68

10 MAINTENANCE

► Clean the slats of the heat exchanger from top to bottom with a

brush or vacuum cleaner.

► Clean the underside of the heat exchanger.

► Clean the siphon with water.

► Only clean the underside of the front panel.

CAREFUL

► The integrated insulation panel and burner

seal contain ceramic fibres.

CAREFUL

► Aer work activities, check all flue supply

piping parts for tightness.

► Some components can be hot when the boiler

has just been in operation.

10.1 Disassembly

10.2 Cleaning

The boiler and the system must be inspected annually by an qualified competent gas safe registered engineer and

cleanded if necessary. The annual maintenance interval is based on an expected operation time of approx. 1,500 heating

hours/year (average domestic use), via Comfort Touch dashboard and installerd app. If not monitored by Comfort Touch

then the boiler must be serviced annually.

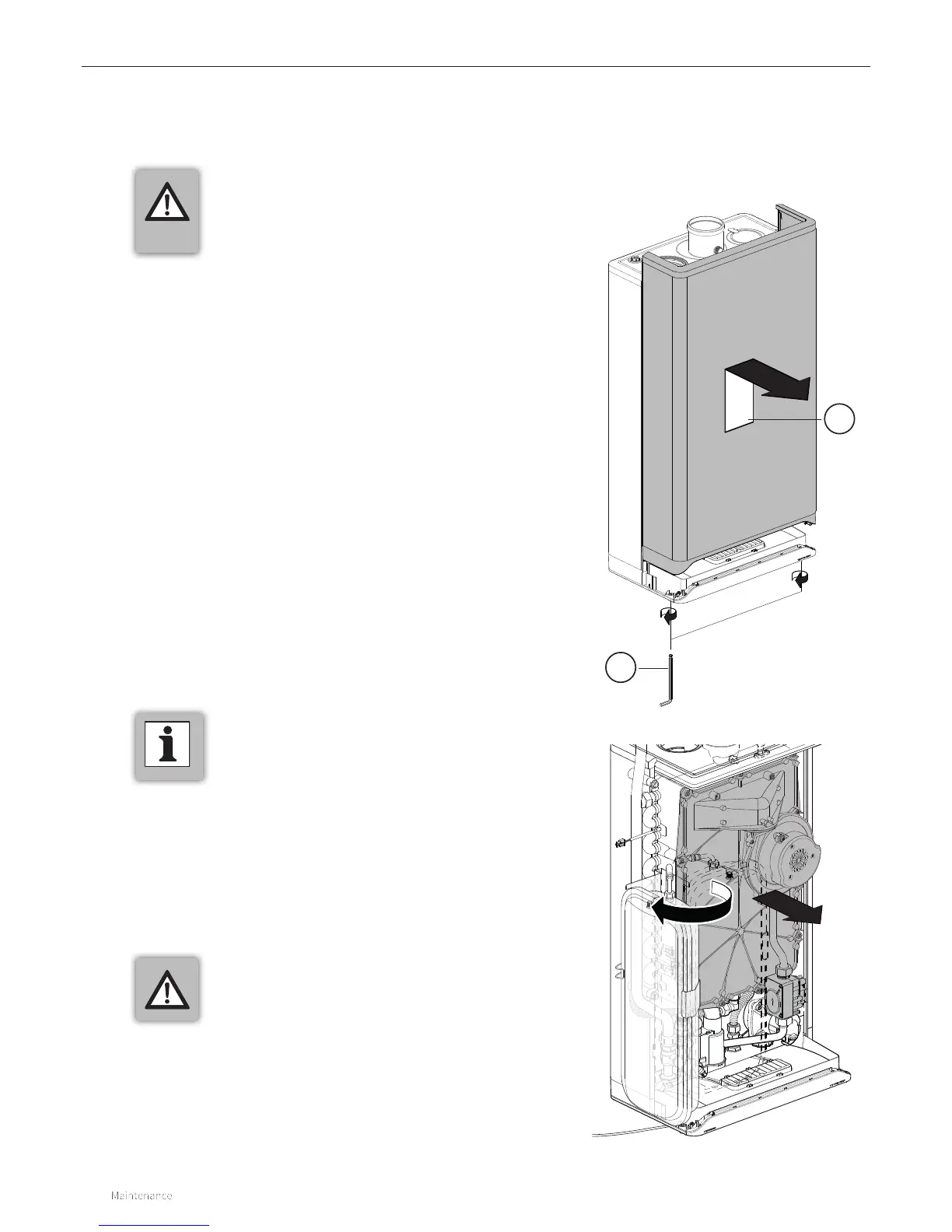

1

2

► Switch o the appliance and isolate the power supply at the fuse

spur, make safe the appliance before continuing (Ref TB118).

► Close the gas valve.

