38

INSTALLER

USERMAINTENANCE TECHNICIAN

TECHNICAL DATA

1.30 WATER TREATMENT PLANT FILLING

As already mentioned in the previous paragraphs, a treatment of

the thermal and domestic system water is required, in compliance

with the local standards in force.

e parameters that inuence the duration and proper operation

of the heat exchanger are the water's PH, total hardness, conduc-

tivity, and oxygen, together with the system's processing residues

(any welding residues), any oil present and corrosion products

that can, in turn, cause damage to the heat exchanger.

In order to prevent this from happening, you are recommended

to:

- clean the system with clean water to eliminate solid residues

before installation on new and old systems;

- clean the system with a chemical treatment:

• clean the new system with a suitable cleaning device (for ex-

ample Sentinel X300, Fernox Cleaner F3 or Jenaqua 300)

combined with thorough washing;

• clean the old system with a suitable cleaning device (for ex-

ample Sentinel X400 or X800, Fernox Cleaner F3 or Jenaqua

4 0 0 ) c o m bi n e d w i t h t h o r ou g h w a s h i n g ;

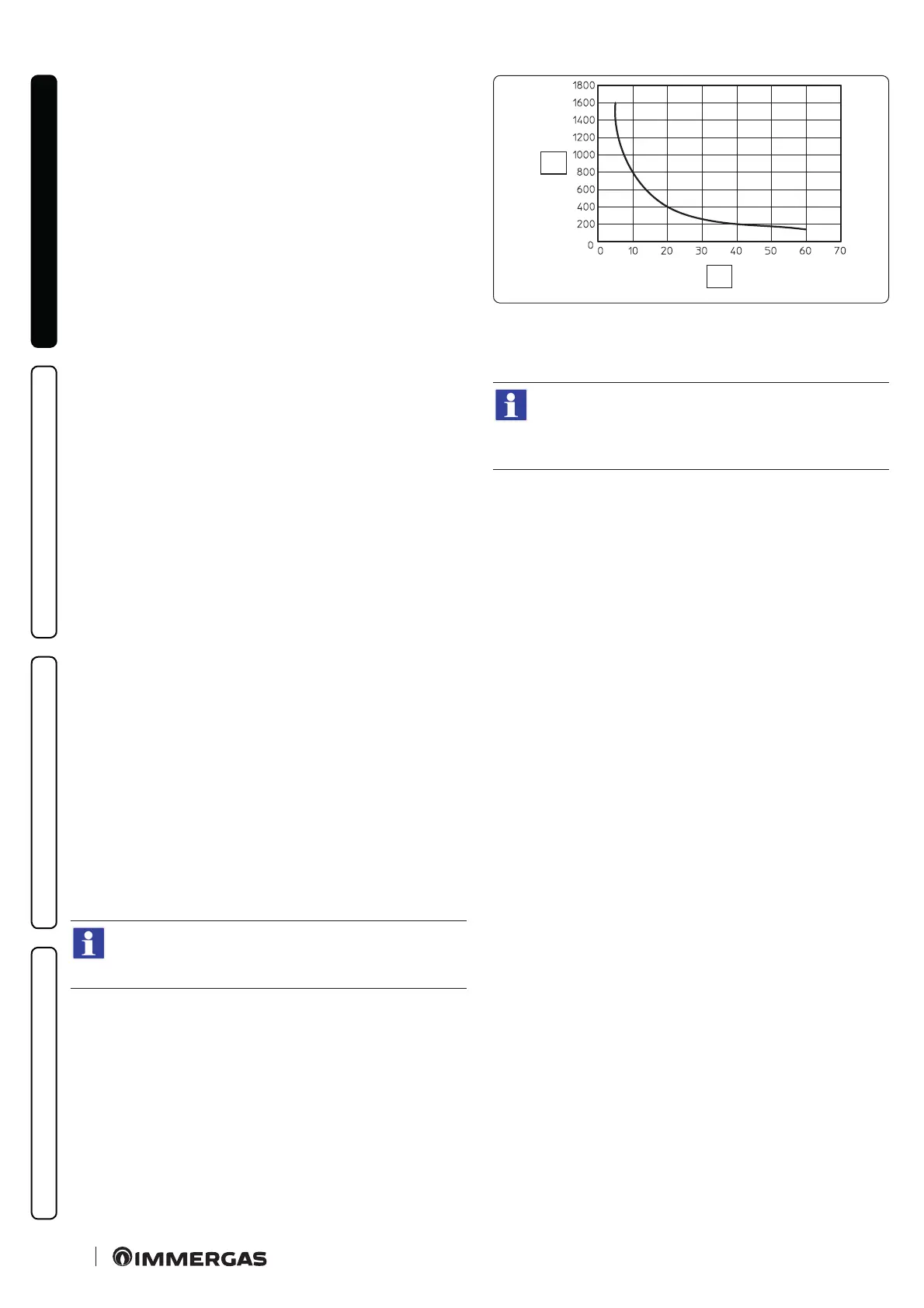

- Check the maximum total hardness and quantity of lling wa-

ter referring to the graphics (Fig. 42); if the contents and hard-

ness of the water are below the indicated curve, no specic treat-

ment is required; otherwise, to limit the content of calcium

carbonate, you must provide for water-lling treatment.

- If it is necessary to provide for water treatment, it should be done

through complete desalination of the lling water. As opposed

to the complete soening process, desalinating the water com-

pletely not only removes hardening agents (Ca, Mg), but also

e l i m i nat e s a l l ot h er m i ne r a l s t o r e du c e w a te r- l l i n g condu c t iv-

ity up to 10 microsiemens/cm. Given its low conductivity, desal-

inated water does not only prevent the formation of lime scale,

but also serves as protection against corrosion.

- Insert a suitable inhibitor / passivator (for example Sentinel

X100, Fernox Protector F1, or Jenaqua 100); if required, also in-

sert appropriate antifreeze (such as for example Sentinel X500,

Fernox Alphi 11 or Jenaqua 500).

- Check electrical conduction of the water, which should be high-

er than 2000 µs/cm in the case of treated water and lower than

600 µs/cm in the case of non-treated water.

- To prevent corrosion, the water system's PH should be between

7.5 and 9.5.

- Check the maximum content of chlorides, which should be less

than 250 mg/l.

For quantities and methods of use of water-treatment

products, refer to the instructions provided by their

manufacturer.

X

Y

42

Key (Fig. 42):

X - Total water hardness °F

Y - Litres of system water

e graph refers to the entire life cycle of the system.

erefore, also consider scheduled and unscheduled

maintenance, which involves emptying and lling the

said system.

Loading...

Loading...