RWB II ROTARY SCREW COMPRESSOR UNITS

GENERAL INFORMATION

070.200-IOM (DEC 11)

Page 3

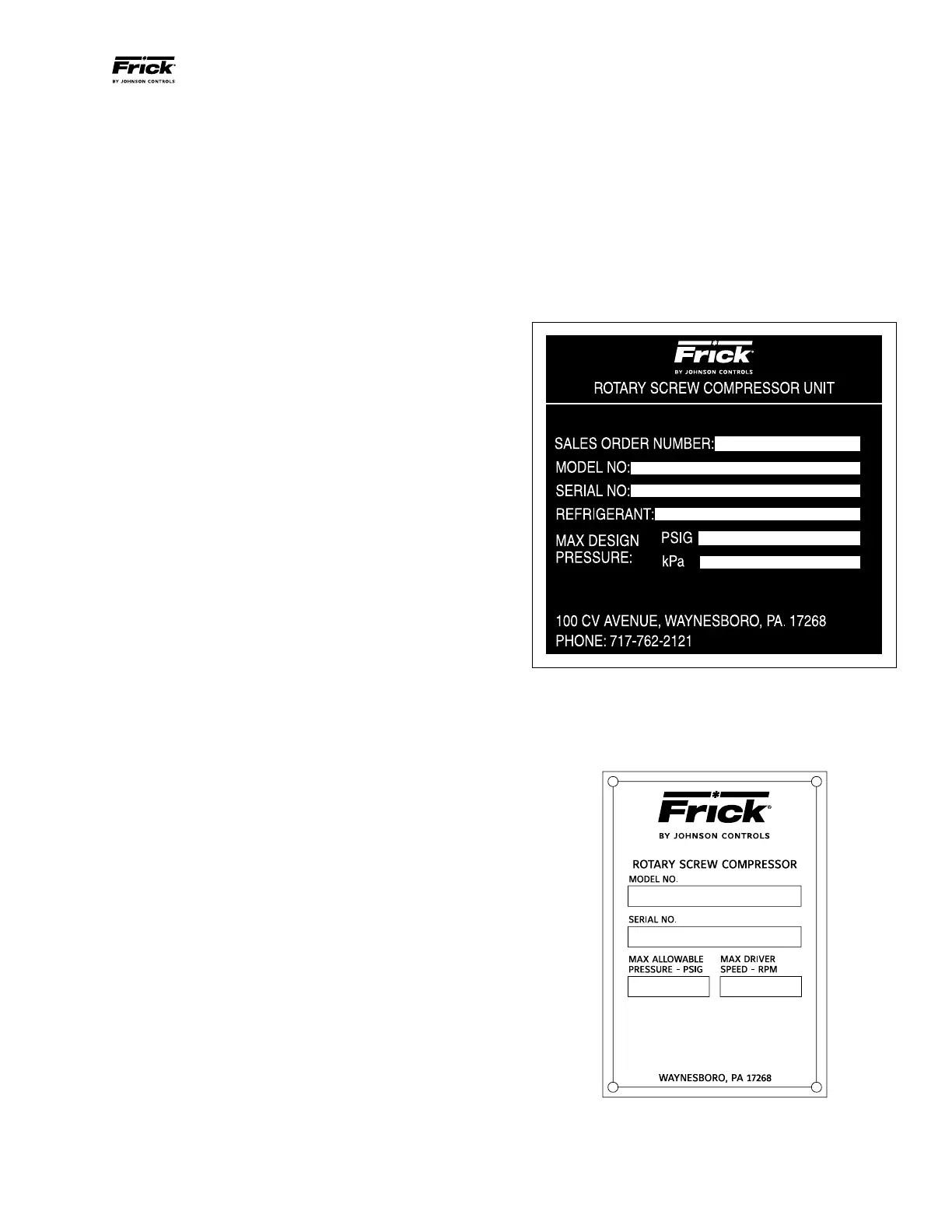

COMPRESSOR IDENTIFICATION

Each compressor has an identification data plate (see below),

containing compressor model and serial number mounted on

the compressor body.

