Page 40

2. Brushwithamildlyabrasivegreenberhouseholdcleaningpad.Contactsshouldbecleanandbright.

3. Thoroughly rinse the ow/temp/salinitysensor with clean tap water. Replace and resume normal

operation.

4. Turn power off and back on in order to recalibrate and reset Flow/Temp/Salinity Sensor. Reset

anytime Flow/Temp/Salinity Sensor is unplugged.

6.5 Winterizing

Verylittlechlorineisneededincoldwater.Below51°F(11°C),chlorineproductionisnotpermitted;

operating the chlorinator in cold water might result in over-chlorinated pool water. If more chlorine is

needed, activating the “Boost” mode will override this cold water feature allowing chlorine production

for 24 hours of operation. See Section 5.1, User Interface Controls.

If preventative measures are not taken, freezing water may cause severe damage to the cell and ow/

temp/salinity sensor. Prevent freeze damage to the cell and ow/temp/salinitysensor by running pump

continuouslyorwinterizepoolbydrainingwaterfrompump,lter,andallintakeandreturnlines.Remove

the cell, clean and store it. Disconnect the ow/temp/salinitysensor from the power center, then remove it

from the 3-port cell. Wrap ow/temp/salinitysensor in a plastic bag or protective covering and coil ow/

temp/salinity sensor and DC power cord cables around the power center for storage.

