362247-BIM-B-0109

Johnson Controls Unitary Products 47

GAS HEATING SEQUENCE OF OPERATION

When there is a W1 call for heat, the heat relay (RW1)

is energized by the unit control board (UCB). The

RW1-1 contacts immediately close energizing the igni-

tion control board (ICB). The ICB checks the state of

the flame sense circuit, the roll out switch, the centrifu-

gal switch and the primary / auxiliary temperature limit

switch circuit. If they are in the expected state, then the

ICB energizes the draft motor and verifies that the cen-

trifugal switch located on the end of the draft motor

closes. After the centrifugal switch closes, a 15 second

heat exchanger purging period is completed. After this

purging period, the ICB will simultaneously energize

the pilot gas valve and the ignition coil. Once the flame

sensor senses a pilot flame is present, the ignition coil

is de-energized. The ICB checks for pilot flame stability

and once the ICB is satisfied that the pilot flame is sta-

ble, the main gas valve is energized by the ICB. The

UCB will energize the indoor blower after a 45 second

delay from the call for heat. The ICB and UCB both

monitor the furnace safety devices during the furnace

operation. When the call for heat is satisfied, the ICB

closes the pilot and main gas valves and performs a 30

second purging of the heat exchanger by continuing

the operation of the draft motor. The UCB continues

the operation of the indoor blower for a configurable

amount of time after the call for heat is satisfied.

TWO STAGE FURNACE ONLY

If a W1 only call for heat from a two stage thermostat is

present, then a two stage furnace will start on high fire

for 1 minute and then reduce to low fire until the call for

heat is satisfied or a W2 call for heat is received. If a

W2 call for heat is received while in low fire operation,

then the ICB will immediately move to high fire opera-

tion. If a W1 and W2 call for heat is present, then the

furnace will remain on high fire operation until the W2

call for heat is satisfied.

Automatic staging of a two stage furnace using a single

stage thermostat is possible. To achieve automatic

staging of a two stage furnace using a single stage

thermostat, cut the 440/GY wire that runs from pin 2 of

the S3 connector on the (UCB) unit control board to

P2-4 on the ignition control board. Cut the wire 1/2”

from the S3 mate-n-lock connector. Wire nut or tape off

the 1/2” wire. Attach the other end of the 440/GY wire

to the R terminal on the UCB, or to the TB1 power strip.

The unit will operate the same as a W1 only call for

heat for 10 minutes. If the call for heat is not satisfied in

the 10 minutes, then the ICB will move to high fire

operation until the W1 call for heat has been satisfied.

GAS HEAT OPERATION ERRORS

During furnace operation, the ICB monitors the flame

sense circuit, the centrifugal switch, the primary limit

switch and the roll out switch. If a signal from any of the

inputs moves to a fault state, then the ICB immediately

closes the pilot and main gas valves. The ICB will

determine the device that is signaling a fault and flash

a code for that device. A primary limit trip, centrifugal

switch trip or flame sense fault triggers a temporary

lock out. An auxiliary limit or a roll out switch trip

requires intervention to reset the ICB. The UCB also

monitors the primary limit and gas valve.

