RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.200-IOM (DEC 11)

Page 11

OIL FILTER(S)

Use of filter elements other than

Frick may cause warranty claim

may to be denied.

The oil filter(s) and coalescer filter element(s) shipped with

the unit are best suited to ensure proper filtration and opera‑

tion of the system.

THERMOSYPHON OIL COOLING

Thermosyphon oil cooling is an economical, effective method

for cooling oil on screw compressor units. Ther mosyphon

cooling utilizes liquid refrigerant at condenser pressure and

temperature that is partially vaporized at the condenser tem‑

perature in a plate and shell vessel, cooling the oil to within

15°F of that temperature. The vapor, at condensing pressure,

is vented to the condenser inlet and reliquified. This method is

the most cost effective of all currently applied cooling systems

since no compres sor capacity is lost or compressor power

penalties in curred. The vapor from the cooler need only be

con densed, not compressed. Refrigerant flow to the cooler is

automatic, driven by the thermosyphon principle and cooling

flow increases as the oil inlet temperature rises.

EQUIPMENT ‑ The basic equipment required for a ther‑

mosyphon system consists of:

1. A source of liquid refrigerant at condensing pressure and

temperature, located in close proximity to the unit to mini mize

piping pressure drop. The liquid level in the refrigerant source

must be 6 to 8 feet minimum above the center of the oil cooler.

2. A plate and shell oil cooler with:

Plate Side: Oil 400 psi design

Shell Side: Refrigerant 400 psi design

Due to the many variations in refrigeration system design

and physical layout, several systems for assuring the above

criteria are possible.

