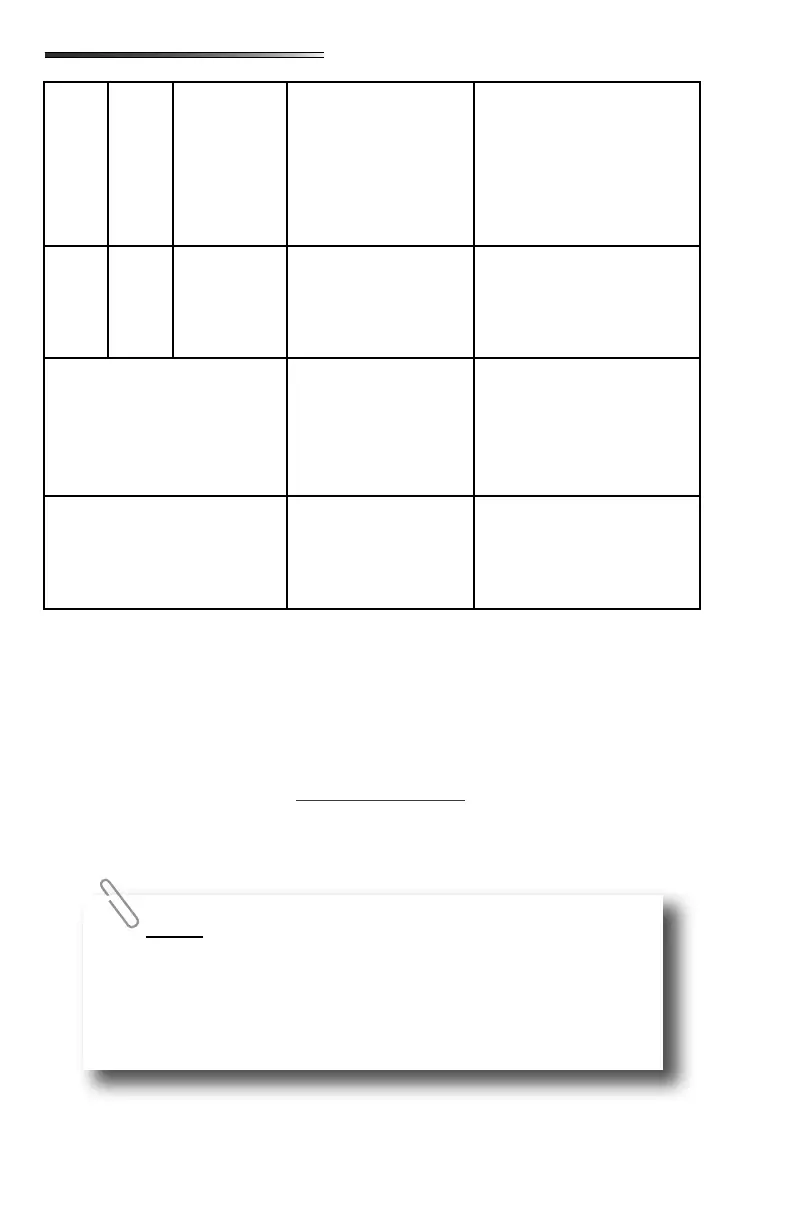

84

4 Major

Excessive

Battery Volt-

age

-Bad or loose connec-

tion

-Defective harness

-Open or shorted motor

-Check all connections at

control box and motor.

-Check the harness for bro-

ken wires.

-Put 12.0 VDC direct to

the motor. If it does not run

replace the motor.

6 Minor

Supply voltage to con-

trol box is 17 0 V DC

or greater

Check 2-pin power con-

nector at control box. If

the voltage is 17. VDC or

higher, contact O.E.M for

power and ground supplies

Park brake LED ashing

-Parking brake not set

(if applicable)

-Ground signal lost at

park brake control

-Set parking brake (if ap-

plicable)

-Check for continuity to

ground on wire plugged

into park brake connector at

control box.

Low voltage LED ashing

Incoming violated to

control box is below

12.0 VDC

Check 2-pin power connec-

tor at control box. If voltage

is below 12.0 VDC contact

O.E.M for power and ground

supplies.

The Power Gear® slideout system requires very little maintenance. Read and follow these

procedures:

When the room is extended, visually inspect the slide rail assemblies. Check for

excess buildup of dirt or foreign material; remove any debris that may be present.

If the system squeaks or makes any noises, blow out any debris from the gear rack

arms and apply a dry lubricant to prevent and/or stop squeaking.

Refer to the Power Gear® website www.powergearus.com for additional information.

In the event of component failure or loss of system power, your slideout can be manually

overridden and retracted for travel.

During the override procedure, the unit will exit this mode if the

room has not been moved for two (2) minutes or if a fault is detected during

room movement. The Fault Code (RED) and Room or Lock Movement

(GREEN) LEDs will ash rapidly for 10 seconds to indicate the override

procedure failed. After 10 seconds of ashing, the control will automatically

default to FAULT CODE 1. Programming must be restarted.

Loading...

Loading...