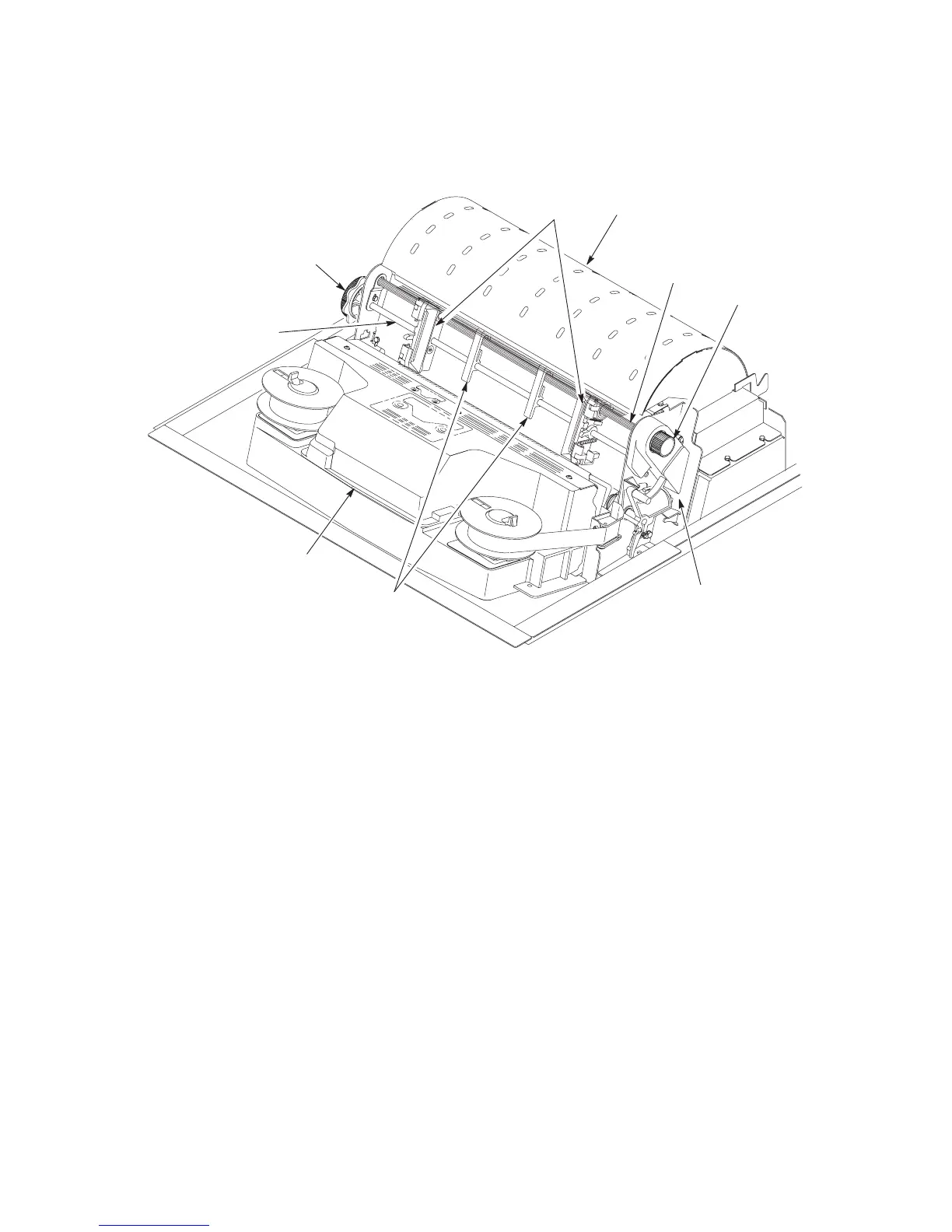

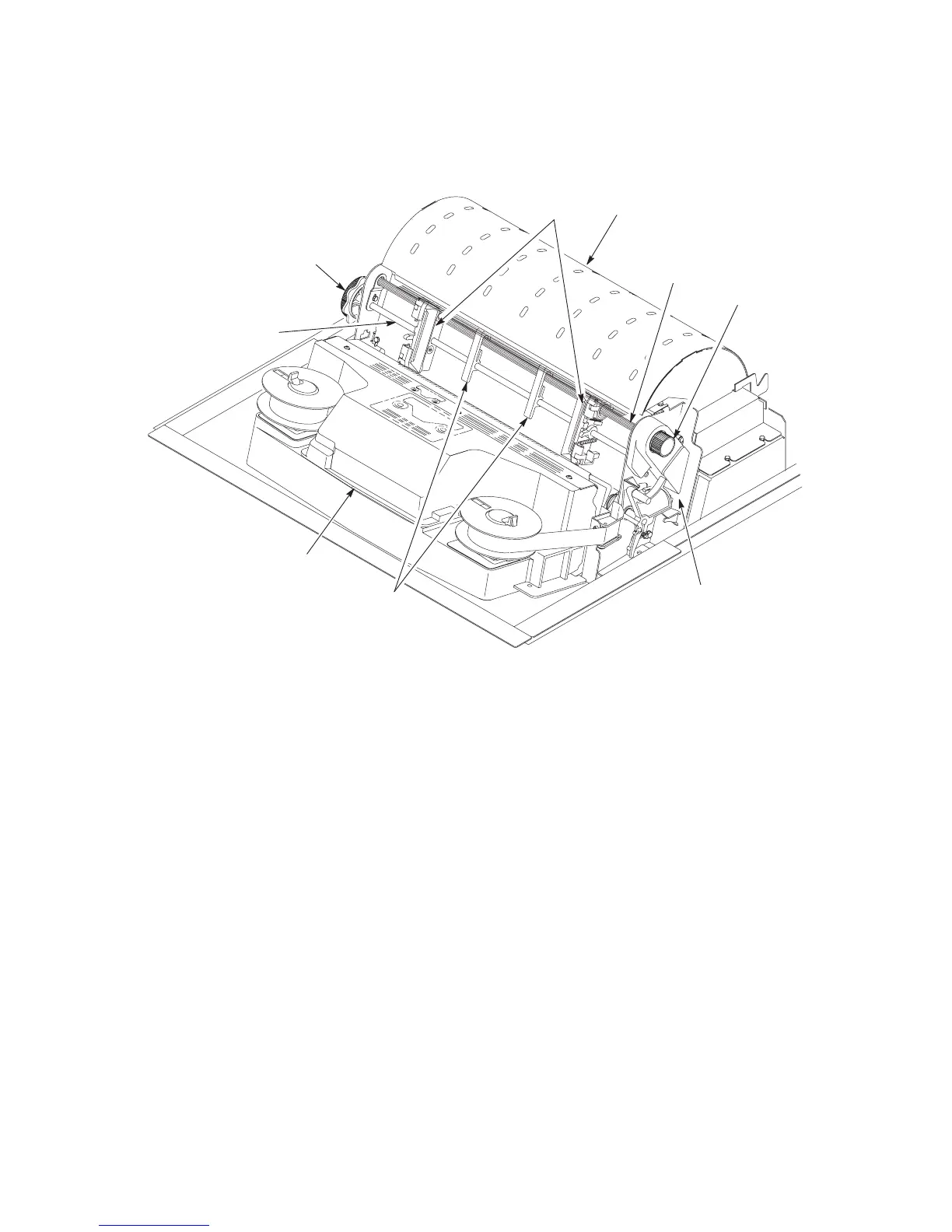

Paper Transport System

Tractors

Vertical Adjustment

Knob and Splined

Shaft Pulley

Paper Feed Timing

Belt (Under the cover)

Splined

Shaft

Shuttle Cover

Assembly

Tractor

Support

Shaft

Horizontal

Adjustment

Knob

Paper Path

Paper

Supports

Figure 13. Paper Transport System

A two-phase DC stepper motor, directed by the EC on the controller board,

drives two tractor sprockets by means of a toothed belt and splined shaft

pulley arrangement. The stepper motor permits extremely accurate

incremental vertical paper movement. This drive configuration is designed for

continuous, fan-folded paper three to 17 inches wide and one to six sheets

thick. For reverse paper feeding, the platen open motor opens and closes the

platen via a toothed belt. Opening the platen prevents paper jams when

paper direction is reversed—that is, paper is moved downwards—in order to

view the print area, set top of form, or allow applications to overprint forms.

Paper is positioned horizontally using the tractors and the horizontal

adjustment knob. Each tractor engages paper perforations with six sprocket

pins and locks in place with a friction lock. The horizontal adjustment knob

allows vernier positioning of the left print margin.

Paper can be positioned vertically by hand with the vertical adjustment knob.

Loading...

Loading...