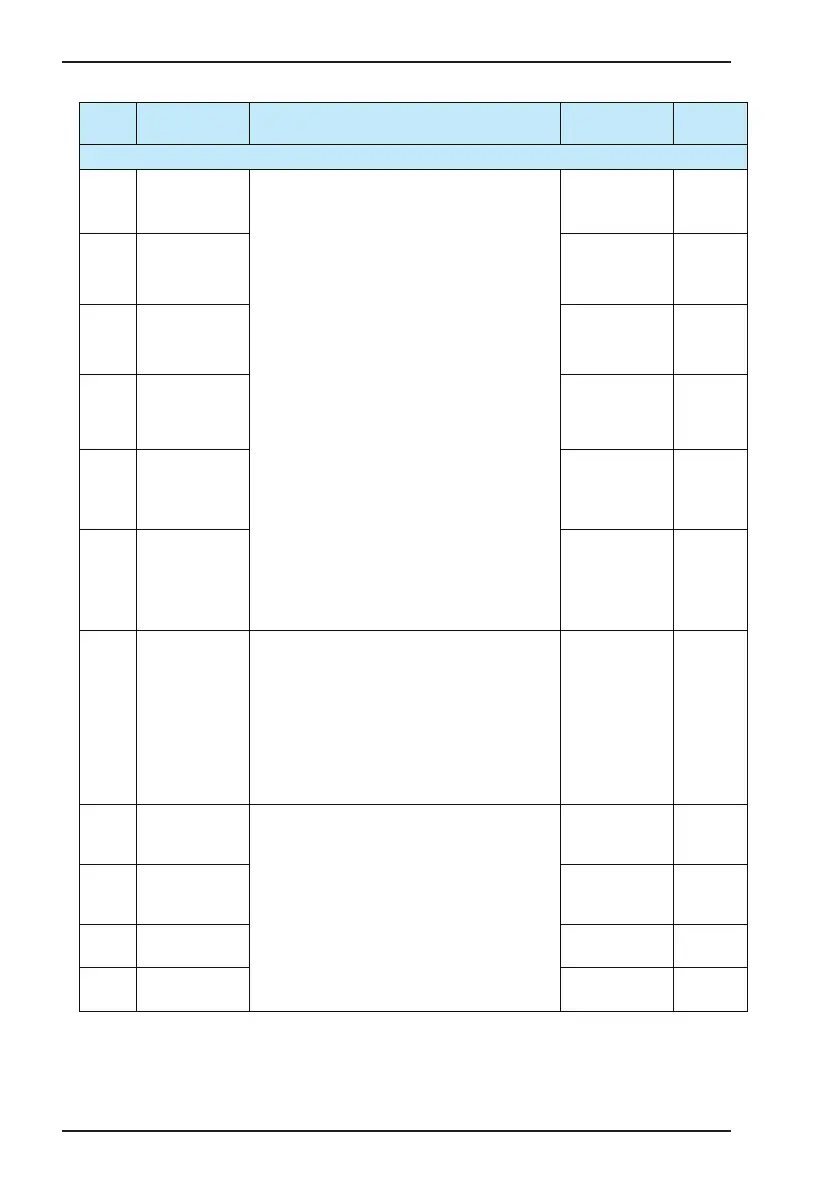

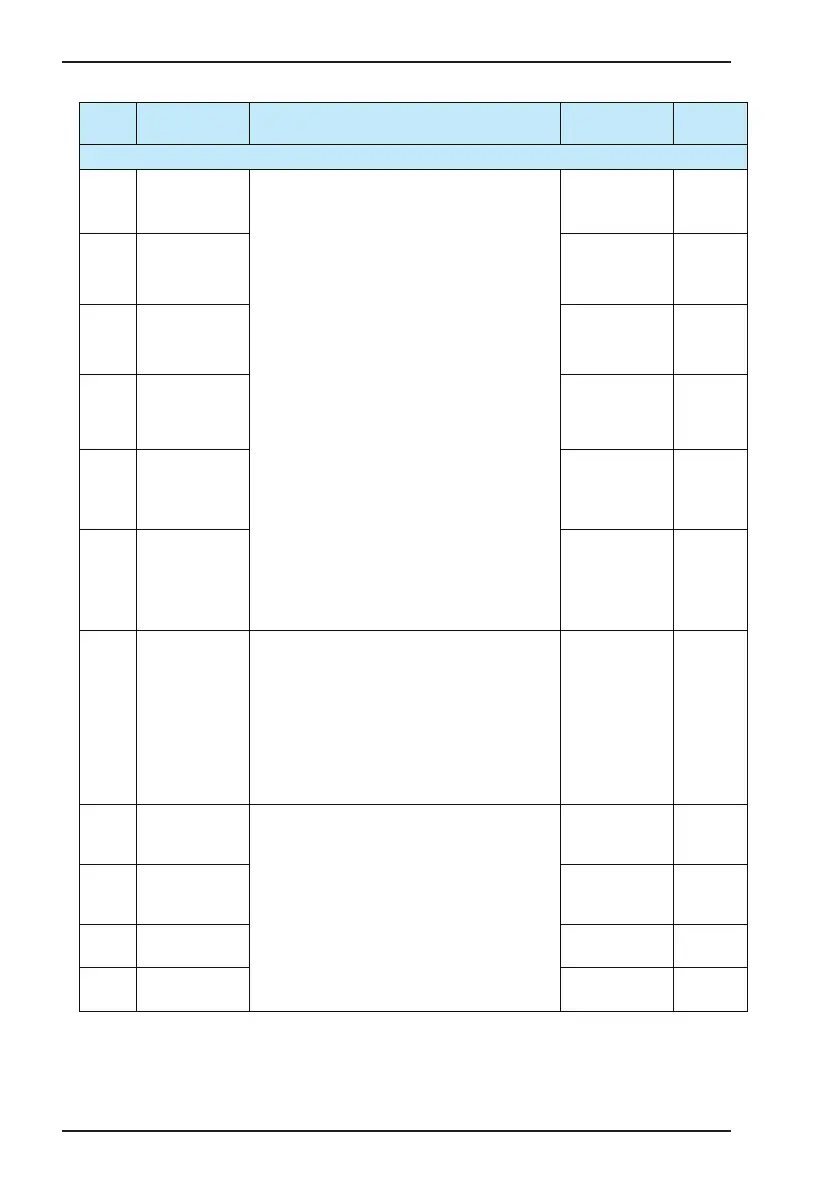

Chapter 5 Function Code Table

- 86 -

Function

Code

Parameter Name Description Setting Range Default

Group F1: Vector Control Parameters

F1.00

Speed loop

proportional gain 1

The speed loop PI parameters are selected according

to the running frequency of the AC drive. If the

frequency reference is smaller than the switchover

frequency 1 (F1.02), the speed loop parameters

are F1.00 and F1.01. If the frequency reference is

larger than the switchover frequency 2 (F1.05), the

speed loop PI parameters are F1.03 and F1.04. If the

frequency reference is between F1.02 and F1.05, the

two groups of speed loop PI parameters are switched

over linearly.

The speed dynamic response in vector control can be

adjusted by setting the proportional gain and integral

time of the speed regulator.

To achieve a faster system response, increase the

proportional gain and reduce the integral time. Be

aware that this may lead to system oscillation.

If the default setting cannot satisfy requirements, make

ne adjustment. Increase the proportional gain rst

to ensure no system oscillation, and then reduce the

integral time to ensure quick system response and

small overshoot.

Note: Improper setting of PI parameters may result

in too large overshoot and even overvoltage during

overshoot drop.

1 to 100 60

F1.01

Speed loop integral

time 1

0.01s to 10.00s 0.50s

