5: S

PECIAL

F

UNCTIONS

5-30 S

MART

AXIS P

RO

/L

ITE

U

SER

'

S

M

ANUAL

FT9Y-B1378

Example program 2

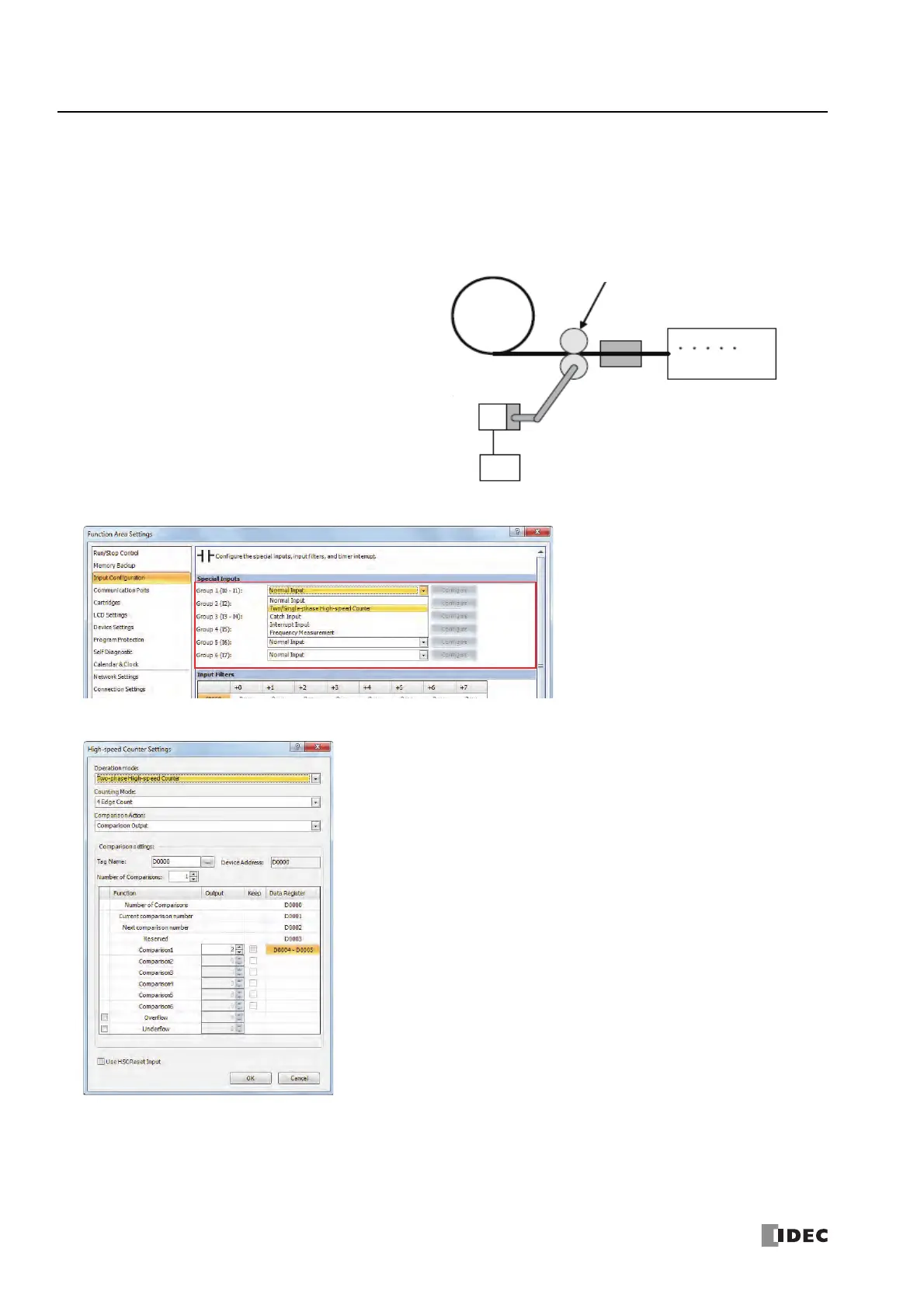

Using the two-phase high-speed counter, the pulses from a rotary encoder are input to the SmartAXIS and a continuous

workpiece is marked at a regular interval.