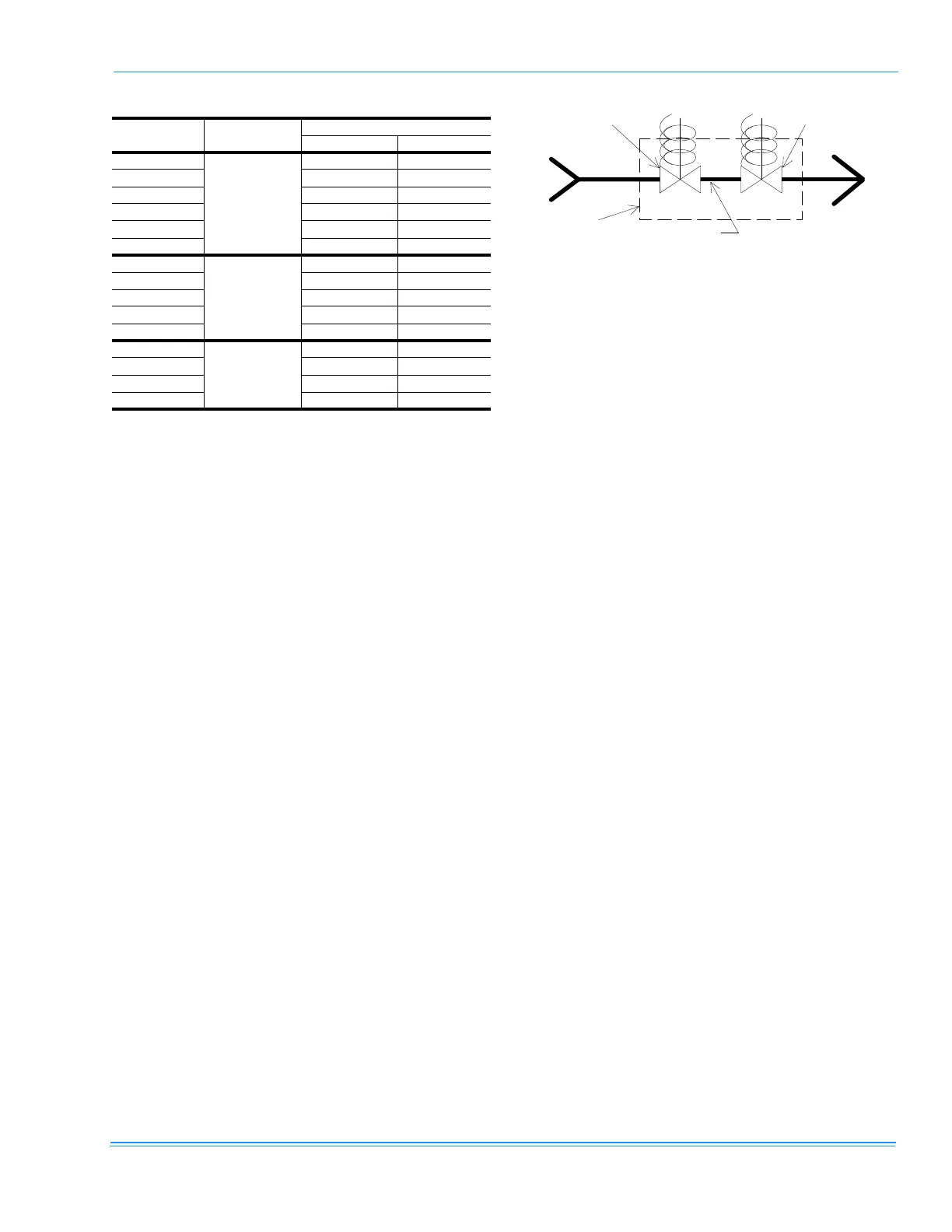

TABLE 32:ELECTRIC HEAT ANTICIPATOR SETPOINTS

HEATER

KW

VOLTAGE

SETTING, AMPS

TH1 TH2

5

230-3-60

0.35 -

70.35-

10 0.35 -

15 0.35 0.19

20 0.35 0.38

30 0.35 0.38

7

460-3-60

0.35 -

10 0.35 -

15 0.35 -

20 0.37 0.29

30 0.37 0.29

10

575-3-60

0.35 -

15 0.35 -

20 0.37 0.29

30 0.37 0.29

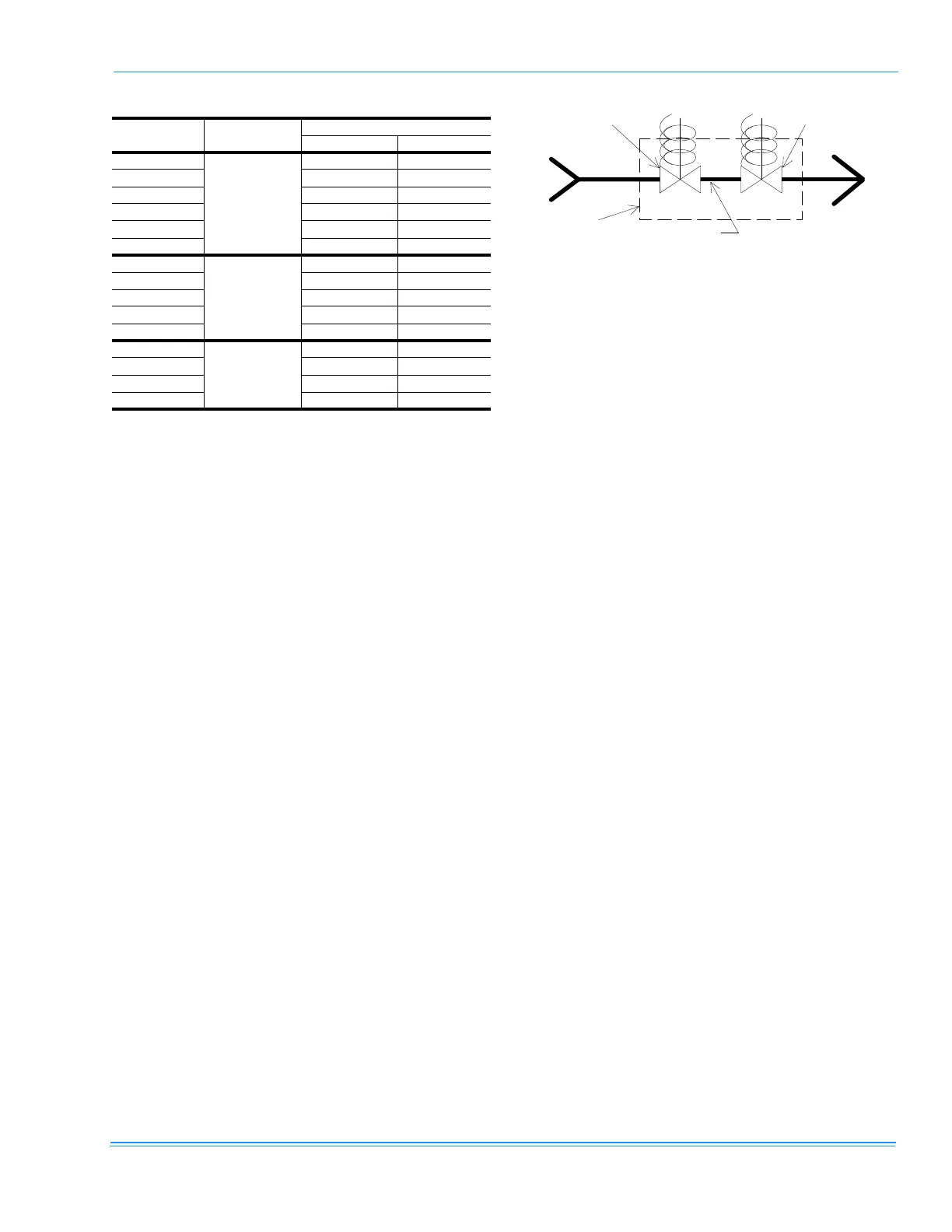

FIGURE 18 - GAS VALVE PIPING

GAS

VALVE

GAS MAIN

MAIN VALVE

TO MAIN

BURNER

REDUNDANT

VALVE

TO PILOT BURNER

Loading...

Loading...