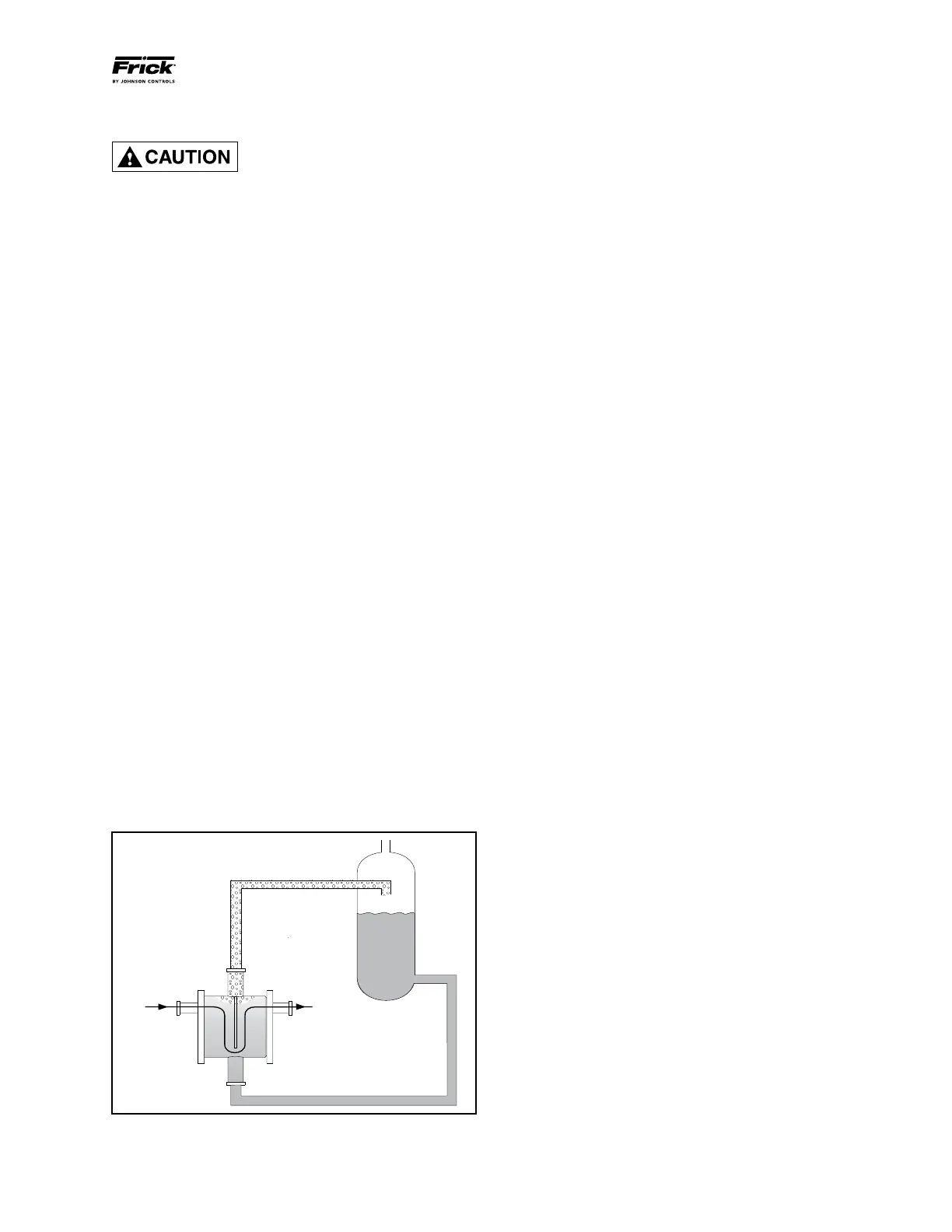

SYSTEM OPERATION ‑ Liquid refrigerant fills the cooler

shell side up to the Thermosyphon receiver liquid level. See

Figure 7.

Hot oil (above the liquid temperature) flowing through the

cooler will cause some of the refrigerant to boil and vaporize.

The vapor rises in the return line. The density of the refriger‑

ant liquid/vapor mixture in the return line is considerably less

than the density of the liquid in the supply line. This imbalance

provides a differential pressure that sustains a flow condi tion

to the oil cooler. This relationship involves:

1. Liquid height above the cooler.

2. Oil heat of rejection.

3. Cooler size and piping pressure drops.

Current thermosyphon systems are using two‑pass oil cool‑

ers and flow rates based on 3:1 overfeed.

The liquid/vapor returned from the cooler is separated in the

receiver. The vapor is vented to the condenser inlet and need

only be reliquified since it is still at condenser pressure.

OIL TEMPERATURE CONTROL ‑ Oil temperature will gen‑

erally run about 15 ‑ 35°F above condensing tempera ture.

In many cases, an oil temperature control is not required if

condensing temperature is above 65°F as oil tempera ture

can be allowed to float with condenser temperature.

Condensing Temperature: 65°F ‑ 105°F

Oil Temperature: 80°F ‑ 140°F

INSTALLATION ‑ The plate and shell type thermosyphon oil

cooler with oil‑side piping and a thermostatically controlled

mixing valve (if ordered) are factory mount ed and piped. The

customer must supply and install all piping and equip ment

located outside of the shaded area on the piping diagram

with consideration given to the following:

1. The refrigerant source, thermosyphon or system receiv er,

should be in close proximity to the unit to minimize piping

pressure drop.

2. The liquid level in the refrigerant source must be 6 to 8

feet minimum above the center of the oil cooler.

3. A safety valve should be installed if refrigerant isolation

valves are used for the oil cooler.

The component and piping arrangement shown in Figure 8, is

intended only to illustrate the operating principles of thermo‑

syphon oil cooling. Other component layouts may be better

suited to a specific installation. Refer to publication 070.900‑E

for additional information on Thermosyphon Oil Cooling.

HOT OIL IN

FROM

SEPARATOR

120-140 F

OIL OUT

O

TO SYSTEM CONDENSER

95 F

2.5#/FT

O

3

95 F

36#/FT

O

3

TS RECEIVER

Figure 7

Loading...

Loading...