S

MART

AXIS P

RO

/L

ITE

U

SER

'

S

M

ANUAL

FT9Y-B1378 5-35

5: S

PECIAL

F

UNCTIONS

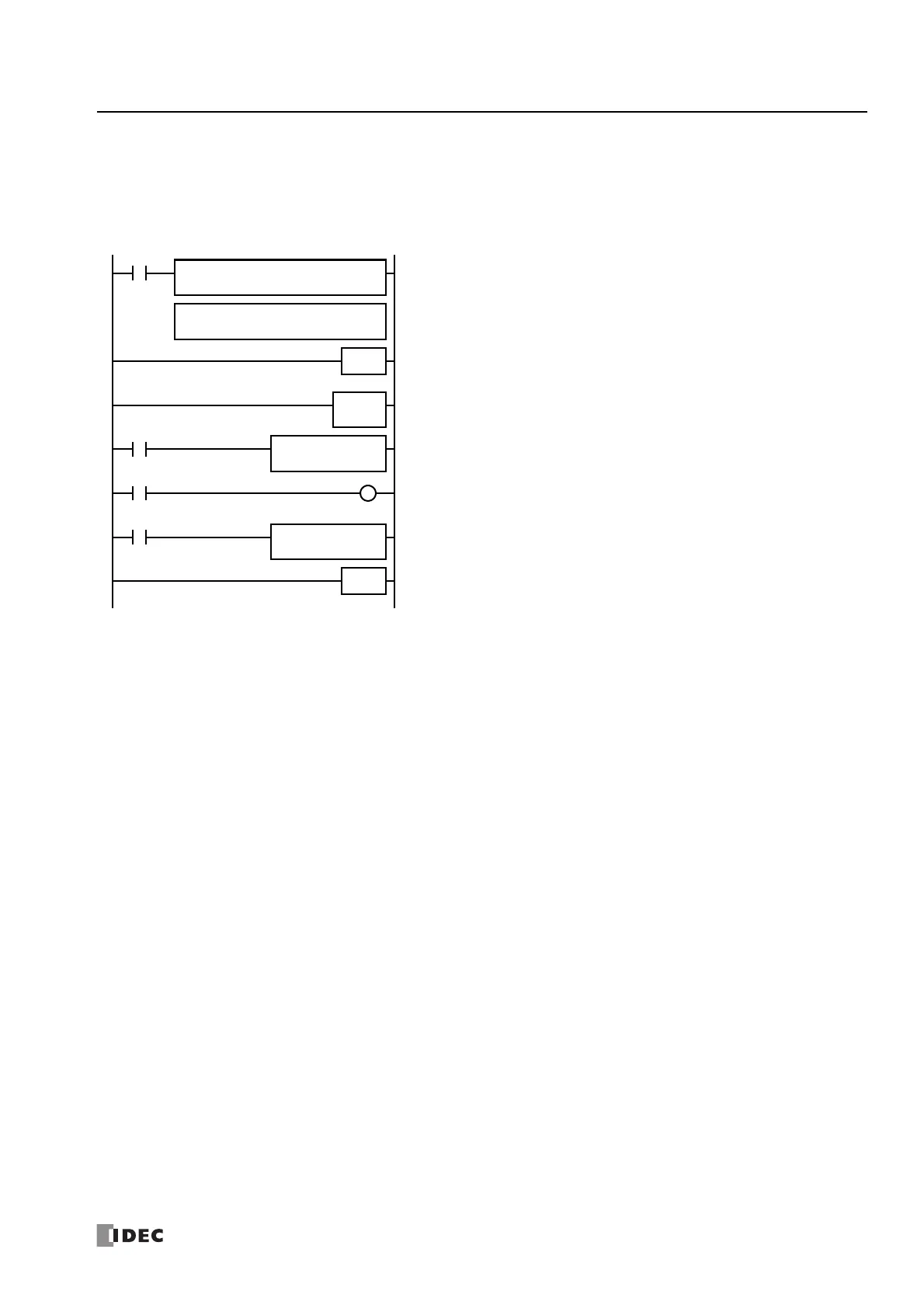

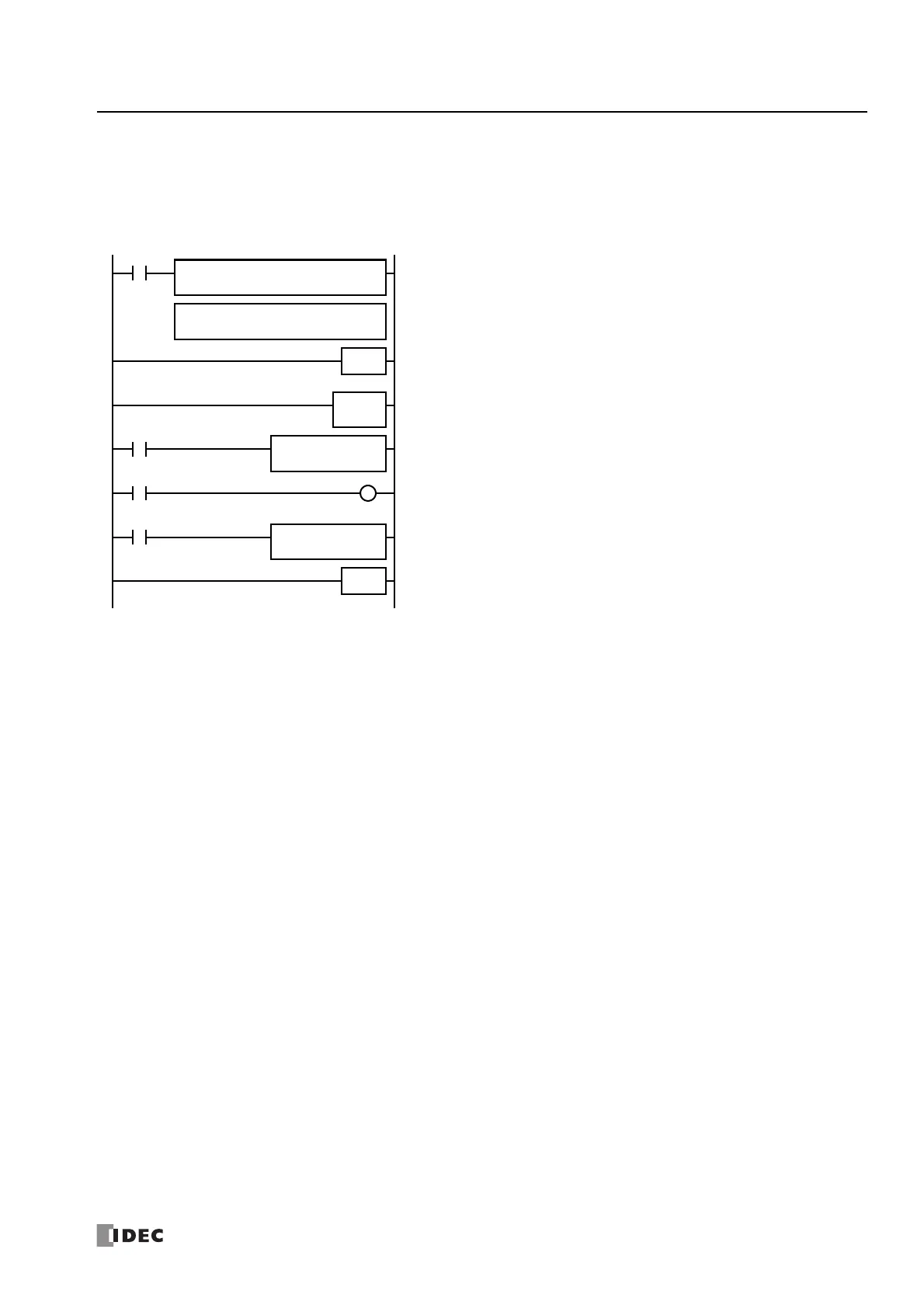

Example: Interrupt Input

The following example demonstrates a program using the interrupt input function, with input I2 designated as an interrupt input.

When the interrupt input is turned on, the input I0 status is immediately transferred to output Q0 using the IOREF (I/O refresh)

instruction before the END instruction is executed. For the IOREF instruction, See Chapter 15 "Refresh Instructions" in the

"SmartAXIS Ladder Programming Manual".

Notes for Using Interrupt Inputs and Timer Interrupt:

• When using an interrupt input or timer interrupt, separate the interrupt program from the main program using the END instruction at the end

of the main program.

• When an interrupt program calls another subroutine, a maximum of 3 subroutine calls can be nested. If more than 3 calls are nested, a user

program execution error occurs, turning on special internal relay M8004 and the ERR LED.

• When using an interrupt input or timer interrupt, include the label number of the interrupt program to be executed when an interrupt occurs.

The label numbers stored in data registers D8032 through D8035, D8037, and D8038 specify the interrupt programs for interrupt inputs I0,

I2, I3, and I5 through I7 and timer interrupt, respectively.

• When more than one interrupt input is turned on at the same time, interrupt program execution is given priority to inputs I0, I2, I3, I5, I6,

