46

SERVICING (Only to be carried out by Icam trained service engineers)

Ensure that all relevant site personnel & supervising authorities have been informed and, where necessary, the system has been isolated from the main building alarm system before

undertaking any actions which may result in Alarm and/or Trouble/Fault conditions.

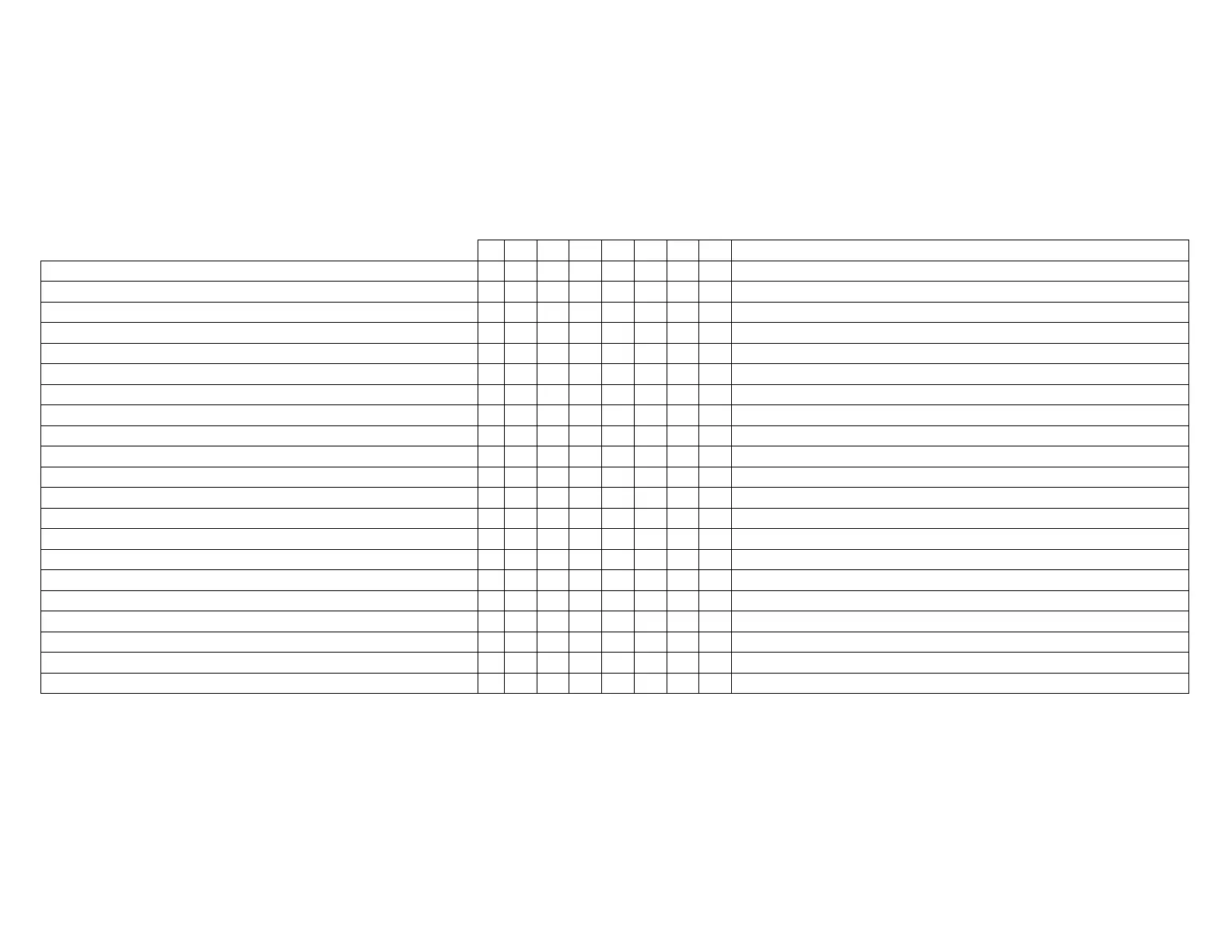

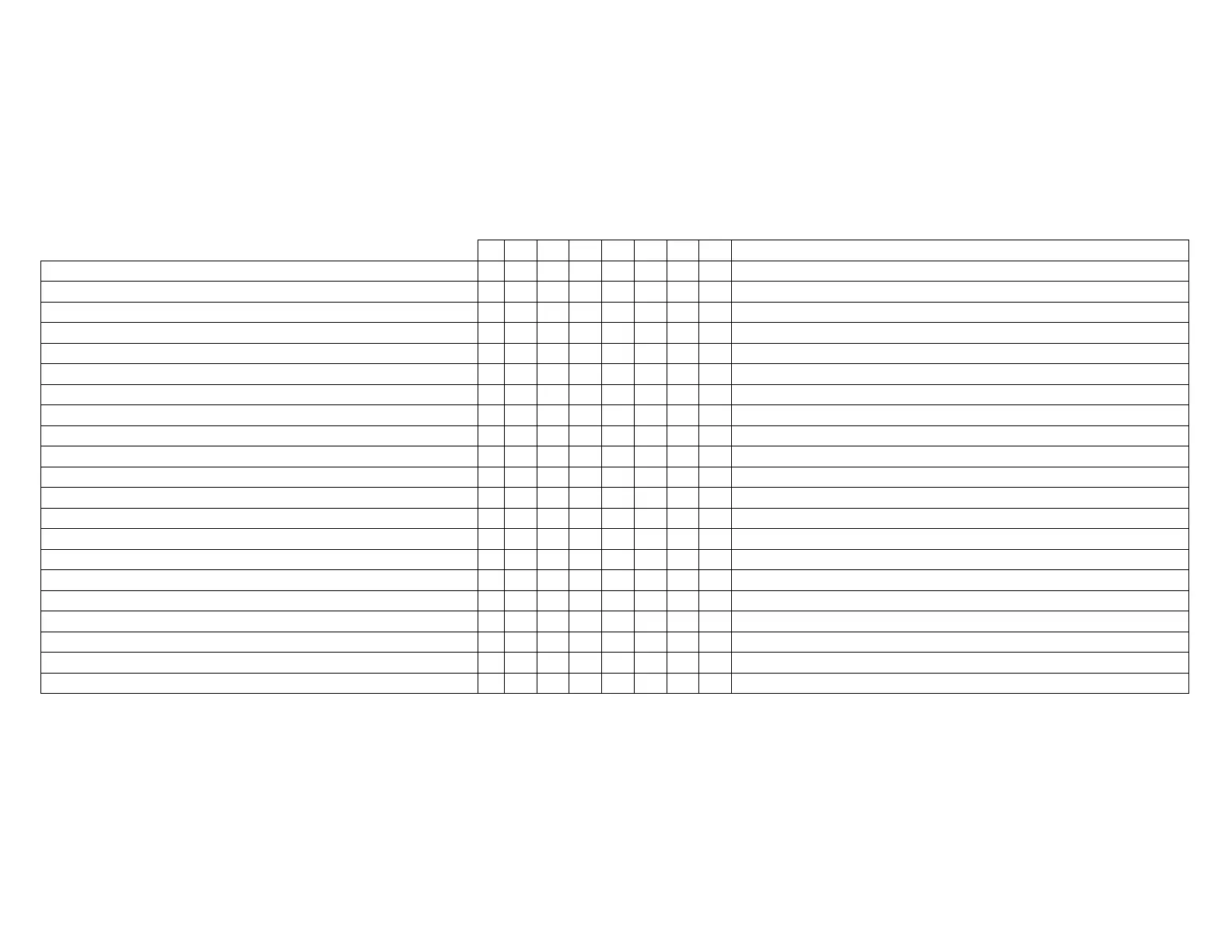

Servicing Interval (Months) > 6 12 18 24 30 36 42 48 NOTES

Check control panel for faults and test LED's X X X X X X X X Not Pico or 'Blind' unit

Check data logs & record main events (Faults/Alarms etc.) X X X X X X X X

Check flow readings and record values for each channel X X X X X X X X

Physically inspect installation (Pipework & Cabling) X X X X X X X X

Inspect fuses and ensure correct ratings X X X X X X X X

Replace detector filter elements & clean chamber* X X X X X X X X

Replace internal filters* X X X X X X X X

Inspect and clean/replace in-line & end of line filters* X X X X X X X X

Replace Gaswitch Seals (Exchange unit) X X FT 4, 6, 8 & 15 ONLY

Replace pump vanes/rotor (Exchange unit) X X FT 8 & 15 ONLY

Replace exhaust filter/silencer & associated tubing X X FT 8 & 15 ONLY

Normalise flow X X X X X X X X

Record flow values for each channel X X X X X X X X

Test lead acid backup batteries and charger X X X X X X X Mains powered units ONLY

Replace lead acid backup batteries & test charger X Mains powered units ONLY

Replace Lithium data backup battery X

Test optional accessories etc. X X X X X X X X e.g. Remote Display, Relays etc.

Carry out smoke test to BS6266 A.3 on single point X X X X

Carry out smoke test to BS6266 A.3 on all channels X X X X

Record results in system log book X X X X X X X X

Complete servicing certificate and issue to user X X X X X X X X

*Cleaning & filter change intervals are dependant on environmental conditions. The above recommendations are based on typical office environments and may need to be increased

for harsher environments.

Loading...

Loading...