Application description

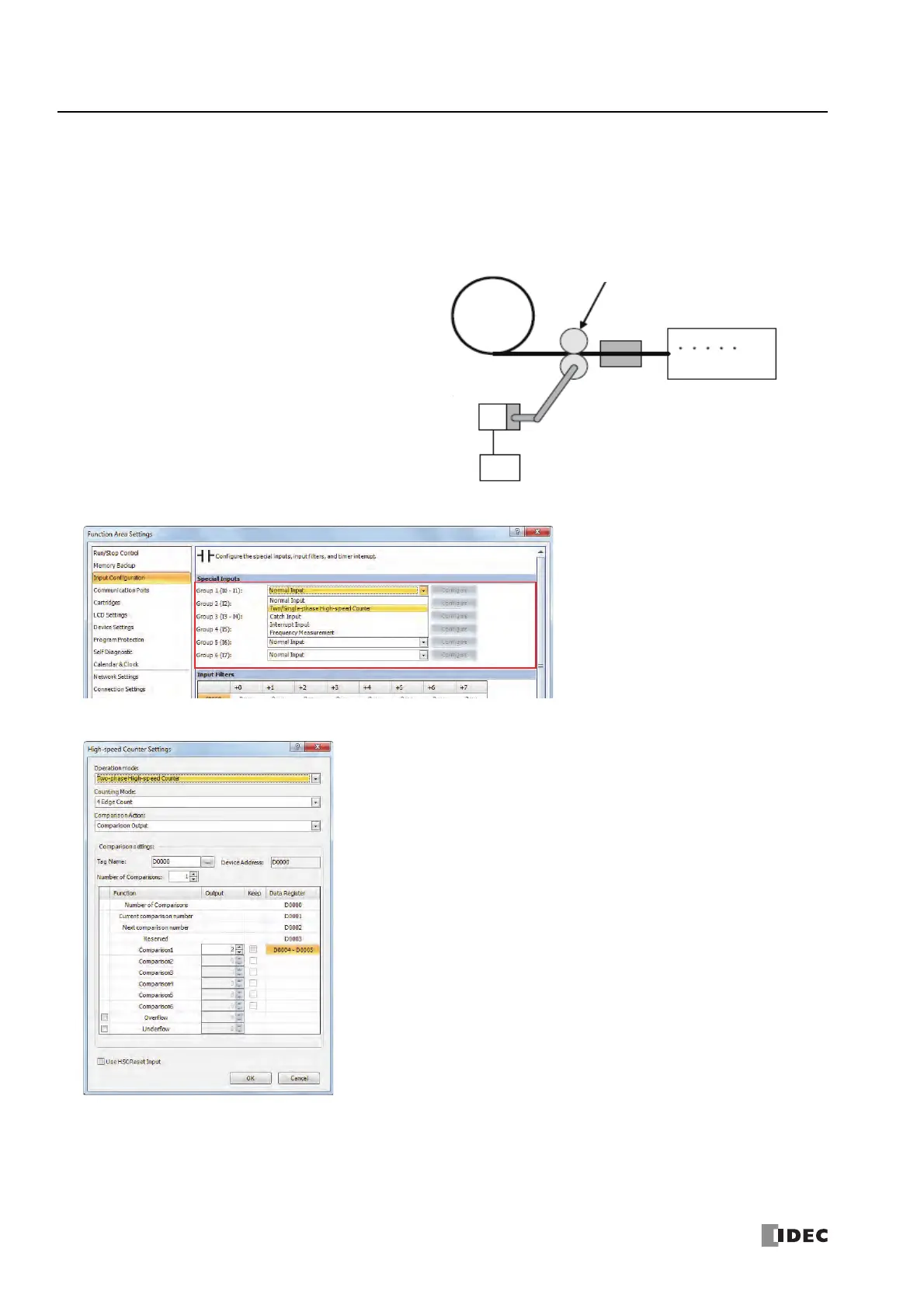

In WindLDR Function Area Settings, select Two/Single-phase High-speed Counter for Group 1.

In High-speed Counter Settings, configure the settings as follows.

• The rotary encoder pulses are input to external inputs

I0 and I1. A continuous sheet of paper is marked

(holes are punched) at a regular interval (every 2,700

pulses).

• The rotary encoder is directly connected to the paper

feed roller, and output pulses are counted by the

high-speed counter and controlled.

• The cycle time is the time to count 2,700 pulses.

When the hole punch time is 0.5 seconds, the

operation condition is 2,700 pulse count time > 0.5

seconds.

Paper roll

Paper feed roller

Perforator

Rotary encoder

SmartAXIS

External input : Group 1 (I0 to I1)

Operation mode : Two-phase High-speed Counter

Counting Mode : 4-edge Count

Comparison Action : Comparison Output

Comparison settings

Tag name/device address : D0 (data register)

Number of preset values : 1

Comparison output : Q2 (external output when matched)

Preset value 1 (D4) : 0 (upper word)

Preset value 1 (D5) : 2,700 (lower word)

Keep : Cleared

Reset value (D8054) : 0 (upper word)

Reset value (D8055) : 0 (lower word)

Overflow : Cleared

Underflow : Cleared

Use HSC Reset Input : Cleared

Loading...

Loading...