RWB II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.200-IOM (DEC 11)

Page 33

RECOMMENDED

MAINTENANCE PROGRAM

In order to obtain maximum compressor unit perform ance

and ensure reliable operation, a regular main tenance pro‑

gram should be followed.

The compressor unit should be checked daily for leaks, ab‑

normal vibration, noise, and proper operation. A log should

also be maintained. There should be continued monitor ing

of oil quality and oil analysis testing. In addition,

an analysis

of the unit’s vibration should be periodic ally made.

VIBRATION ANALYSIS

Periodic vibration analysis can be useful in detecting bear‑

ing wear and other mechanical failures. If vibration analysis

is used as a part of your preventive main tenance program,

take the following guidelines into consideration.

1. Always take vibration readings from exactly the same

places and at exactly the same percentage of load.

2. Use vibration readings taken from the new unit at start‑up

as the base line reference.

3. Evaluate vibration readings carefully as the instru ment

range and function used can vary. Findings can be easily

misinterpreted.

4. Vibration readings can be influenced by other equip ment

operating in the vicinity or connected to the same piping as

the unit.

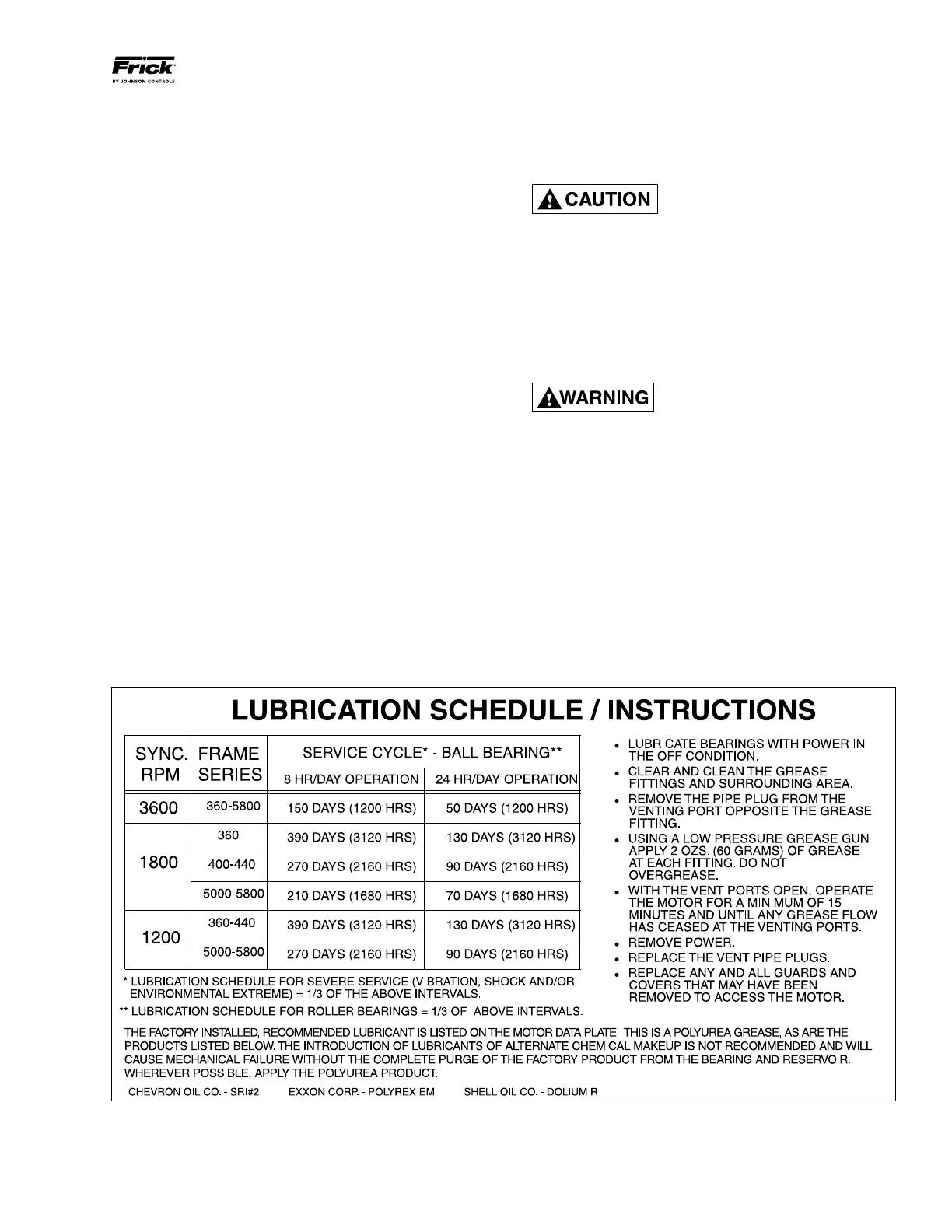

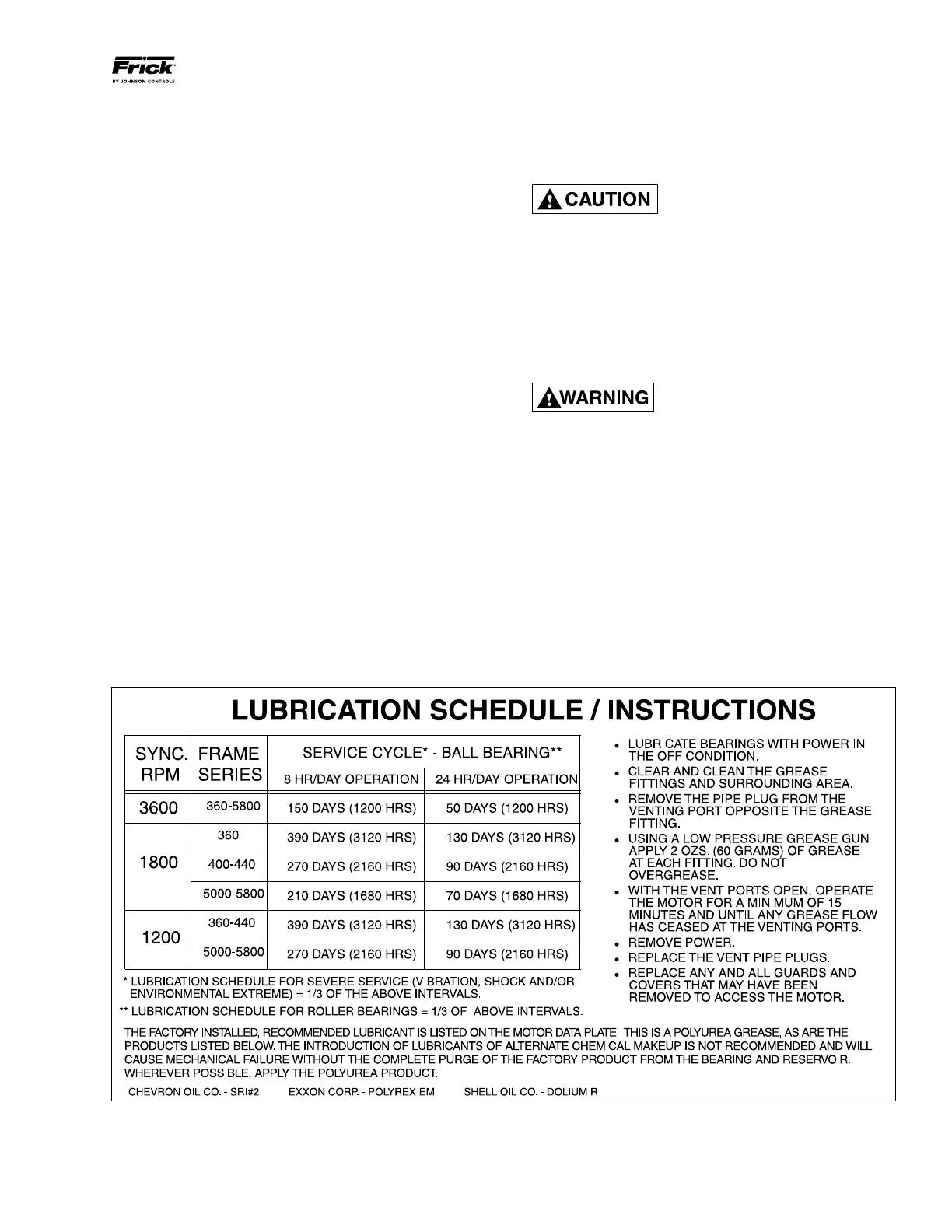

MOTOR BEARINGS

Follow the motor manufacturer’s maintenance recommenda‑

tions. See Figure 29.

Make sure the motor bearings are

properly lubricated before start-up

as required by the motor manuf ac-

turer.

OIL QUALITY and ANALYSIS

High quality refrigeration oil is necessary to ensure com‑

pressor longevity and reliability. Oil quality will rapidly de‑

teriorate in refrigeration systems containing moisture, air,

or other contaminants. In order to ensure the quality of the

refrigeration oil in the compressor unit.

DO NOT MIX OILS of different brands,

manufacturers, or types. Mixing of

oils may cause excessive oil foam-

ing, nuisance oil level cutouts, oil pressure loss, gas or

oil leakage and catastrophic compressor failure.

NOTE: The Frick oil charge shipped with the unit is the

best suited lubricant for the conditions specified at the

time of purchase. If there is any doubt due to the refriger-

ant, operating pressures, or temperatures, refer to Frick

Oil publication 160.802-SPC for guidance.

1. Only use Frick filter elements or warranty claim may

be denied.

2. Participate in a regular, periodic oil analysis program to

maintain oil and system integrity.

Figure 29

Loading...

Loading...