76

INSTALLER

USERMAINTENANCE TECHNICIAN

TECHNICAL DATA

3.11 FAN SPEED CALIBRATION

Verication and calibration are necessary, in the case of

transformation to other types of gas, in the extraordi-

nary maintenance phase with replacement of the PCB,

air/gas circuit components or in the case of installations

with ue extraction systems, with horizontal concentric

pipe measuring more than 1 metre.

e indoor unit heat output is correlated to the length of the air

intake and ue exhaust pipes.

is decreases with the increase of pipe length.

e indoor unit leaves the factory adjusted for minimum pipe

length (1m). It is therefore necessary, especially in the case of max-

imum pipe extension, to check the ∆p gas values aer at least 5

minutes of the burner operating at nominal heat output, when the

temperatures of the intake air and exhaust ue gas have stabilised.

Adjust the nominal and minimum output in the domestic hot

water and central heating modes according to the values in the ta-

ble in the indoor unit manual using the dierential manometers

connected to the ∆p gas pressure points (Det. 9-Fig. 47).

Enter the congurations menu and regulate the following param-

eters (Parag. 3.13);

- DHW minimum no. of fan revs “S 00”;

- DHW maximum no. of fan revs “S 01”;

- delete ignition stage "S 02".

Listed below are the default settings featured:

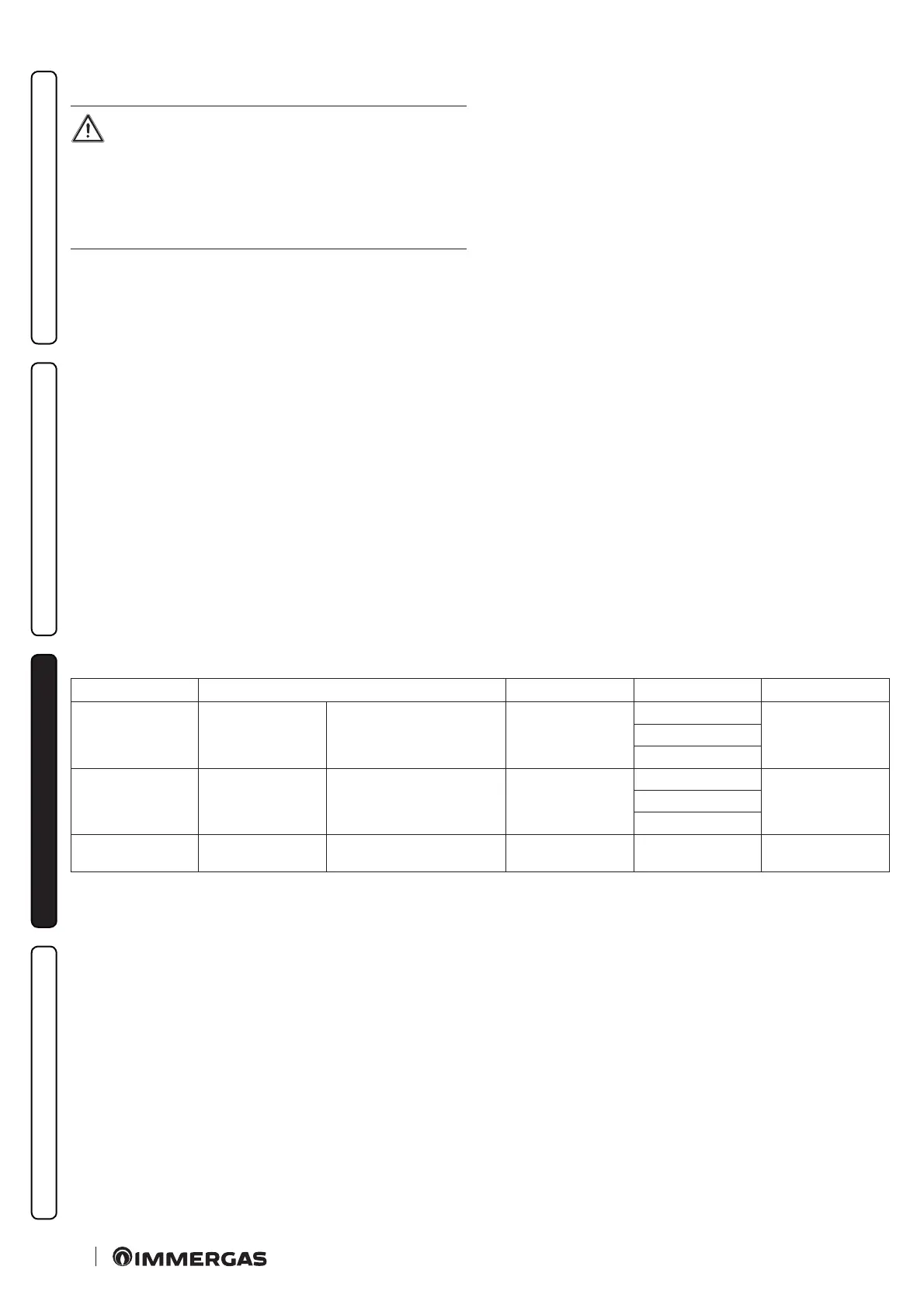

Parameter ID Description Range Default Customised value

S 00

DHW minimum no.

of fan revs

Operating speed of the fan at

minimum DHW output

900 ÷ 1500 (RPM)

G20: 1300

G30: 1300

G31: 1300

S 01

DHW maximum no.

of fan revs

Operating speed of the fan at

maximum DHW output

3000 ÷ 6100 (RPM)

G20: 5100

G30: 4800

G31: 5400

S 02

Ignition phase fan

speed

Operating speed of the fan

during the ignition phase

0 - 100% 16

3.12 ADJUSTMENT OF THE AIRGAS RATIO

Calibration of minimum CO

2

(minimum central heating

output).

Enter the chimney sweep phase without withdrawing domestic

hot water and take the selector switches to minimum until "0" is

seen on the display.

To have an exact value of CO

2

t he tech nic ia n mu st i ns er t t he sa m-

pling probe to the bottom of the sample point, then check that the

CO

2

value is that specied in the table, otherwise adjust the screw

(Det. 3Fig. 65)(O-Set adjuster).

Loading...

Loading...