19

6.1.2 Thermostatic radiator valves

6.1.1 Expansion vessel

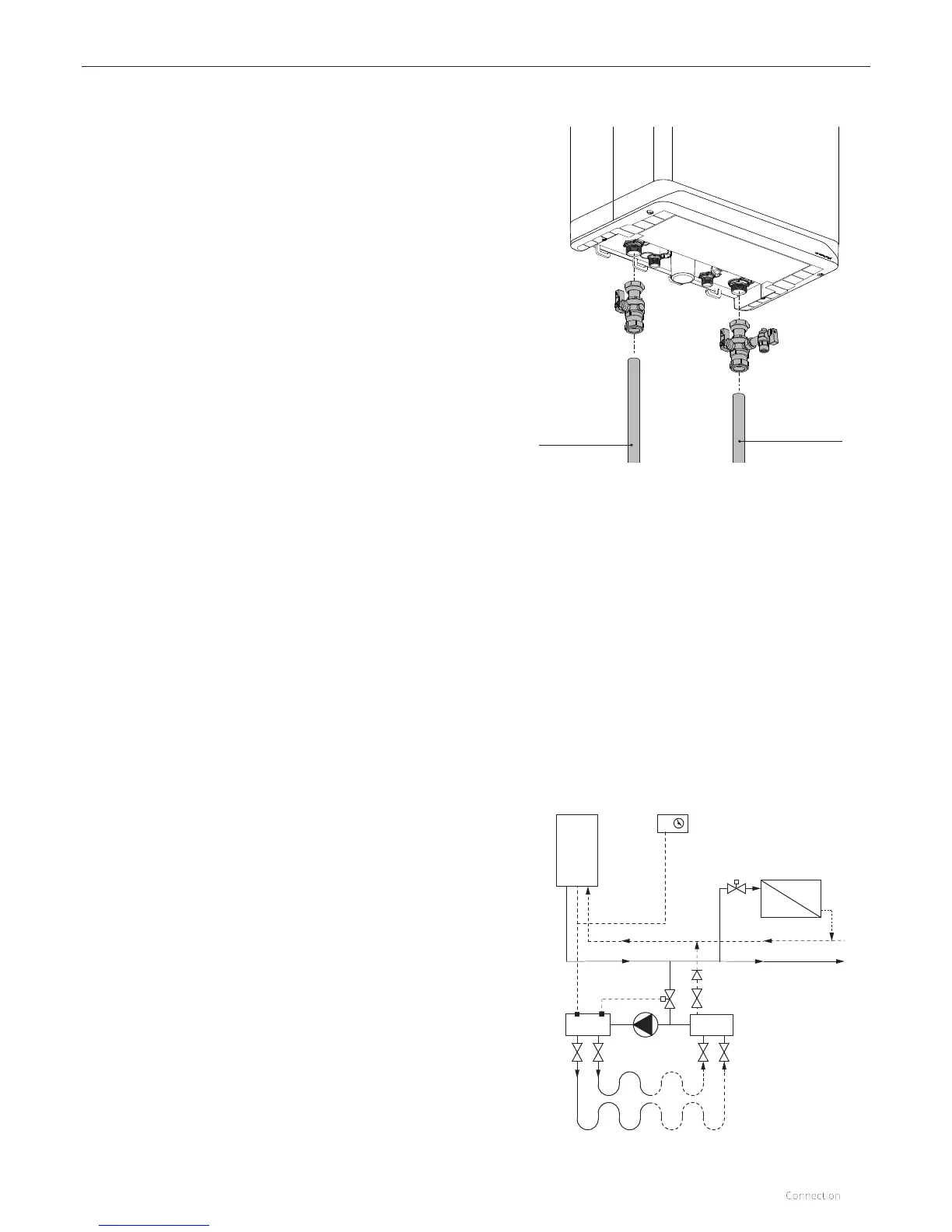

► Flush the central heating system thoroughly.

► Fit the flow and return pipes to the isolation valves.

► All pipes must be fitted unstressed in order to prevent pipes

from ticking.

► Existing connections must not be twisted, in order to avoid

leakages.

The CH system should be equipped with:

► A drain tap in the return pipe immediately below the

appliance.

► A drain tap at the lowest point(s) of the installation.

► A non return valve, if pipes run upwards at a short

distance from the appliance. This avoids the occurrence of

thermosyphon eect during DHW operation mode.

If all radiators have thermostatic radiator valves or valves that

can be closed to separate the flow completely from the return,

a minimum amount of water circulation must be ensured by

the installation of bypass piping, for example (also see §8.5).

The appliance is fitted with a expansion vessel adequate for a

system with a water volume not exceeding 100 litres, typically 8

radiators. For larger volume systems, an additional expansion

vessel must be fitted. Contact Intergas for advice in these cases.

