362247-BIM-B-0109

Johnson Controls Unitary Products 51

MANIFOLD GAS PRESSURE ADJUSTMENT

Adjustments to the high-fire and low-fire (2 stage) gas

flow may be made by turning the pressure regulator

adjusting screws on the automatic gas valve.

Adjust as follows:

1. Remove the adjustment screw cap(s) on the regu-

lator.

2. To decrease the gas pressure, turn the adjusting

screw counterclockwise.

3. To increase the gas pressure, turn the adjusting

screw clockwise.

4. Replace adjustment screw caps.

NOTE: The factory set high-fire manifold pressure for

these furnaces is 3.50 IWG. The actual mani-

fold pressure depends on the local fuel heating

value.

PILOT CHECKOUT

The pilot flame should envelope the end of the flame

sensor. To adjust pilot flame, (1) remove pilot adjust-

ment cover screw, (2) increase or decrease the clear-

ance for air to the desired level, (3) be sure to replace

cover screw after adjustment to prevent possible gas

leakage.

Put the system into operation and observe through

complete cycle to be sure all controls function properly.

BURNER INSTRUCTIONS

To check or change burners, pilot or orifices, CLOSE

MAIN MANUAL SHUT-OFF VALVE AND SHUT OFF

ALL ELECTRIC POWER TO THE UNIT.

1. Remove the screws holding either end of the mani-

fold to the burner supports.

2. Open the union fitting in the gas supply line just

upstream of the unit gas valve and downstream

from the main manual shut-off valve.

3. Remove the gas piping closure panel.

4. Disconnect wiring to the gas valves and spark ignit-

ors. Remove the manifold-burner gas valve

assembly by lifting up and pulling back.

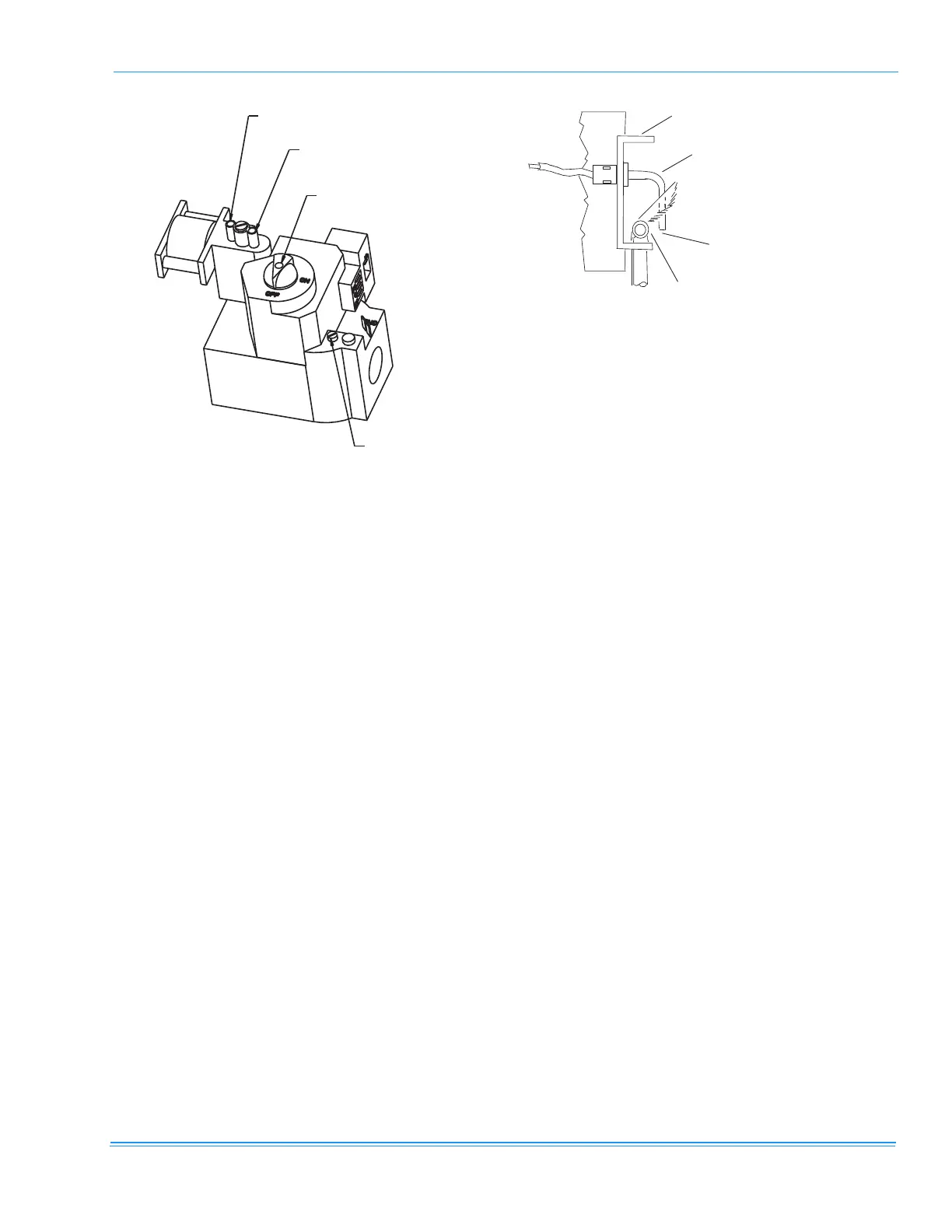

FIGURE 20 - TYPICAL 2 STAGE GAS VALVES

REGULATOR ADJ. “HI”

