362247-BIM-B-0109

Johnson Controls Unitary Products 9

and 19 for the clearances required for combustible con-

struction, servicing, and proper unit operation.

DUCTWORK

Ductwork should be designed and sized according to

the methods in Manual Q of the Air Conditioning Con-

tractors of America (ACCA).

A closed return duct system shall be used. This shall

not preclude use of economizers or outdoor fresh air

intake. The supply and return air duct connections at

the unit should be made with flexible joints to minimize

noise.

The supply and return air duct systems should be

designed for the CFM and static requirements of the

job. They should NOT be sized to match the dimen-

sions of the duct connections on the unit.

Refer to Figures 10 through 14 for information concern-

ing side and bottom supply and return air duct openings.

NOTE: It is recommended that, in Canada, the outlet

duct be provided with a removable access

panel. It is recommended that this opening be

accessible when the unit is installed in service,

and of a size such that smoke or reflected light

may be observed inside the casing to indicate

the presence of leaks in the heat exchanger.

The cover should be attached in a manner

adequate to prevent leakage.

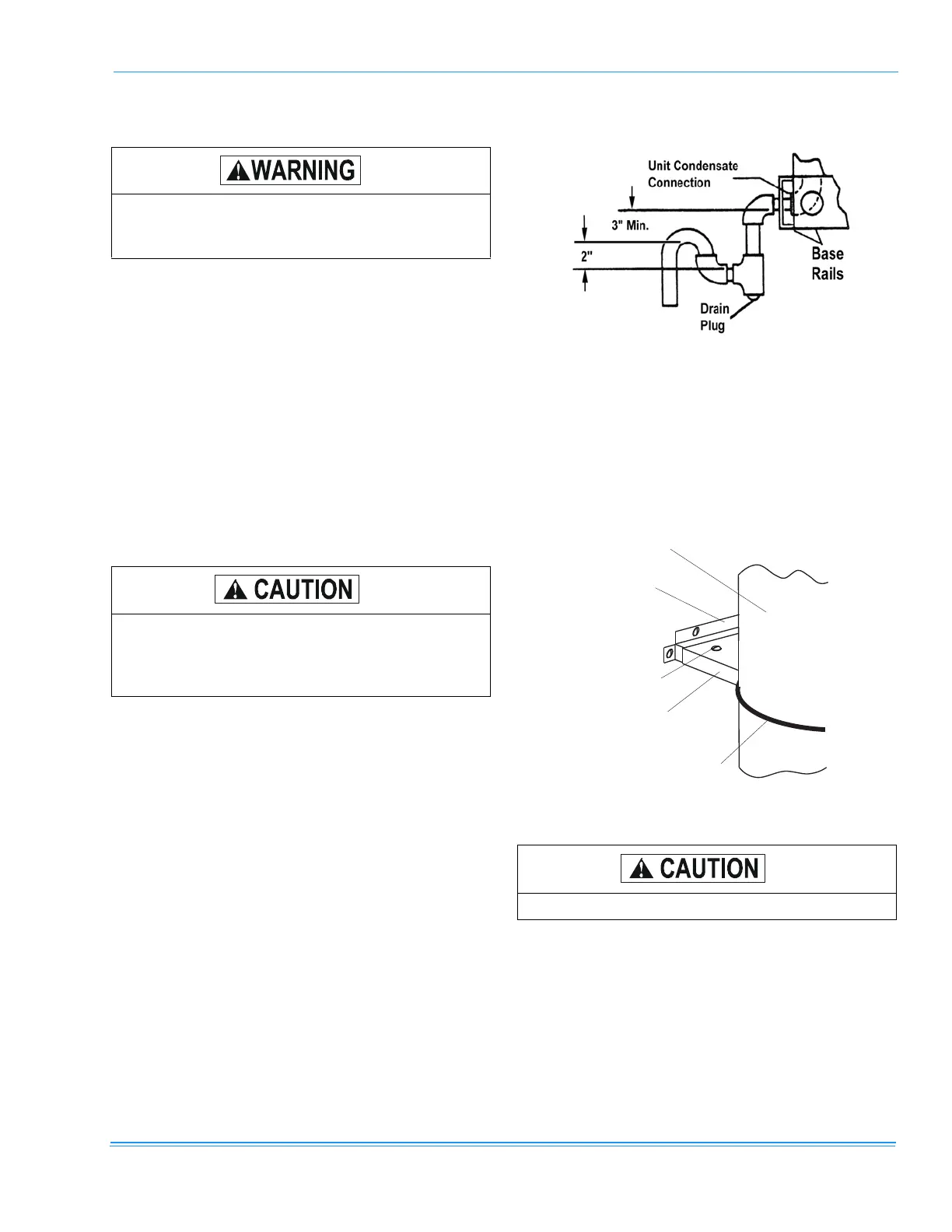

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate

drain line from the 3/4” NPT female connection on the

unit to an open drain.

NOTE: The condensate drain operates in a negative

pressure in the cabinet. The condensate drain

line MUST be trapped to provide proper drain-

age. See Figure 1.