► Remove the front panel of the boiler by unscrewing the two

screws (1) and then removing the panel up and forward (2).

► Wait until the boiler has cooled down. This can be done by

opening a domestic hot water tap.

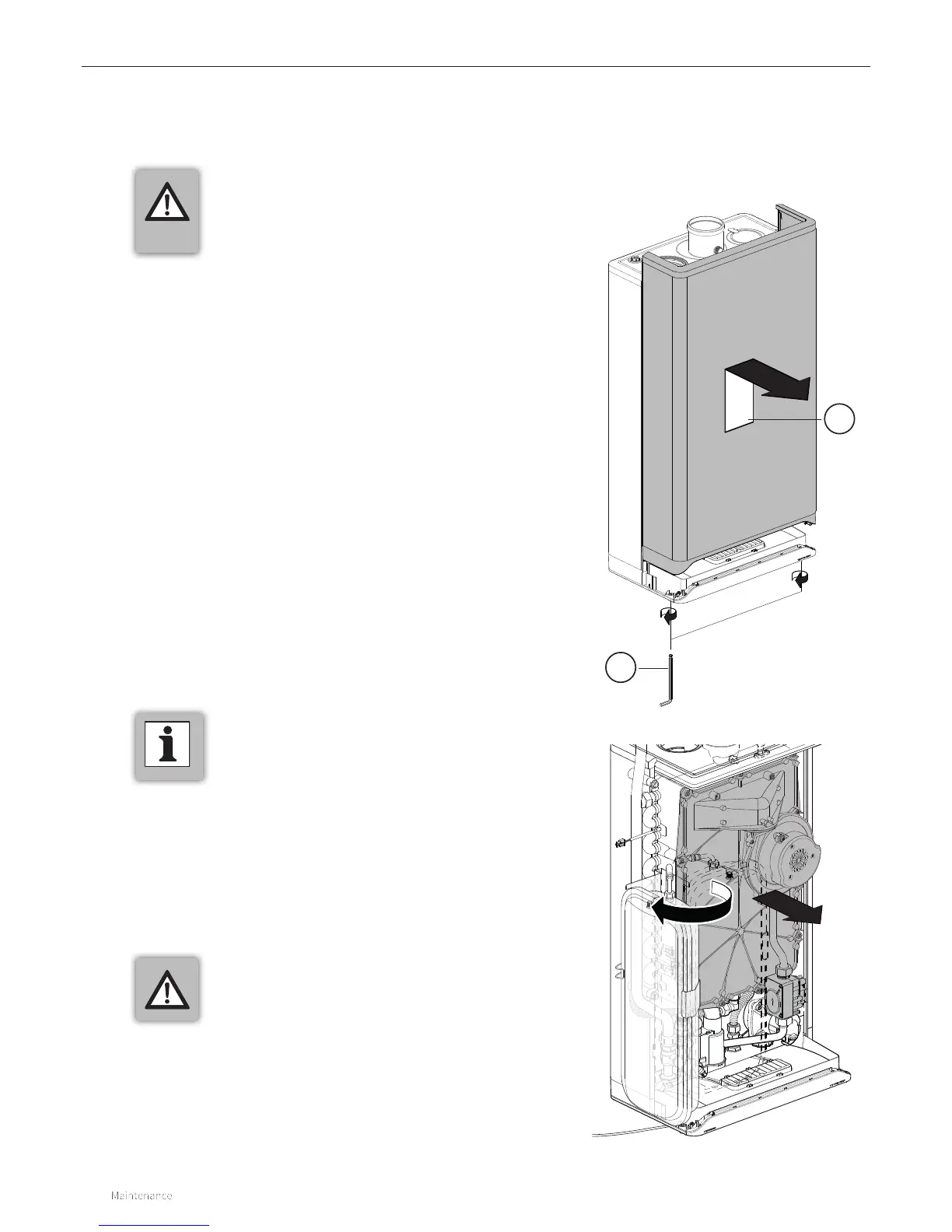

► Turn the expansion vessel aside.

► Disconnect the connector of the fan.

► Disconnect the connection under the gas valve.

► Unscrew the shoulder bolts (socket) of the front cover and

remove the cover forward with the gas valve and fan (pay

attention that the burner, insulation panel, gas valve, gas piping

and the fan do not become damaged). Lay the removed front

cover with the foot supports horizontal on a smooth surface.

► The burner and the integrated insulation panel do not require

maintenance (do not need to be cleaned). Therefore, never use a

brush or compressed air to clean these components so that the

development of dust is avoided.

► Remove the siphon cup by turning it counter-clockwise and then

removing it downwards.

COMMENT

► The expansion vessel must be inspected and

tested at each annual service and if required

re-pressure to 0.75 bar.

Loading...

Loading...