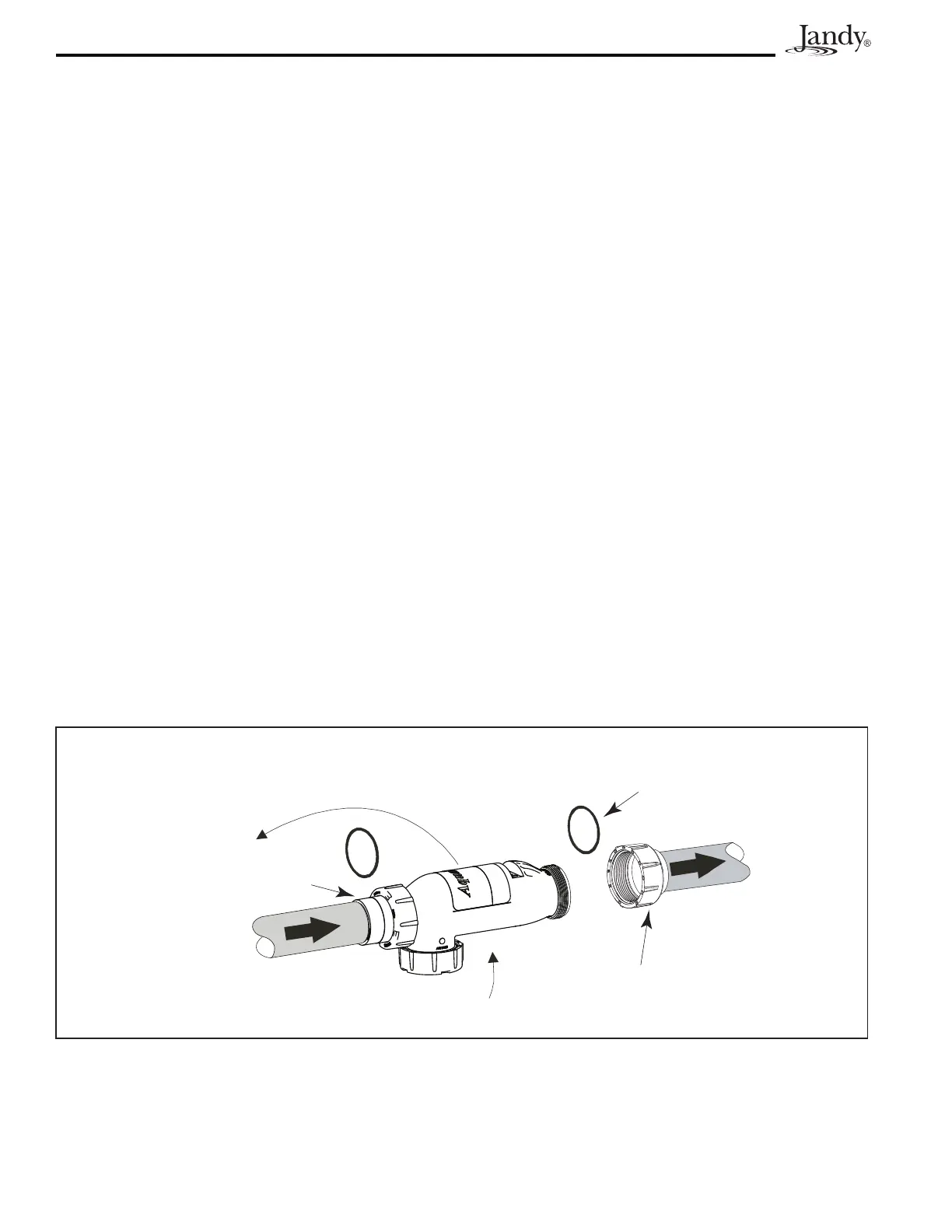

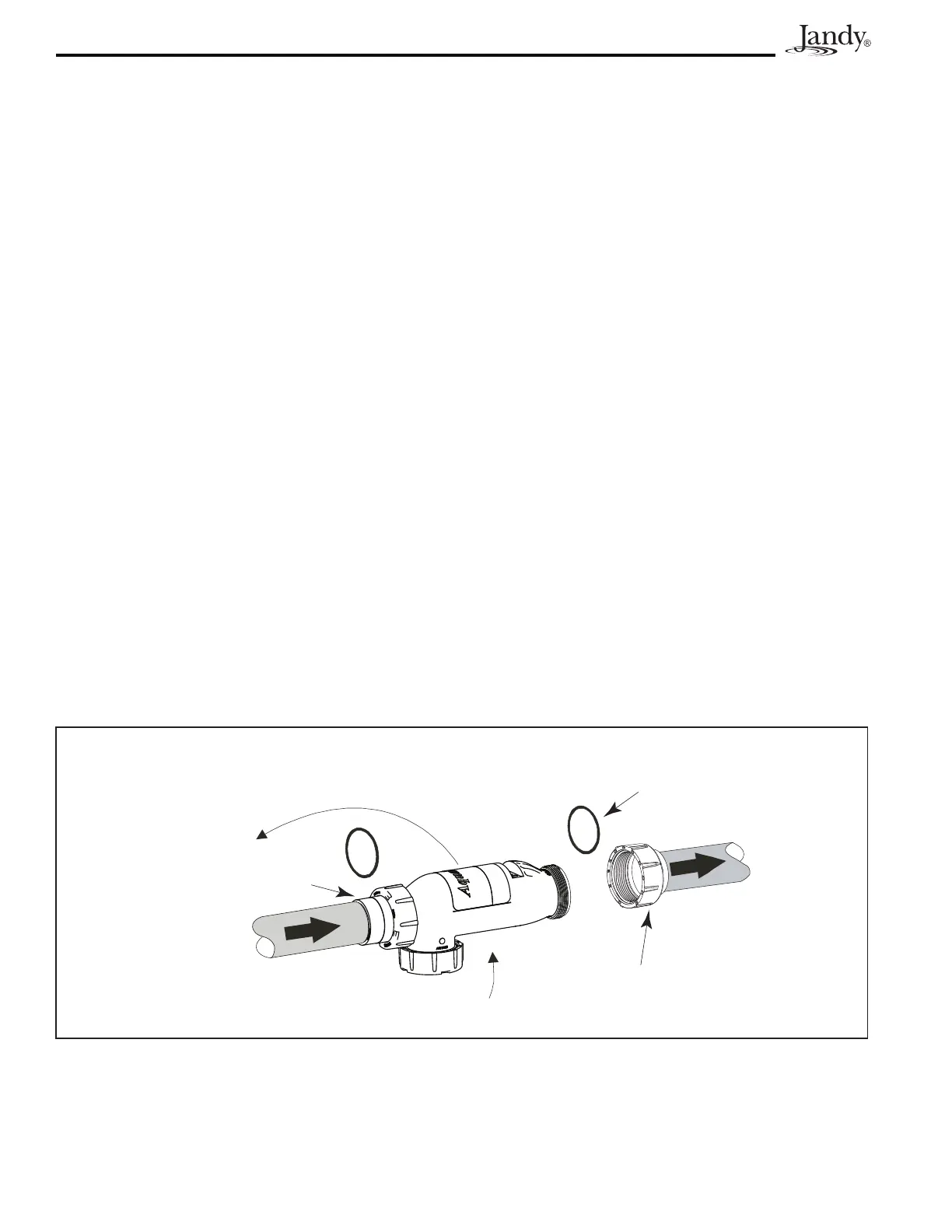

An optional Spool Piece (sold separately) is available to replace the cell during winterizing or cell

maintenance.Thiswillenablepoolpumptocirculatewaterwiththecellouttheofline.SeeFigure19.

When a FREEZE CONTROLLER is used on pump equipment and the chlorinator is run through the winter,

turn the CHLORINE PRODUCTION down to 10 - 20%. Otherwise, chlorine production will exceed the

recommended level of 1 - 3 ppm.

NOTE A chlorine level above 3 ppm may cause corrosion of pool metals and possibly cause damage to associated

pool equipment.

O-Ring

Seal

PVC Union

and 2” Nut

Insert Spool Piece

Remove Cell

PVC Union

Figure 19. Spool Piece Location

Loading...

Loading...