COMPRESSORS

Units are shipped with compressor mountings factory-

adjusted and ready for operation.

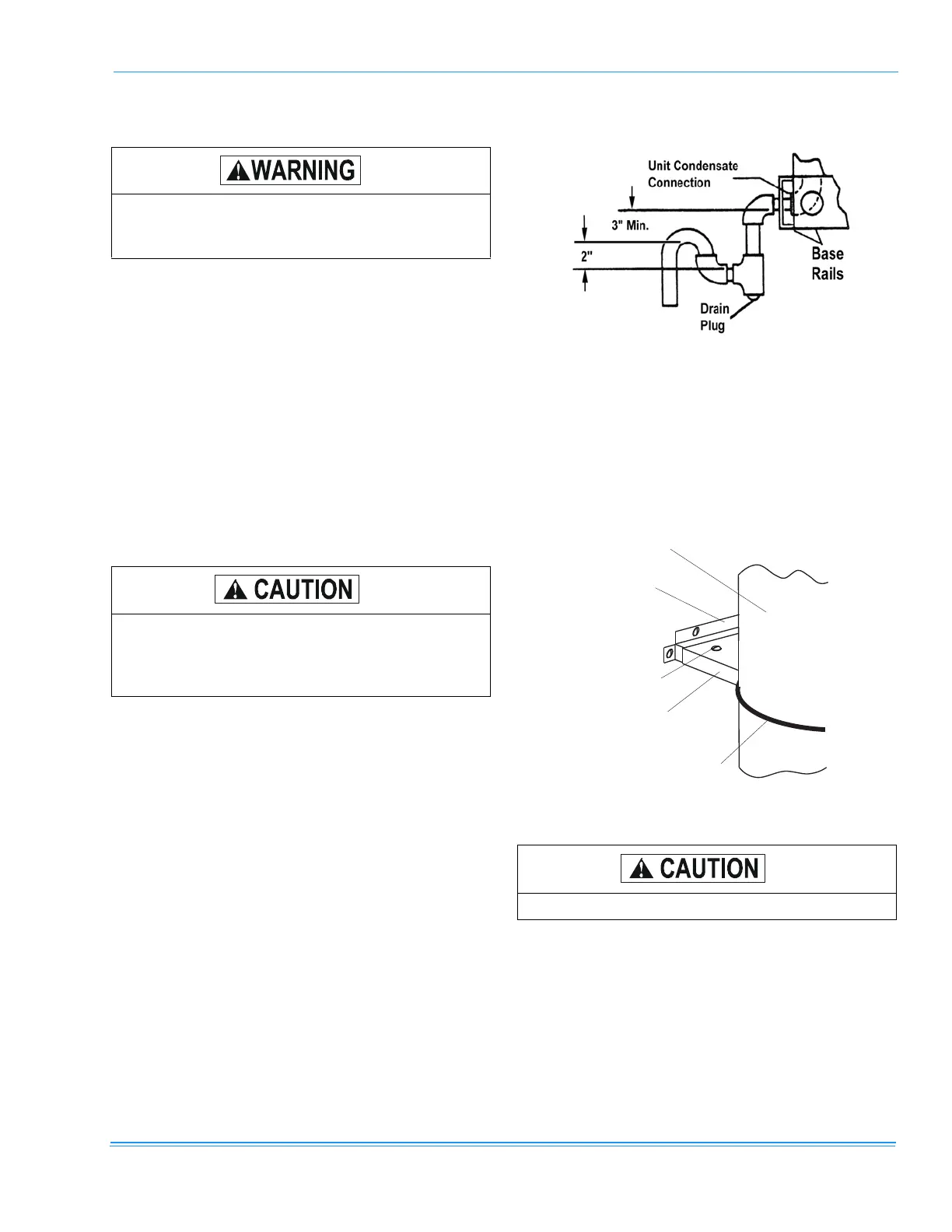

Units with scroll compressors have a shipping bracket

which must be removed after the unit is set in place.

See Figure 2.

FILTERS

One-inch or two-inch filters can be supplied with each

unit. Filters must always be installed ahead of the

evaporator coil and must be kept clean or replaced with

same size and type. Dirty filters will reduce the capacity

of the unit and will result in frosted coils or safety shut-

down. Minimum filter area and required sizes are

shown in Physical Data Table 8.

Do not permit overhanging structures or shrubs

to obstruct outdoor air discharge outlet, com-

bustion air inlet or vent outlets.

When fastening ductwork to side duct flanges

on unit, insert screws through duct flanges only.

DO NOT insert screws through casing. Outdoor

ductwork must be insulated and waterproofed.

FIGURE 1 - RECOMMENDED DRAIN PIPING

FIGURE 2 - COMPRESSOR RESTRAINING BRACKET

Do not loosen compressor mounting bolts.

WIRE TIE

(CUT AND

REMOVE)

MOUNTING

BRACKET TOP

(REMOVE)

MOUNTING

BRACKET BASE

REMOVE THESE

SCREWS (2)

COMPRESSOR

Loading...

Loading...