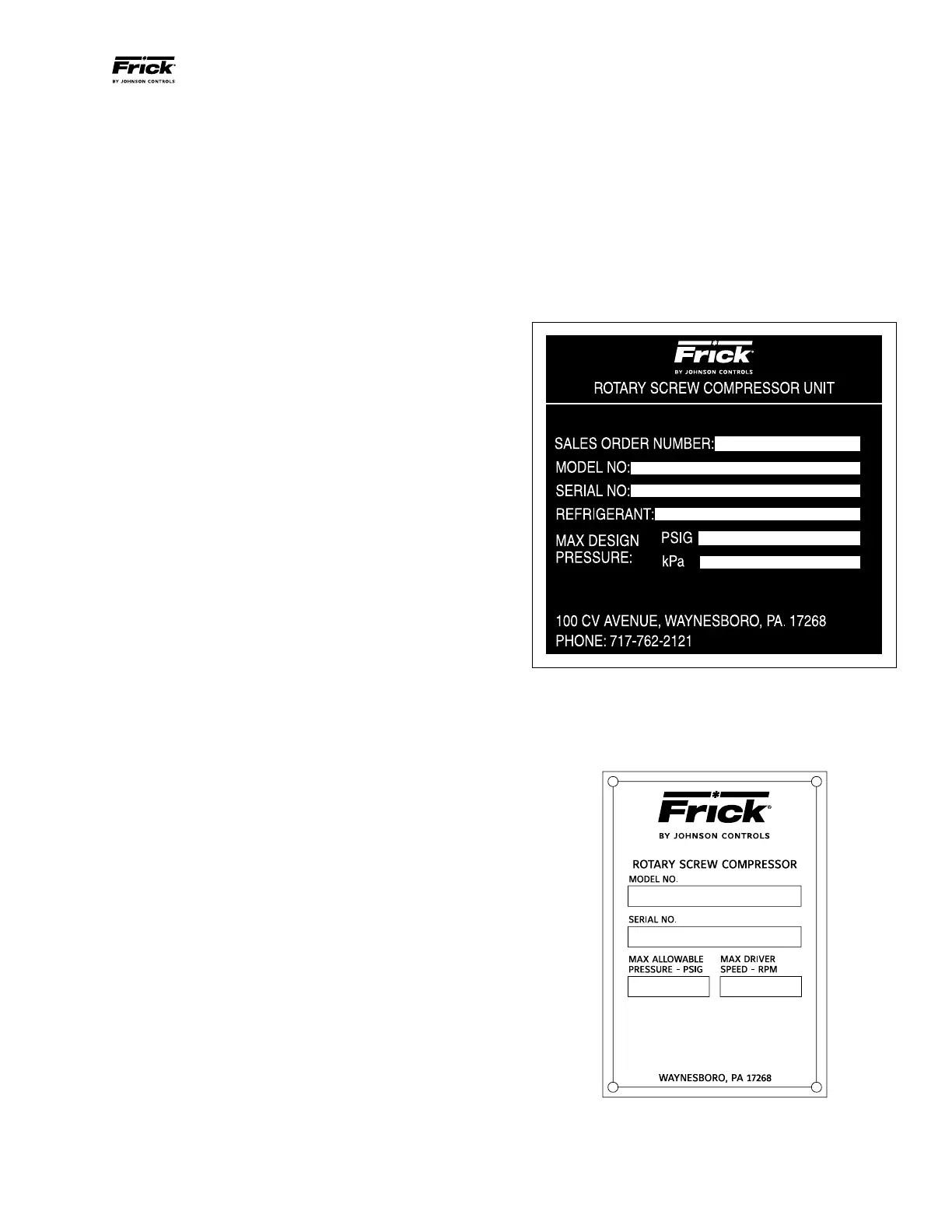

COMPRESSOR DATA PLATE

COMPRESSOR and UNIT IDENTIFICATION

Each compressor unit has 2 identifica tion data plates. The

compressor data plate containing compressor model and

serial number is mounted on the compressor body. The unit

data plate containing unit model, serial number and Frick

®

sales order number is mounted on the side of the Quantum

control panel.

NOTE: When inquiring about the compres sor or unit,

or ordering repair parts, provide the MODEL, SERIAL,

and FRICK

®

SALES ORDER NUMBERS from these data

plates.

PREFACE

This manual has been prepared to acquaint the owner and

serviceman with the INSTALLATION, OPERATION, and

MAIN TEN ANCE procedures recommended for Frick

®

RWB II

Rotary Screw Compres sor Units.

For information about the functions of the electrical control

panel, communications, specifications, and wiring diagrams,

see S90‑010 O, S90‑010 M, and 090‑010 CS for the Quan‑

tum panel.

It is most important that these units be properly applied to an

adequately controlled refrigeration system. Your authori zed

Frick representative should be con sulted for expert guidance

in this determination.

Proper performance and continued satisfaction with these

units is dependent upon:

CORRECT INSTALLATION

PROPER OPERATION

REGULAR, SYSTEMATIC MAINTENANCE

To ensure correct installation and application, the equip ment

must be properly selected and connected to a properly de‑

signed and installed system. The Engi neering plans, piping

layouts, etc. must be detailed in accor dance with the best

practices and local codes, such as those outlined in ASHRAE

literature.

A refrigeration compressor is a VAPOR PUMP. To be certain

that it is not being subjected to liquid refriger ant carryover it

is necessary that refriger ant controls are carefully selected

and in good operating condition; the piping is properly sized

and traps, if necessary, are correct ly arranged; the suction

line has an accumulator or slugging protec tion; that load

surges are known and provisions made for control; operating

cycles and de frost ing periods are reasonable; and that high

side condensers are sized within system and compressor

design limits.

It is recommended that the entering vapor temperature to the

compressor be superheated to 10°F above the refriger ant

saturation temperature. This assures that all refrigerant at

the compressor suction is in the vapor state.

DESIGN LIMITATIONS

The compressor units are designed for operation within

the pressure and temperature limits as shown in Frick Pub.

070.200‑SED.

JOB INSPECTION

Immediately upon arrival examine all crates, boxes and

exposed compressor and com ponent surfaces for dam age.

Unpack all items and check against shipping lists for any

possible shortage. Examine all items for damage in transit.

TRANSIT DAMAGE CLAIMS

All claims must be made by consignee. This is an ICC require‑

ment. Request immediate inspection by the agent of the carrier

and be sure the proper claim forms are execut ed.

Report damage or shortage claims im mediately to Johnson

Controls Inc.,Frick Sales Ad ministration Depart ment, in

Waynes boro, PA.

Loading...

Loading...