75

INSTALLER

USERMAINTENANCE TECHNICIAN

TECHNICAL DATA

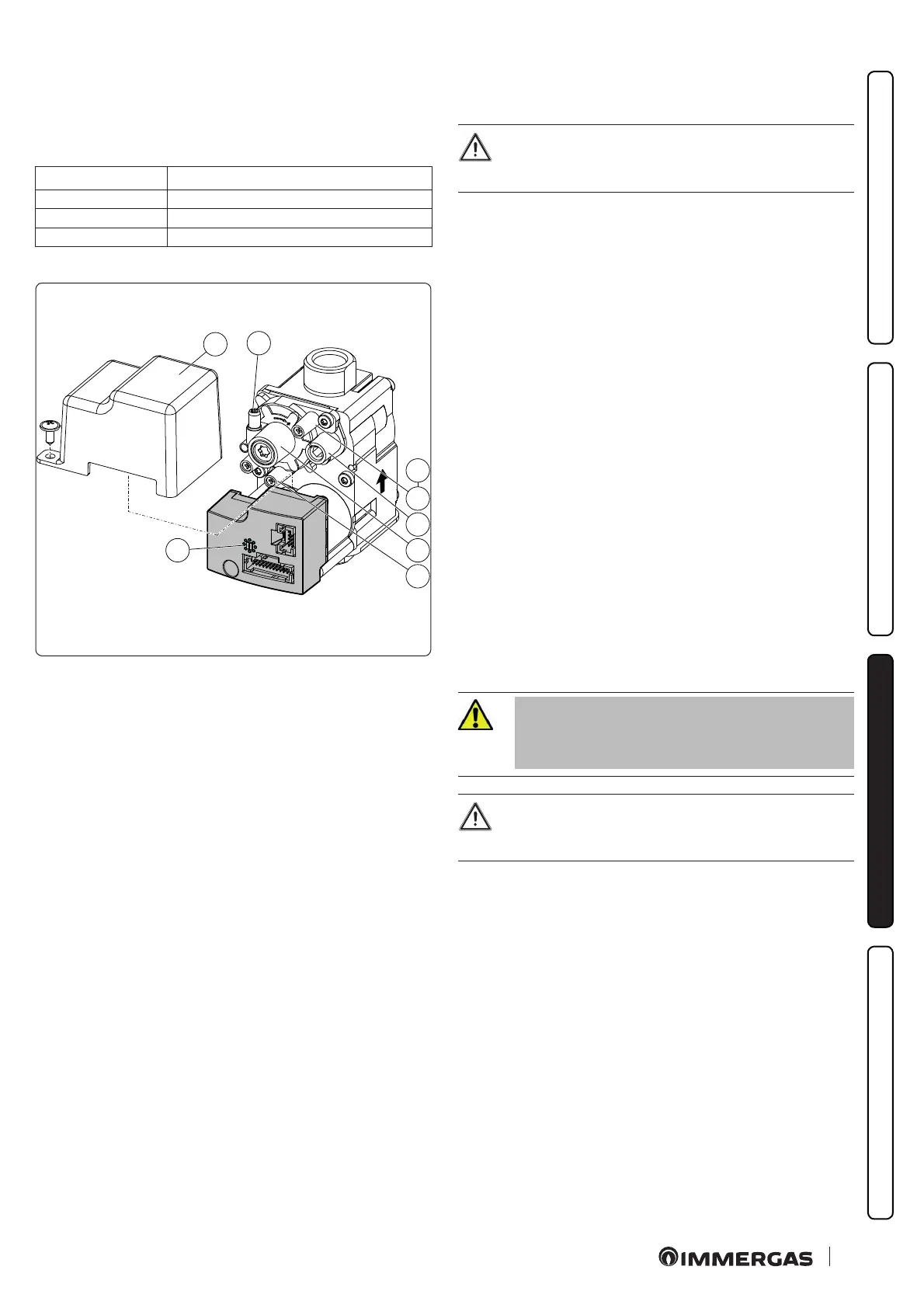

3.9 GAS VALVE

e gas valve (Fig. 65) is equipped with functioning status signal

LED (5), the LEDs are under the transparent protection cover (4).

Colour Status

O Gas valve not powered

Green Gas valve powered and working

Red Gas valve powered and not working

OUT

IN

1

3

P3

2

P1

12

4

5

65

Key (Fig. 65):

1 - Gas valve inlet pressure point

2 - Gas valve outlet pressure point

3 - O/Set adjustment screw

4 - Transparent protection cover

5 - Gas valve status signal display

12 - Outlet gas ow rate adjuster

3.10 CONVERTING THE HEAT GENERATOR

TO OTHER TYPES OF GAS

e gas conversion operation must be carried out by an

authorised company (e.g. Authorised Technical Assis-

tance Service).

If the appliance needs to be converted to a dierent gas type to that

specied on the data plate, request the relative conversion kit for

quick and easy conversion.

To convert to another type of gas the following operations are re-

quired:

- disconnect power to the appliance;

- replace the nozzle positioned between the gas pipe and the air/

gas mixing sleeve, taking care to remove the voltage from the

appliance during this operation;

- re-power the appliance;

- calibrate fan speed (Parag. 3.11);

- adjust the correct air/gas ratio (Parag. 3.12);

• seal the gas ow rate regulation devices (if settings are modi-

ed);

- aer completing the conversion, apply the sticker, contained in

the conversion kit, near the data nameplate. Using an indelible

m a r k e r p e n , d e l e t e t h e d a t a r e l a t i v e t o t h e o l d t y p e o f g a s .

ese adju stments must be made w it h reference to the t y pe of gas

used, following that given in the table in the indoor unit manual.

C h e c k s f o l l o w i n g c o n v e r s i o n t o a n o t h e r t y p e o f g a s .

Aer having made sure that the conversion is complete and that

the calibration has been successful, you must make sure that:

- there is no ame in the combustion chamber;

- the burner ame is not too high or low and that it is stable (does

not detach from burner);

e pressure testers used for calibration

should be perfectly closed and there

should be no leaks from the gas circuit.

Maintenance operations must be carried out by an au-

thorised company (e.g. Authorised Aer-Sales Techni-

cal Assistance Centre).

Loading...

Loading...