and I7, in that order. If an interrupt is initiated while another interrupt program is executed, the subsequent interrupt program is executed

after the prior interrupt is completed. Multiple interrupt programs cannot be executed simultaneously.

• Make sure that the execution time of the interrupt program is shorter than interrupt intervals sufficiently.

• Interrupt programs cannot use the following instructions: SOTU, SOTD, TML, TIM, TMH, TMS, TMLO, TIMO, TMHO, TMSO, CNT, CDP, CUD,

CNTD, CDPD, CUDD, SFR, SFRN, WEEK, YEAR, MSG, DI, EI, XYFS, CVXTY, CVYTX, AVRG, PULS, PWM, RAMP, ZRN, ARAMP, DTML, DTIM,

DTMH, DTMS, TTIM, FIFOF, NDSRC, HOUR, TXD, RXD, ETXD, ERXD, DLOG, and TRACE.

LABEL

0

M8120

END

Main Program

M8125

Q0

REPS1 –

0

D1 –

D8033

MOV(W)

IOREF S1

I0

M300

M8125

IOREF S1

Q0

LRET

M8120 is the initialize pulse special internal relay.

D8033 stores 0 to designate jump destination label 0 for interrupt input I2.

The interrupt program is separated from the main program by the END instruction.

When input I2 is on, program execution jumps to label 0.

M8125 is the in-operation output special internal relay.

IOREF immediately reads input I0 status to internal relay M300.

M300 turns on or off the output Q0 internal memory.

Another IOREF immediately writes the output Q0 internal memory status to actual

output Q0.

Program execution returns to the main program.

Insert LRET at the end of the subroutine to return to the main program.

Loading...

Loading...