INVT SV-DA200 AC Servo Drive PROFINET Technical Guide V2.63

39

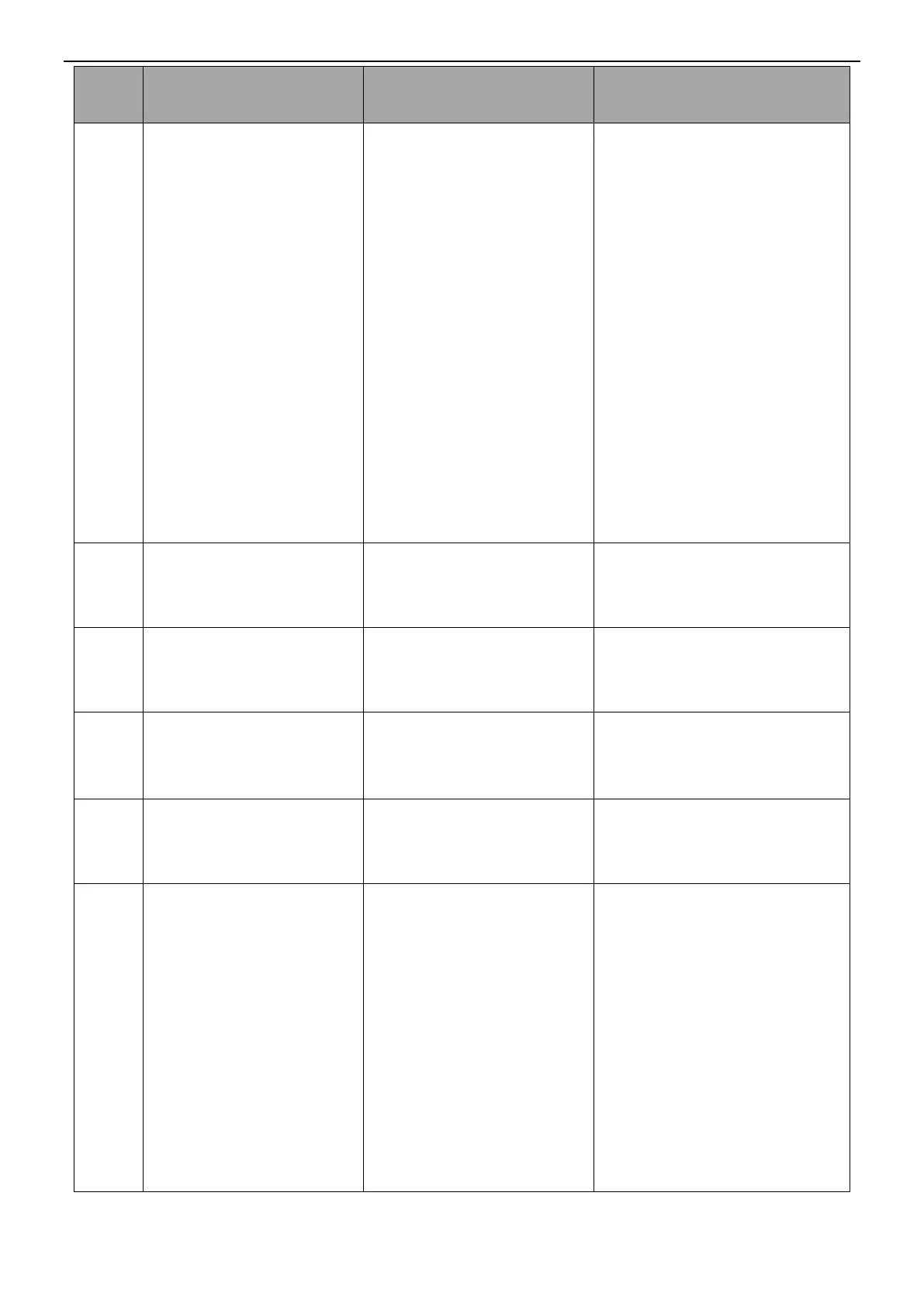

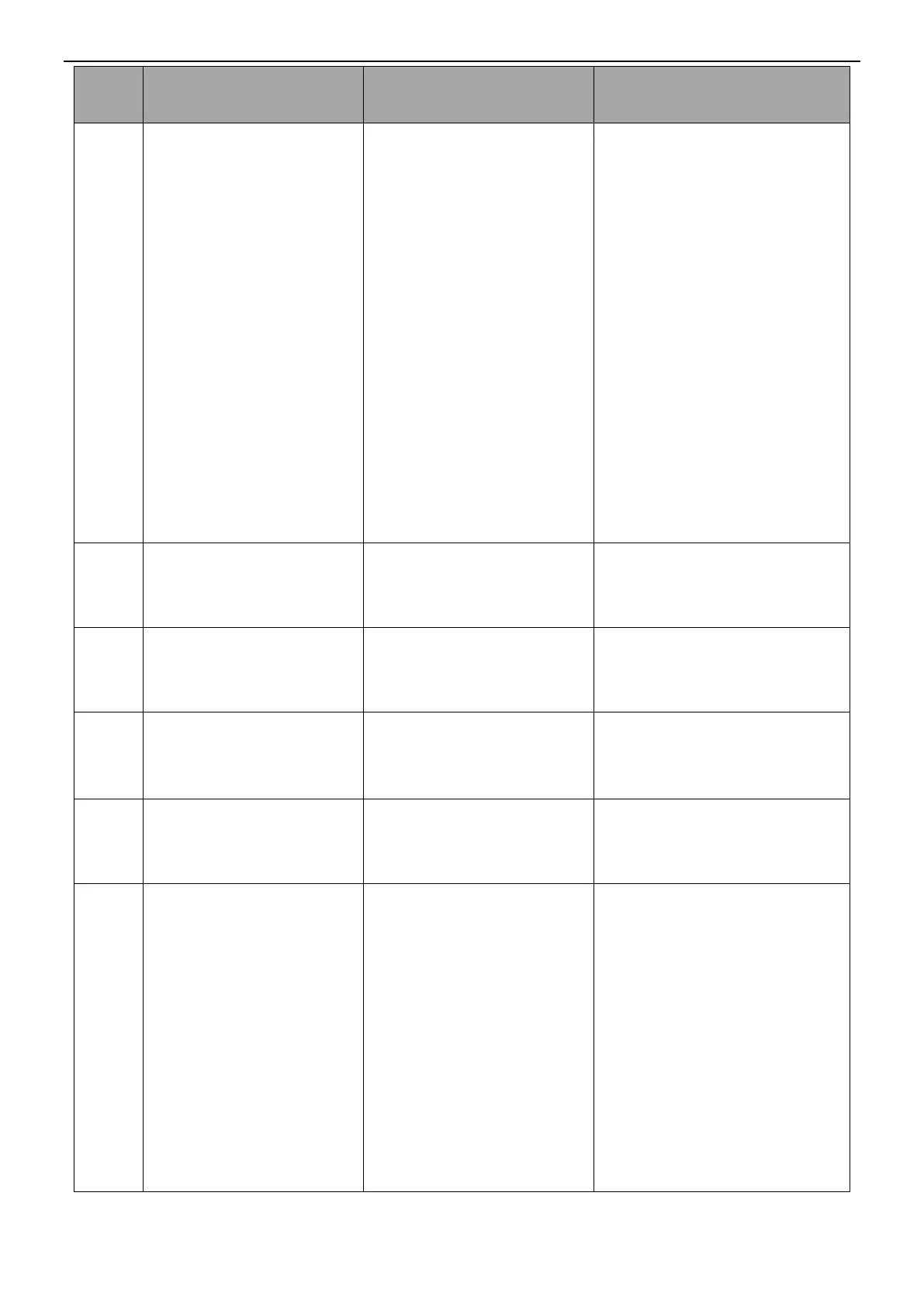

Speed fault–Overspeed

fault

The motor speed absolute

value exceeds the setting of

P4.32.

1. The motor stalls or motor

phases U, V, and W are in

reverse sequence.

2. The electronic gear ratio or

motor speed loop control

parameters are not set

properly.

3. The setting of P4.32 is less

than that of P4.31 [Max.

speed limit].

4. The encoder feedback

signal is interfered.

1. Ensure the electronic gear

ratio is set properly.

2. Ensure the motor speed loop

control parameters are set

properly.

3. Ensure the motor cable

phases are in correct sequence.

4. Ensure the motor and encoder

are connected properly.

5. Replace the motor with a new

one with a higher speed.

Speed fault–FWD

overspeed fault

The speed feedback exceeds

the setting of P4.40 by more

than 20ms.

1. Ensure the encoder is normal.

2. Set P4.40 properly.

Speed fault–REV

overspeed fault

The speed feedback exceeds

the setting of P4.41 by more

than 20ms.

1. Ensure the encoder is normal.

2. Set P4.41 properly.

Speed fault–Incorrect

overspeed parameter

setting

The setting of P4.40 is less

than 0 or that of P4.41 is

greater than 0.

1. Ensure the encoder is

connected properly.

2. Set P4.40 or P4.41 properly.

The motor phase sequence is

incorrect or the initial angle is

incorrect.

1. Ensure the motor phases are

in correct sequence.

2. Set P4.96.

Speed

out-of-tolerance-range fault

In non-torque mode, the

deviation between the motor

speed and speed command

exceeds the setting of P4.39.

1. The motor phases U, V,

and W are in reverse

sequence or motor cables are

not connected.

2. The motor load is too

heavy, which causes motor

stalling.

1. Ensure the motor phases are

in correct sequence and motor

cables are connected properly.

2. Check whether the conveyor

belt or chain is too tight or the

workbench reaches the

boundary or encounters

obstacles. If yes, resolve the

problem.

3. Ensure the speed loop control

parameters are set properly, the

Loading...

Loading...