F1.02

Switchover

frequency 1

0.00 Hz to F1.05 5.00 Hz

F1.03

Speed loop

proportional gain 2

1 to 100 20

F1.04

Speed loop integral

time 2

0.01s to 10.00s 1.00s

F1.05

Switchover

frequency 2

F1.02 to b1.02 10.00 Hz

F1.06

Time constant of

speed loop lter

In vector control, the output of the speed loop regulator

is torque current reference. This parameter is used to

lter the torque reference. It rarely need be modied.

Increase the lter time in the case of big speed

uctuation, and decrease it in the case of motor

oscillation.

If the speed loop lter time constant is small, the output

torque of the AC drive may uctuate greatly but the

response is quick.

0.000s to 1.000s 0.080s

F1.08

Excitation

adjustment

proportion gain

These are current loop PI parameters for vector control.

They are obtained automatically through the motor

auto-tuning 2 and rarely need be modied.

Note: The integral regulator of the current loop does

not take integral but integral gain as the dimension.

Too large setting of the current loop PI gain may lead

to oscillation of the entire control loop. Therefore, when

current oscillation or torque uctuation is very large,

decrease the proportional gain or integral gain here.

0 to 20000 2000

F1.09

Excitation

adjustment integral

gain

0 to 20000 1300

F1.10

Torque adjustment

proportion gain

0 to 20000 2000

F1.11

Torque adjustment

integral gain

0 to 20000 1300

Loading...

Loading...