(UNDER SCREW)

REGULATOR ADJ. “LO”

(UNDER SCREW)

“ON” - “OFF” CONTROL

PILOT ADJ.

(UNDER SCREW)

HONEYWELL

VR820RQ

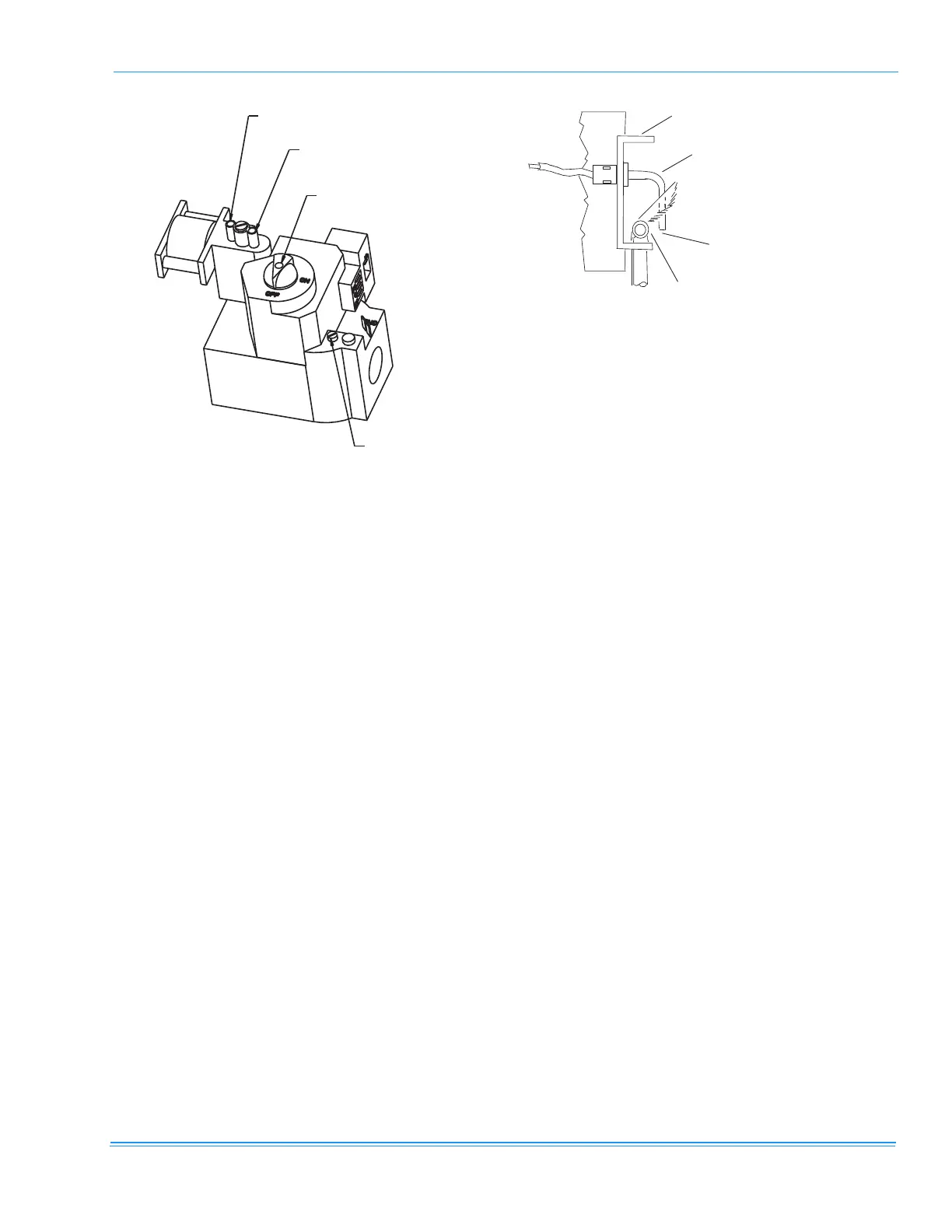

FIGURE 21 - PROPER FLAME ADJUSTMENT

1 / 8 " G A P B E T W E E N C A R R Y - O V E R

T U B E A N D F L A M E S E N S O R B U L B

C A R R Y - O V E R T U B E

F L A M E S E N S O R B U L B

B U R N E R A S S E M B L Y B R A C K E T

Loading...

Loading...