6 CONNECTION

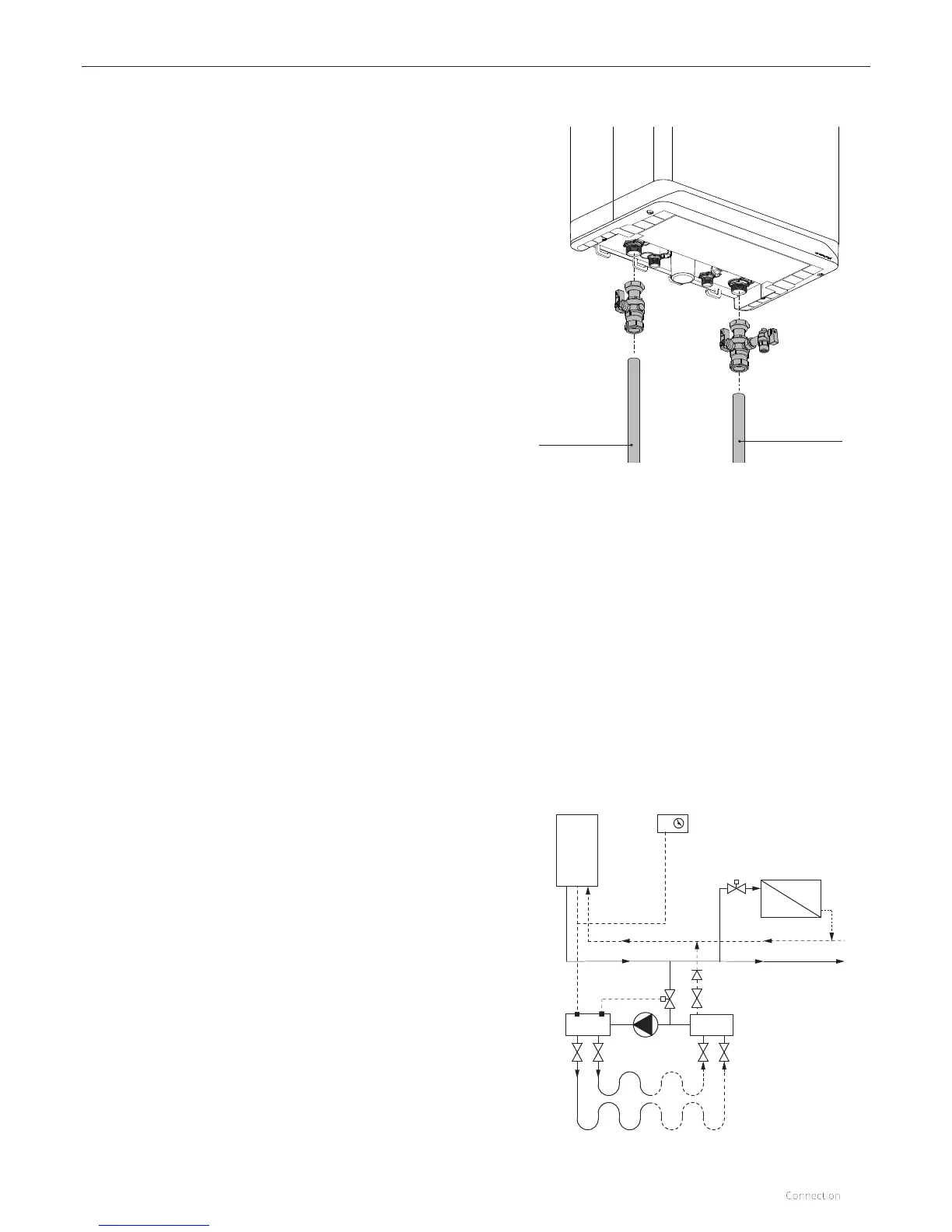

6.1.3 Floor heating

Floor heating with pump

For eective operation of the DHW supply any undesired

circulation through the appliance as a result of a second pump

in the CH circuit must be avoided.

Connect the floor heating system in a hydraulically neutral

manner to the appliance, or equip the CH circuit with an

electric shut-o valve or check valve to prevent flow

through the appliance when there is no CH request for heat.

Make sure there is a minimum of water circulation; see §8.5.

Underfloor heating connection diagram

A. Boiler

B. Central heating pump

C. Thermostatic control valve

D. Spring-operated non-return valve

E. Electric shut-o valve 230V~

F. Radiators

G. Room/clock thermostat

H. Maximum thermostat

A

G

H

F

C

B

C

E

D

6.1 Connecting the central heating system

Return pipe

Flow piping

Loading...

Loading...